- 1600mm 1060 Aluminum Discs Round Circles for Solar Reflector Advantages

- 1060 Aluminum Discs Round Circles for Solar Reflector Specifications

- 1060 Aluminium Discs Round Circles for Solar Reflector Typical Diameter

- Solar Reflector Requirements for 1060 Aluminum Discs Round Circles

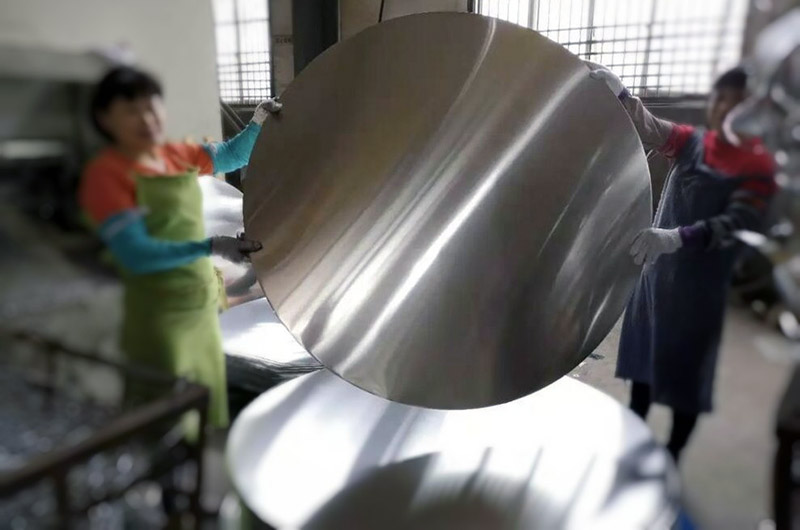

1600mm 1060 Aluminum Disc Ring is a round metal sheet made of high-purity 1060 aluminum material with a diameter of up to 1600 mm. This size design makes it an ideal size for solar reflectors, ensuring that the maximum amount of sunlight is captured and focused on the collector system.

1060 aluminum discs are usually used in solar reflectors to make the reflective surface or reflective surface of the reflector, that is, the surface part of the reflector, which plays a role in concentrating and focusing the sun's rays.

As one of the clean and renewable energy sources, solar energy continues to receive attention and development worldwide. In solar energy utilization technology, reflectors are an important component, used to focus sunlight and improve the efficiency of solar panels.

In the manufacture of reflectors, 1060 aluminum discs are favored for their superior performance and have become one of the ideal choices for solar reflectors.

1060 aluminum disc is a pure aluminum disc with good processing performance, electrical conductivity and thermal conductivity. In addition, the 1060 aluminum disc has high strength and good corrosion resistance, which makes it excellent in the manufacture of solar reflectors.

1600mm 1060 Aluminum Discs Round Circles for Solar Reflector Advantages

- High light reflectivity: The surface of the 1060 aluminum disc has been specially treated to have a high light reflectivity, which can reflect the sun's rays to the target area more effectively and improve the energy absorption efficiency of the solar panel.

- Good processing performance: 1060 aluminum discs are easy to process into various shapes and sizes, which can meet the needs of different reflector designs. This flexibility makes it an ideal material for fabricating complex reflector structures.

- Lightweight design: The 1060 aluminum disc has a lighter weight than other materials, which helps reduce the overall weight of the solar reflector and improves the device's portability and installation flexibility.

- Corrosion resistance: Because the 1060 aluminum disc has good corrosion resistance, it can better cope with complex outdoor environmental conditions and extend the service life of the solar reflector.

- Environmentally friendly and sustainable: The 1060 aluminum disc is a recyclable material, meets the requirements of environmental protection and sustainable development, and is consistent with the clean energy concept of solar energy.

1060 Aluminum Discs Round Circles for Solar Reflector Specifications

1060 Aluminum Discs Round Circles undergo precision processing to ensure that their surfaces are smooth and flat, and can accurately reflect sunlight.

The precise diameter and thin thickness design of 1060 Aluminum Discs Round Circles help maximize the reflection effect of light, ensuring that the solar system can obtain sufficient energy.

Thickness: Usually between 0.3mm and 5.0mm, the specific thickness selection depends on the structural requirements of the reflector and the required strength and weight.

1060 Aluminium Discs Round Circles for Solar Reflector Typical Diameter

| Aluminium Discs | diameter |

|---|---|

| 1060 Aluminium Discs Round Circles | 1600mm |

| 1060 Aluminium Discs Round Circles | 1500mm |

| 1060 Aluminium Discs Round Circles | 1400mm |

| 1060 Aluminium Discs Round Circles | 1300mm |

| 1060 Aluminium Discs Round Circles | 1200mm |

Solar Reflector Requirements for 1060 Aluminum Discs Round Circles

Solar reflectors usually have some specific requirements for 1060 Aluminum Discs Round Circles to ensure good performance and efficiency of the reflector in use. Here are some possible requirements:

- High Reflectivity: The surface of 1060 Aluminum Discs Round Circles should be highly reflective to maximize the reflection of incident sunlight. To achieve this, surface preparation and polishing are key steps.

- Surface Smoothness: To minimize light scattering and absorption losses, the surface of the aluminum disc should be extremely smooth. Polishing and surface treatments can be used to ensure surface smoothness.

- Dimensional and geometric accuracy: The design of reflectors often has specific requirements for geometric size and shape. 1060 Aluminum Discs Round Circles need to have an accurate diameter, flat surface, and consistent thickness to ensure reflector accuracy.

- Workability: 1060 aluminum discs should have good workability to allow for cutting, polishing and other necessary processing steps during the manufacturing process.

- Thermal Properties: Considering the high temperature of sunlight, 1060 Aluminum Discs Round Circles need to have good thermal conductivity to ensure that the heat of sunlight is quickly transferred.

These requirements may vary depending on the specific solar reflector design and application.

In the rapid development of the solar energy industry, 1060 aluminum discs, as the key material of solar reflectors, have made positive contributions to the improvement of solar energy utilization technology through its superior characteristics. Its high light reflectivity, good processing performance, lightweight design, corrosion resistance and environmental sustainability make it one of the preferred materials in reflector manufacturing, promoting technological innovation and application promotion in the solar field.

Informations you may be interested in: