- Learn about Aluminum Foil 1050

- Other ways of using aluminum foil in air conditioners

- 1050 air conditioner aluminum foil thermal conductivity

- Corrosion resistance of 1050 air conditioner aluminum foil

- 1050 air conditioner aluminum foil is lightweight and formable

- Energy Efficiency Reflectivity

- Easy to install and maintain

- Recyclability and sustainability

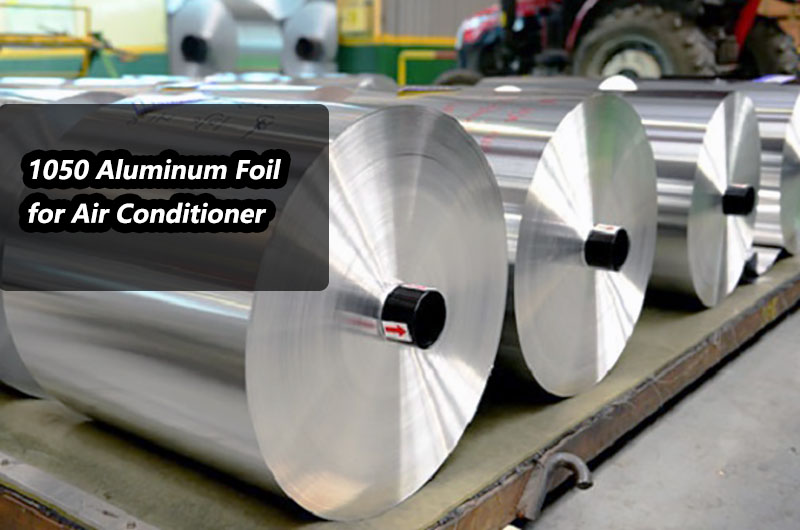

In the field of modern air conditioning technology, the importance of materials cannot be overstated. The pursuit of efficiency, sustainability and cost-effectiveness has led to the widespread use of aluminum foil, especially grade 1050 aluminum foil.

Learn about Aluminum Foil 1050

Aluminum Foil 1050 is a commercially pure aluminum alloy with high thermal conductivity and excellent corrosion resistance. It is a soft, malleable material with high reflectivity that makes it ideal for a variety of applications, including air conditioning.

Aluminum foil 1050 is a commonly used aluminum grade in the air conditioning industry. Air conditioning aluminum foil is a special material for manufacturing air conditioning heat exchanger fins. Aluminum foil for air conditioning fins is referred to as air conditioning aluminum foil.

Other ways of using aluminum foil in air conditioners

- Insulation: Aluminum foil is often used as reflective insulation. It helps reflect radiant heat, preventing it from being absorbed by surrounding materials. This is especially useful for insulating ducts or other components in HVAC systems.

- Ductwork: Aluminum foil is sometimes used to wrap or line ductwork. This helps prevent heat transfer or loss, ensuring conditioned air is efficiently delivered to the required areas.

- Air Duct Sealing: Aluminum foil tape is often used to seal joints and seams in air ducts. It provides a durable and heat-resistant seal that helps prevent air leaks and improves the overall efficiency of your HVAC system.

- Coil Protection: In some cases, aluminum foil can be used to protect HVAC coils from external elements or to increase heat exchange efficiency.

1050 air conditioner aluminum foil thermal conductivity

One of the main reasons why aluminum foil 1050 is popular in air conditioners is its excellent thermal conductivity. The ability to transfer heat efficiently is critical to the operation of your air conditioning system.

1050 aluminum foil is used as a heat exchanger in the evaporator and condenser coils, allowing rapid heat exchange between the refrigerant and air.

Corrosion resistance of 1050 air conditioner aluminum foil

Air conditioning systems operate in different environments and are inevitably exposed to moisture and chemicals. 1050 aluminum foil has excellent corrosion resistance, ensuring component longevity and reliability. This feature is especially important to prevent heat exchanger coil degradation over time.

1050 air conditioner aluminum foil is lightweight and formable

The lightweight properties of aluminum foil 1050 are advantageous in air conditioning applications. Its low density helps improve overall system efficiency and reduces load on compressors and other components. Additionally, aluminum foil is highly formable, allowing for complex designs in heat exchanger coils and other components.

Energy Efficiency Reflectivity

Reflectivity is a key factor in maintaining the energy efficiency of air conditioning systems. Aluminum foil 1050 has high reflectivity, which means it can reflect a large amount of radiant heat. This feature is used in the design of the insulating barrier to help minimize heat transfer and improve the overall performance of the system.

Easy to install and maintain

Another advantage of using aluminum foil 1050 in air conditioning applications is ease of installation. The material can be easily cut, shaped and installed, reducing installation time and costs. Additionally, the low maintenance requirements of aluminum foil contribute to the overall cost-effectiveness of your air conditioning system.

Recyclability and sustainability

In an era when sustainability is a top priority, the recyclability of Aluminum Foil 1050 is a significant advantage. The material is 100% recyclable and does not lose its inherent properties. The use of recycled aluminum in the manufacturing process contributes to the sustainability of the air conditioning industry, in line with global efforts to reduce environmental impact.

While aluminum foil 1050 offers many advantages, there are also challenges, such as its susceptibility to physical damage and its relatively low strength compared to some other alloys.

In summary, the use of 1050 aluminum foil in air conditioning systems demonstrates its superior properties, from thermal conductivity and corrosion resistance to recyclability and ease of installation.

As the air conditioning industry continues to evolve, the role of aluminum foil 1050 is likely to expand, helping to enable more efficient, sustainable and cost-effective HVAC solutions.

Informations you may be interested in:

- Which is better, hydrophilic aluminum foil or copper foil for air conditioners

- Hydrophilic aluminum foil vs non-hydrophilic aluminum foil

- Solutions to hydrophilic aluminum foil problems

- What is Hydrophilic Aluminum Foil?

- Hydrophilic aluminum foil performance indicators

- Factors Affecting the Hydrophilicity of Hydrophilic Aluminum Foil

- What components in air conditioning systems use aluminum foil?

- How is aluminum foil used for thermal insulation in air conditioning systems?

- Can aluminum foil be used in outdoor air conditioning units?

- Comprehensive analysis of air conditioning aluminum foil: classification and applications