- Mechanical Performance

- Chemical Composition

- Strength

- Corrosion Resistance

- Machinability

- Application Site

- Cost

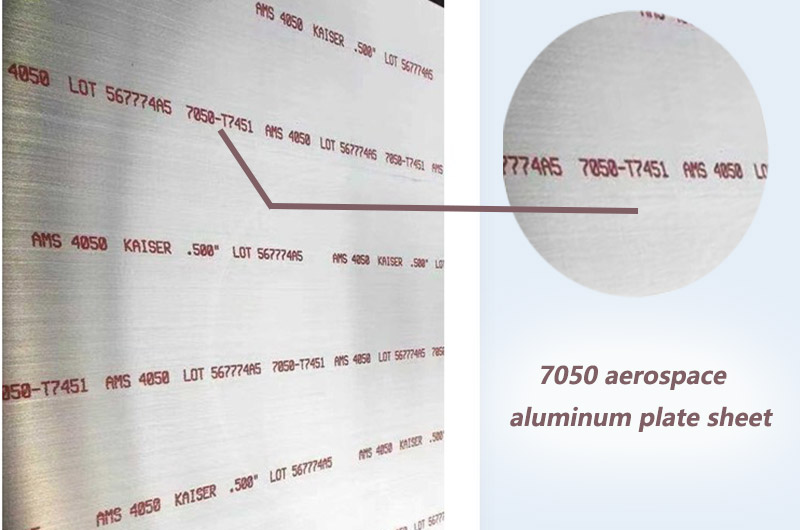

2024 and 7075 aluminum alloys are commonly used in aerospace applications due to their high strength-to-weight ratio and excellent fatigue resistance. However, there are some key differences between the two alloys.

2024 aluminum alloy has copper as the main alloying element and contains small amounts of magnesium, manganese and zinc. It is known for its high strength and good machinability, but has low corrosion resistance compared to other aluminum alloys. It is commonly used in aircraft structures and wing components.

On the other hand, 7075 aluminum alloy contains zinc as its main alloying element, along with small amounts of copper, magnesium, and chromium. It is known for its high strength and toughness and excellent resistance to fatigue. It is commonly used in high stress applications such as aircraft fuselages, wings and structural components.

In terms of specific performance, the 7075 aluminum alloy has a higher strength-to-weight ratio and better corrosion resistance than the 2024 aluminum alloy. However, 2024 aluminum alloy has better machinability and lower cost than 7075 aluminum alloy.

Mechanical Performance

The value is for reference only, and the specific value may vary due to factors such as manufacturer and process. When selecting a specific aluminum alloy material, it is necessary to consider its actual performance and requirements in the application, and comprehensively consider various factors.

| Property | 2024 Aluminum Plate | 7075 Aluminum Plate |

|---|---|---|

| Density | 2.78 g/cm³ | 2.81 g/cm³ |

| Young's Modulus | 73.1 GPa | 71.7 GPa |

| Yield Strength | 324-414 MPa | 524 MPa |

| Tensile Strength | 470-510 MPa | 572-595 MPa |

| Hardness (Brinell) | 120 | 150-160 |

| Fatigue Strength | Lower | Higher |

| Toughness | Higher | Lower |

Chemical Composition

The 2024 aerospace aluminum alloy sheet mainly contains copper, a small amount of magnesium, manganese and zinc as alloying elements. 7075 aerospace aluminum alloy sheet mainly contains zinc, a small amount of copper, magnesium and chromium as alloying elements.

| Element | 2024 Aerospace Aluminum Plate | 7075 Aerospace Aluminum Plate |

|---|---|---|

| Aluminum (Al) | 90.0% min | 87.1% min |

| Copper (Cu) | 3.8-4.9% | 1.2-2.0% |

| Magnesium (Mg) | 1.2-1.8% | 2.1-2.9% |

| Manganese (Mn) | 0.3-0.9% | 0.3% max |

| Zinc (Zn) | 0.25% max | 5.1-6.1% |

| Chromium (Cr) | 0.1% max | 0.18-0.28% |

| Iron (Fe) | 0.5% max | 0.5% max |

| Silicon (Si) | 0.5% max | 0.4% max |

| Titanium (Ti) | 0.15% max | 0.2% max |

| Other Elements | 0.05% max | 0.05% max |

Strength

7075 aerospace aluminum alloy plate has higher strength, higher tensile strength and higher hardness than 2024 aerospace aluminum alloy plate.

7075 aluminum alloy is generally regarded as a high-strength aluminum alloy, which also has better fatigue strength and toughness.

| Characteristics | 2024 Aluminum Alloy Plate | 7075 Aluminum Alloy Plate |

|---|---|---|

| Yield Strength | 324-414 MPa | 524 MPa |

| Tensile Strength | 470-510 MPa | 572-595 MPa |

| Fatigue Strength | Lower | Higher |

| Toughness | Higher | Lower |

Corrosion Resistance

The 7075 aerospace aluminum alloy plate has better corrosion resistance and can maintain the performance of the material in harsh environments, while the 2024 aerospace aluminum alloy plate is poor.

| Material | Corrosion Resistance |

|---|---|

| 2024 Aerospace Aluminum Alloy Plate | Good |

| 7075 Aerospace Aluminum Alloy Plate | Very Good |

Corrosion resistance depends on many factors, including service conditions, material handling, surface coatings, and more. Therefore, the above information is for reference only and does not represent performance in all situations. If you need more detailed and accurate information, please consult a professional.

Machinability

The 2024 aerospace aluminum alloy plate has better machinability, and is easier to cut and form, while the 7075 aerospace aluminum alloy plate is more difficult to process.

| Characteristics | 2024 Aluminum Alloy Plate | 7075 Aluminum Alloy Plate |

|---|---|---|

| Machinability | Good | Fair |

| Processing | Easy to forge, roll and stretch | Requires higher cutting speeds and appropriate cutting lubricants for machining |

2024 aluminum alloy has good processing performance, but due to its high copper content, it is necessary to pay attention to the temperature control of heat treatment and cooling during processing to prevent excessive residual stress and deformation.

Due to its high hardness and strength, 7075 aluminum alloy is difficult to process, but it has good machinability and cutting edge life. In addition, 7075 aluminum alloy also requires heat treatment to obtain the best mechanical properties.

Application Site

The specific application site depends on many factors, such as design requirements, performance requirements, cost, and so on. Therefore, the following information is for informational purposes only and does not represent application in all situations. If you need more detailed and accurate information, please consult Haomei Aluminum.

| Material | Application Areas |

|---|---|

| 2024 Aerospace Aluminum Alloy Plate | Aircraft fuselage, fuel tanks, wings, landing gear, wheels, engine components, propellers |

| 7075 Aerospace Aluminum Alloy Plate | Aircraft fuselage, wings, propellers, landing gear, wheels, missile components, spacecraft components |

Cost

The cost of 2024 aerospace aluminum alloy plate is lower than that of 7075 aerospace aluminum alloy plate.

The cost of 2024 and 7075 aerospace aluminum alloy plates is relatively high, but the cost of 7075 aluminum alloy is slightly higher.

Due to its high copper content, 2024 aluminum alloy is more difficult to process, so its price is usually slightly higher than other aluminum alloys. 7075 aluminum alloy is more expensive to manufacture due to its higher strength and hardness, so its price is correspondingly higher.

There are differences between 2024 aerospace aluminum alloy plate and 7075 aerospace aluminum alloy plate in terms of strength, corrosion resistance, machinability and cost, which material to choose depends on the requirements of specific applications. If you need higher strength, better corrosion resistance and higher fatigue resistance, you should choose 7075 aerospace aluminum alloy plate. If you need better machinability and lower cost, you should choose 2024 aerospace aluminum alloy plate.

Informations you may be interested in: