- 3003 anti-corrosion thermal insulation aluminum coil performance

- 3003 anti-corrosion insulation aluminum coil application fields

- 3003 anti-corrosion thermal insulation aluminum coil price

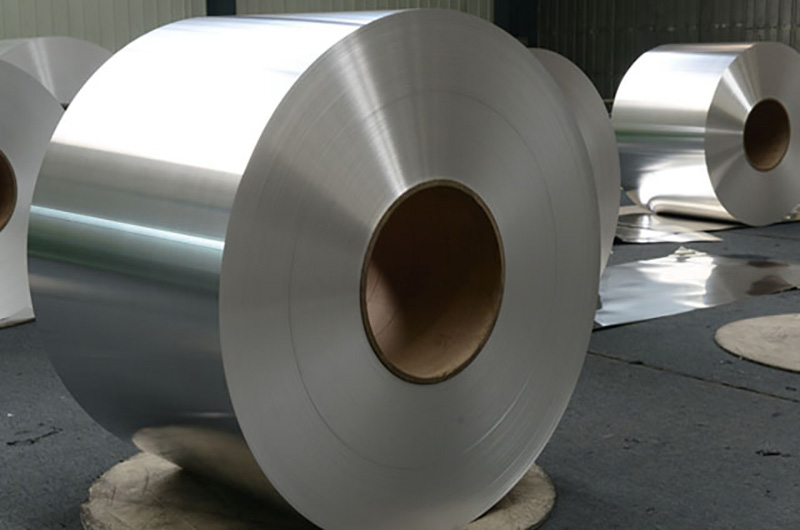

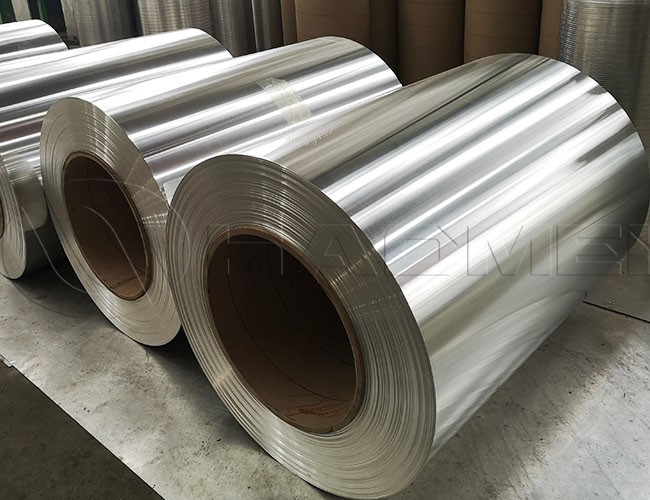

In recent years, the use of thermal insulation aluminum sheets has become more and more widespread. Aluminum alloy materials can be used for various pipeline insulation, equipment insulation, tank insulation, reactor tank insulation, etc. Models include 1060 insulation aluminum coil, 3003 insulation aluminum coil, The thickness ranges from 0.5-3.0mm. Compared with iron sheet, aluminum sheet has excellent anti-rust function.

3003 anti-corrosion thermal insulation aluminum coil performance

3003 anti-corrosion and thermal insulation aluminum coil is a special-purpose aluminum coil product, usually used in construction and industrial fields. Its main features include aluminum alloy model, anti-corrosion properties, thermal insulation performance, etc.

1. Aluminum alloy model (3003)

The model of aluminum coil is determined by its aluminum alloy composition, and in this case, "3003" is a common aluminum alloy model. This model indicates that the aluminum alloy mainly contains aluminum and other elements, of which manganese is the main alloying element. Common characteristics of 3003 aluminum alloy include:

- Good formability: Due to its suitable composition, 3003 alloy usually has superior formability and can be processed by cold, hot rolling and other processes.

- Corrosion resistance: Due to the manganese and other elements in the alloy, 3003 alloy usually has good corrosion resistance and is suitable for use in humid and corrosive environments.

2. Anti-corrosion properties

"3003 anti-corrosion thermal insulation aluminum coil" may undergo special anti-corrosion treatment during its manufacturing process to increase its corrosion resistance and durability. Such anti-corrosion properties may include:

- Surface treatment: The surface of aluminum coils may be anodized, spray-coated or otherwise chemically treated to form a protective film to improve corrosion resistance.

- Chemical resistance: The chemical resistance of aluminum alloys makes it widely used in industrial environments and can withstand the impact of a variety of chemicals.

3003 aluminum coil is an AL-Mn alloy with excellent anti-rust properties. It is also called anti-rust aluminum plate. Its strength is about 10% higher than that of 1100. It has good formability, weldability and corrosion resistance.

3003 aluminum coil is an alloy product with added manganese alloy element. Compared with 1060 aluminum coil, it has better anti-corrosion performance. In coastal or highly corrosive environments, it is recommended to use 3003 aluminum coil.

3. Insulation performance

3003 Anti-Corrosion Insulated Aluminum Coil" may be designed for thermal insulation applications where insulation performance is a key consideration. This includes:

- Thermal conductivity: As a metal, aluminum has good thermal conductivity, but through special design and treatment, it can reduce heat conduction and improve thermal insulation performance.

- Usage: May be used in building exterior wall insulation systems, insulation coverings of industrial equipment, etc. to help maintain temperature stability.

3003 anti-corrosion insulation aluminum coil application fields

3003 anti-corrosion and thermal insulation aluminum coils have various application scenarios in the construction and industrial fields:

3003 anti-corrosion thermal insulation aluminum coil for building exterior walls

3003 anti-corrosion thermal insulation aluminum coil is used in building exterior wall insulation systems to provide thermal insulation effect and anti-corrosion properties.

- Specifications: The specifications of the membrane required for building exterior walls usually involve the thickness, width and length of the membrane. These specifications will be based on the building design and exterior wall system needs.

- Temper: The Temper (condition) of the aluminum coil is also an important consideration. Temper may include O (soft), H14, H16, etc. The specific Temper selection will depend on the required strength and shape of the exterior wall membrane.

3003 anti-corrosion thermal insulation aluminum coil for industrial equipment

3003 anti-corrosion thermal insulation aluminum coil is used to cover the surface of industrial equipment, protect the equipment from corrosion, and provide thermal insulation effect.

- Specifications: Industrial equipment varies widely in size and shape, so the specifications of the roll will vary depending on the specific application. Thicker rolls may be required to provide better strength and protection.

- Temper: Industrial equipment may require higher strength materials, so the choice of Temper may be H14, H16 or higher status, depending on the use environment and requirements of the equipment.

3003 anti-corrosion thermal insulation aluminum coil price

The price of 3003 aluminum coils for pipe insulation has a certain relationship with the market price of aluminum ingots and processing fees. The price of aluminum ingots fluctuates every day, and the market price is not much different. The price advantage is not obvious, mainly in terms of product quality.

The price of aluminum coils is affected by many factors, including:

- Specifications: Different specifications (thickness, width, length) will affect the price.

- Market supply and demand: The supply and demand relationship in the market will also have an impact on prices.

- Manufacturers: Different manufacturers may have different pricing strategies, so it's best to contact the manufacturer directly for a specific quote.

The price of 3003 anti-corrosion thermal insulation aluminum coil may vary by region and market, the best way is to contact the supplier to obtain the most accurate price information.

Overall, this aluminum coil is a versatile material that plays an important role in the construction and industrial sectors through its special aluminum alloy models and anti-corrosion insulation properties.

Haomei Aluminum is a large-scale aluminum plate and coil manufacturer with many years of production experience and quality-oriented. The company's diligent pursuit of product quality has won a good market reputation for the company. Currently, Haomei Aluminum products are exported to many countries and regions.

Informations you may be interested in:

- Aluminum Coil for Power Plant Insulation

- Stucco embossed aluminum coil for pipe insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- Characteristics and storage precautions of aluminum coils for thermal insulation

- What are the benefits of aluminum insulation?

- Is aluminum a good thermal insulator?

- 1050 thermal insulation aluminum coil