- Why do signboards use 1050 aluminum coils?

- 1050 aluminum coil used for sign panels Specifications

- 1050 aluminum coil used for sign panels applications

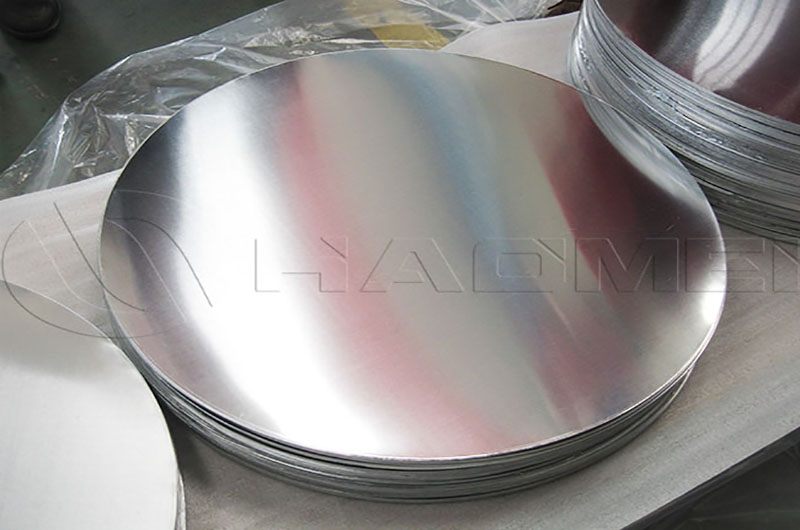

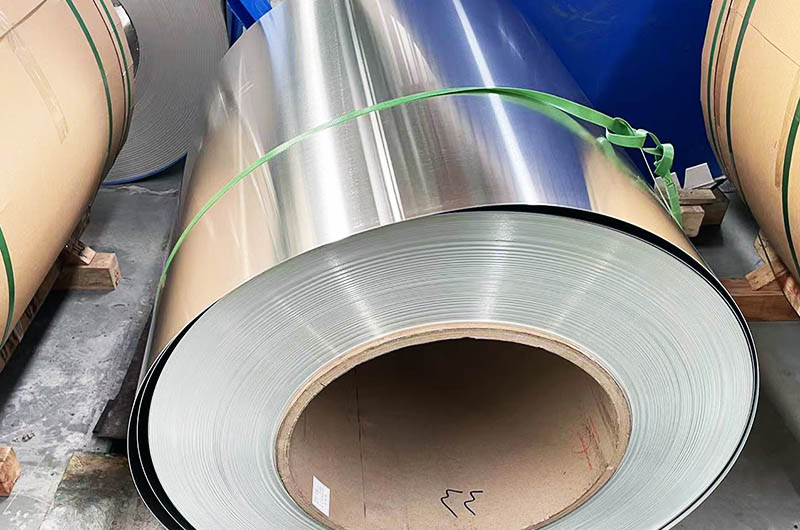

1050 aluminum coils are commonly used to make sign boards. 1050 aluminum alloy has good machinability and corrosion resistance, making it one of the ideal materials for manufacturing various signs and signage. This aluminum coil is commonly used in applications such as traffic signs, billboards, street signs, and more.

Why do signboards use 1050 aluminum coils?

Good workability: 1050 aluminum alloy has good workability and is easy to cut, shape and process into signs of various shapes. This makes it easy to manufacture sign boards to meet different design requirements.

Corrosion Resistance: 1050 aluminum alloy has good corrosion resistance, which is a crucial characteristic when placing signage in outdoor environments. Anti-corrosion properties help signs maintain good appearance and performance over time.

Lightweight: Aluminum is a relatively lightweight material, which makes the signs relatively lightweight and easy to install and transport.

Surface Treatment: 1050 aluminum coil can have different surface treatments, such as anodizing or coating, to increase its weather resistance and appearance. This helps the sign maintain a stable appearance in all weather conditions.

Economical and affordable: 1050 aluminum coils are relatively affordable, which can reduce manufacturing costs when mass-producing signs.

These properties of 1050 aluminum coil make it an ideal choice for manufacturing sign boards.

1050 aluminum coil used for sign panels Specifications

The specifications of sign boards using 1050 aluminum coils will vary based on specific manufacturing requirements and design needs. Generally speaking, the specifications of the sign board may include the following aspects:

Thickness: The thickness of the sign board can vary depending on the requirements of the design and use. Typically, sign board thickness may range from 0.5mm to 3mm, with the specific choice depending on the size and purpose of the sign.

Width and Length: Sign board width and length will also vary depending on specific design requirements. Typically, these dimensions are affected by the size, shape, and amount of information that needs to be conveyed.

Coating or surface treatment: If you need to increase the weather resistance and appearance of your sign board, you can choose to coat or surface treat the 1050 aluminum coil. This may include anodizing, spray coating, etc. The color of the coating can also be selected according to the design and marking requirements of the sign.

Hardness: The hardness of sign board usually needs to be moderate to make it easy to process into various shapes while maintaining sufficient stability and durability.

Specific specifications will vary by manufacturer and project. If you have specific project needs, it is recommended to contact the manufacturer or supplier to obtain customized 1050 aluminum coil specifications to ensure that your specific needs are met.

1050 aluminum coil used for sign panels applications

1050 aluminum coil for traffic signs

- Specifications: Usually 0.8mm to 2mm 1050 aluminum coil is used, the specific thickness depends on the size and requirements of the sign.

- Temper: Generally, H14 or H24 aluminum coils are often used in traffic signs to ensure sufficient hardness and strength.

1050 aluminum coil for billboards

- Specifications: The specifications of billboards may vary depending on size and design. Generally, you can choose aluminum coils from 0.8 mm to 3 mm.

- Temper: Aluminum coils in H18 condition may be used in billboards to provide higher hardness and strength.

1050 aluminum coil for street signs

- Size: The size of street signs is usually larger, so thicker aluminum coils may be required, generally between 1.5mm and 3mm.

- Temper: Aluminum coils in H14 or H24 condition are also more common in street sign manufacturing to balance hardness and workability.

These are general examples only and may vary in practice. The choice of Temper usually depends on the required mechanical properties and processing properties.

It is important to note that the selection of specifications and Temper is also affected by local standards and regulations, so it is best to follow the corresponding industry standards when selecting.

If you have specific project needs, it is recommended to further communicate with the aluminum coil manufacturer or supplier to obtain customized 1050 aluminum coil specifications and Temper recommendations.