- The structural composition of non-stick pans

- Learn about 3003 aluminum circle

- Specifications for 3003 aluminum discs for non-stick pans

- Advantages of using 3003 aluminum rounds for non-stick pans

- Classification of coated aluminum discs for non-stick pans

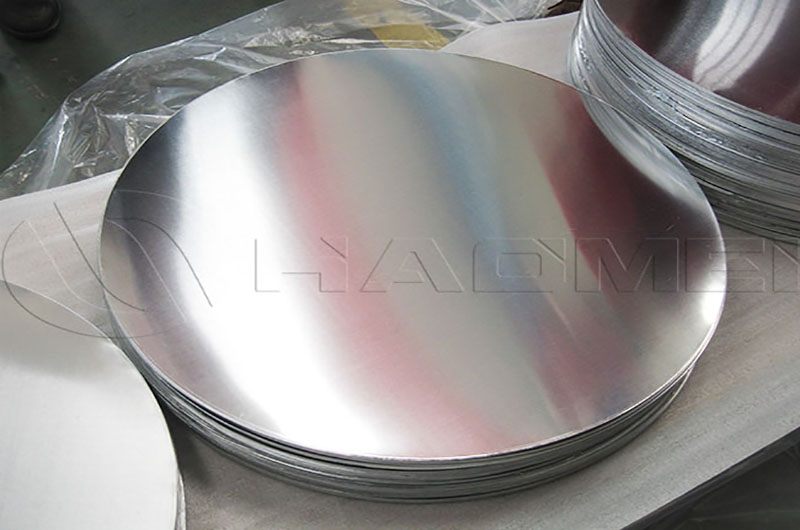

3003 aluminum circle has become an important part of the modern kitchen, providing convenience and ease in cooking. Among the various materials used in nonstick construction, 3003 aluminum rims are popular for their unique properties that contribute to the overall quality of the cookware.

Alloy 3003 aluminum round for non-stick pans is non-toxic, odorless, non-corrosive, high strength, long service life, safe and hygienic. 3003 series aluminum rounds are commonly used products in the aluminum-manganese alloy series. Due to the presence of manganese alloy elements, 3003 aluminum rounds have excellent anti-rust properties.

At present, nearly 50% of the pots sold in the cookware market are aluminum alloy non-stick pots. Non-stick pans made of 3003 aluminum rounds have better advantages than iron pans. They are non-stick and smoke-free. They can be used on induction cookers and are convenient and easy to clean. Aluminum is more commonly used in nonstick pans.

The structural composition of non-stick pans

- Base material: Aluminum alloy is usually used, such as 3003 aluminum alloy. Aluminum is lightweight and has good thermal conductivity, so it is often used to make pots and pans.

- Non-stick coating: A non-stick coating is often applied to the surface of a pan to prevent food from sticking to the bottom of the pan. These coatings are usually polytetrafluoroethylene (PTFE) under the brand name Teflon, or ceramic coatings.

- Bottom coating: Some nonstick pans may have a material on the bottom that conducts heat better, such as aluminum or stainless steel, to improve heat distribution across the bottom of the pan.

Discs of 3003 aluminum alloy are often chosen as the main body material for non-stick pans to provide good thermal conductivity, lightweight and durability. However, exact manufacturing and design may vary by manufacturer.

Learn about 3003 aluminum circle

3003 aluminum is a widely used alloy known for its excellent formability, corrosion resistance, and moderate strength. Adding manganese to the aluminum composition increases its strength while maintaining its ductility, making it suitable for a variety of applications, including cookware.

Specifications for 3003 aluminum discs for non-stick pans

| Product Name | round aluminum metal circle / disc for non stick pan |

|---|---|

| Type | Aluminum Circle |

| Surface | Mill Finished, Flat Clean Surface Without Scratches, Wholes, Oil dirty, Oxidation, Cutting Edge No Burrs |

| Thickness | 0.15-7mm |

| Width | 50-1200mm |

| Packaging | Standard Export Packing Or As Client's Requirement |

| Certification | ISO9001, FDA, IAF, CNAS |

| Color | AS REQUIREMENT |

One of the main reasons to choose 3003 aluminum discs for nonstick pans is their anti-stick properties. When treated properly, aluminum's smooth surface can provide an ideal base for a nonstick coating. This feature ensures food releases easily from the pot, simplifying the cooking process and making cleanup a breeze.

Advantages of using 3003 aluminum rounds for non-stick pans

- 1. Strong anti-rust performance.

- 2. Smooth surface, good plasticity, and pressure resistance;

- 3. Excellent molding performance, high corrosion resistance, excellent weldability and electrical conductivity, with strength higher than 1100.

In addition, 3003 aluminum discs also have the following advantages:

Excellent thermal conductivity

3003 aluminum has excellent thermal conductivity, which is a key factor in cookware performance. This distributes heat evenly over the surface of the pan, preventing hot spots that can cause uneven cooking. Uniform temperature distribution ensures food cooks evenly, resulting in better flavor and texture.

Lightweight and durable

Made from 3003 aluminum rings, non-stick pans are lightweight and easy to handle and maneuver in the kitchen. Despite their lightweight, these pans are extremely durable and able to withstand the rigors of daily cooking. The combination of lightweight design and durability makes 3003 aluminum rings an attractive choice for those looking for practical and durable cookware.

Good corrosion resistance

3003 aluminum is known for its corrosion resistance, ensuring your nonstick pans stay in good condition for the long term. This resistance protects the aluminum surface from reacting with acidic or alkaline ingredients, extending the life of your cookware.

Easy maintenance

Maintaining a nonstick pan made of 3003 aluminum rings is easy. The non-stick coating combined with the corrosion-resistant properties of aluminum makes the cleaning process quick and easy. This ease of maintenance is especially attractive to busy people looking for efficient kitchen tools.

Classification of coated aluminum discs for non-stick pans

Nonstick pans are usually classified according to the type and material of the aluminum disc that covers the bottom. The design and material of these aluminum discs can affect the performance and durability of the pot. Here are some possible classifications:

Plain 3003 aluminum disc: Some non-stick pans use a plain 3003 aluminum disc for the bottom. This design is generally more affordable, but may not be as good as other options in terms of heat distribution and durability.

Hard Anodized 3003 Aluminum Disc: This type of 3003 aluminum disc has an anodized surface to make it harder and wear-resistant. They generally have better durability and heat dispersion, but are relatively more expensive.

Stainless Steel-Coated 3003 Aluminum Discs: Some nonstick pans use stainless steel-coated 3003 aluminum discs to provide better corrosion resistance and durability. This design is usually more expensive but offers better performance and durability.

Copper-Coated 3003 Aluminum Discs: Some high-end nonstick pans may use copper-coated 3003 aluminum discs. Copper has excellent thermal conductivity and can improve the heat distribution of the pot. These pots tend to be more expensive, but may offer better cooking performance.

Choosing between different types of aluminum discs depends on your nonstick performance needs and your budget. It should be noted that no matter what type of non-stick pan you use, you should use hard tools with caution to avoid scratching and damaging the non-stick coating.

Informations you may be interested in:

- 1060 Aluminum Circle Discs Blanks for Pot

- 1060 Aluminum Circle Discs for Cookware

- 2.4mm deep drawn 3003 aluminum disc for electric pressure cooker

- Pizza Trays 3003 Aluminum Disc

- Food grade 3003 aluminum disc: Electric frying pan 3003 aluminum disc

- Round 3003 Aluminum Discs Deep Spining Punching Aluminum Barrel Materials

- 1060 3003 Aluminum circle for kettle

- Polished DC 3003 Aluminum Circles for Baking Tray

- Aluminium circle for making pot 1060 3003

- 3003 Aluminum Circle for Cookware