- 3003 aluminum disc characteristics

- Why choose 2.4mm deep drawn 3003 aluminum disc for electric pressure cooker?

- Why choose the deep drawing process for the 3003 aluminum disc of the electric pressure cooker?

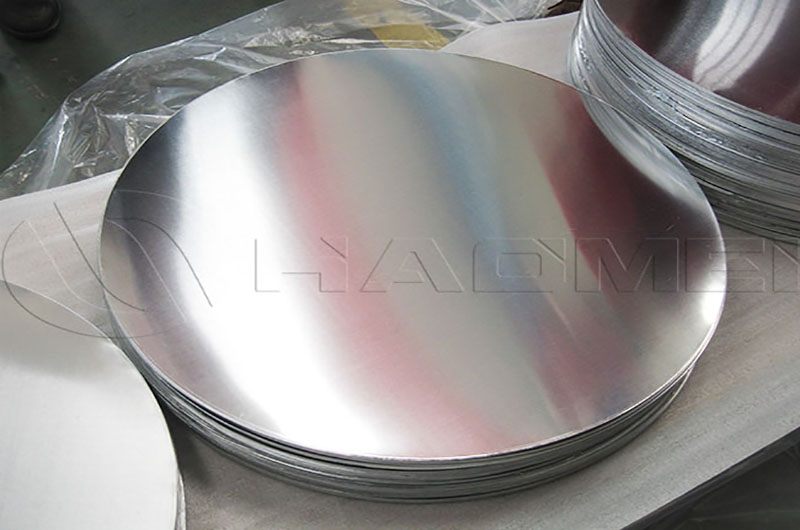

3003 aluminum discs are mainly used to manufacture pressure cookers, cookware, such as non-stick pans, hardware, etc. 3003 aluminum discs are the most widely used deep-drawn products, with high tensile strength, good ductility, anodized quality and deep-drawn quality, making them ideal for cookware.

Among modern kitchen equipment, the electric pressure cooker has become an indispensable cooking tool. To improve their performance and durability, manufacturers continue to seek advanced materials and processes. In this regard, 2.4mm deep drawn 3003 aluminum discs play a key role in the manufacture of electric pressure cookers.

3003 aluminum disc characteristics

3003 aluminum disc is a manganese alloy aluminum with good corrosion resistance and strength. This aluminum alloy is often used to make a variety of kitchen appliances because it is lightweight and easy to work with. In the manufacture of electric pressure cookers, lightweight materials are crucial to improve portability and ease of operation.

- 1. Excellent elongation and tensile strength.

- 2. Good processing performance, high stamping and drawing performance.

- 3. Gas welding, hydrogen welding, resistance welding, and brazing.

- 4. High plasticity, electrical conductivity and thermal conductivity.

- 5. Easy to perform various pressure processing, extension and bending.

Why choose 2.4mm deep drawn 3003 aluminum disc for electric pressure cooker?

The thickness of 2.4mm is carefully selected to ensure the strength of the disc and to ensure that the overall weight of the electric pressure cooker remains within a reasonable range.

The thickness of 2.4mm is enough to cope with use in high temperature and high pressure environments, ensuring that the disc will not be deformed or damaged during long-term use.

Deep drawn 3003 aluminum disc of other thicknesses for electric pressure cooker

| aluminum disc | thickness |

|---|---|

| deep drawn 3003 aluminum disc | 1.8mm |

| deep drawn 3004 aluminum disc | 2.0mm |

| deep drawn 3005 aluminum disc | 2.2mm |

| deep drawn 3006 aluminum disc | 2.4mm |

| deep drawn 3007 aluminum disc | 2.6mm |

| deep drawn 3008 aluminum disc | 2.8mm |

| deep drawn 3009 aluminum disc | 3.0mm |

| deep drawn 3010 aluminum disc | 3.2mm |

| deep drawn 3011 aluminum disc | 3.5mm |

| deep drawn 3012 aluminum disc | 4.0mm |

| Aluminium Disc Type | Final Products |

|---|---|

| 2mm - 3mm 1060 O, H12 Aluminium Disc | Fry Pans , Pizza Pans , Electric Skillets |

| 2mm - 4mm 3003 O Aluminium Disc | Pressure Cookers, Rice Cookers |

| 0.7mm - 2mm 1100 O Aluminium Disc | Stock Pots |

| 3mm - 5mm 1100 O Aluminium Disc | Cookware Bottom, Stainless Cookware, Bottom Plates |

| 2mm - 4mm 1100 3003 O Aluminium Disc | Coated Cookware |

Why choose the deep drawing process for the 3003 aluminum disc of the electric pressure cooker?

The deep drawing process is one of the key steps in manufacturing these aluminum discs. This process allows flat aluminum material to be formed into the desired shape through mechanical force and molds without compromising its physical properties.

The deep drawing process not only ensures the uniformity and consistency of the 3003 aluminum disc, but also increases its compressive strength, allowing it to withstand the high pressure generated inside the electric pressure cooker.

The thermal conductivity of 3003 aluminum is also one of the reasons for choosing this material in electric pressure cookers. It can conduct heat quickly, allowing the electric pressure cooker to heat food evenly during the cooking process and improve cooking efficiency. At the same time, this aluminum alloy is also resistant to extreme temperatures, ensuring that the disc operates stably and reliably in a variety of cooking environments.

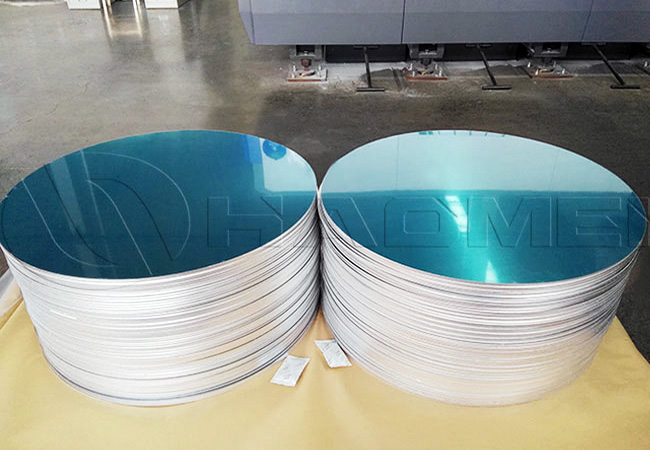

Haomei Aluminum's specialty is deep drawing quality, strictly controlling grain size to minimize the "orange peel effect" which is a rough surface, like the surface of an orange peel, usually after deep drawing occur.

Haomei Aluminum strictly controls chemical and thermal treatments to maximize the material's elongation, giving the material greater tensile strength.

Overall, the application of 2.4mm deep drawn 3003 aluminum discs in electric pressure cookers not only improves the performance and durability of electric pressure cookers, but also provides users with a more convenient and efficient cooking experience. This choice of materials and use of craftsmanship combine to create more advanced and reliable cooking solutions for modern kitchens.

Informations you may be interested in:

- 1060 Aluminum Circle Discs Blanks for Pot

- 1060 Aluminum Circle Discs for Cookware

- Pizza Trays 3003 Aluminum Disc

- Food grade 3003 aluminum disc: Electric frying pan 3003 aluminum disc

- Round 3003 Aluminum Discs Deep Spining Punching Aluminum Barrel Materials

- 3003 aluminum circle for non stick pan

- 1060 3003 Aluminum circle for kettle

- Polished DC 3003 Aluminum Circles for Baking Tray

- Aluminium circle for making pot 1060 3003

- 3003 Aluminum Circle for Cookware