- Anodized Aluminum

- Color Coated Aluminum

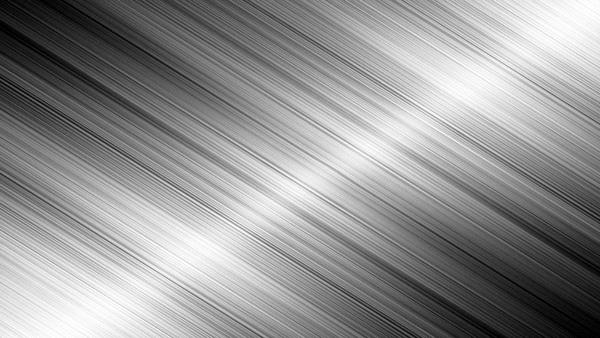

- Polished Aluminum

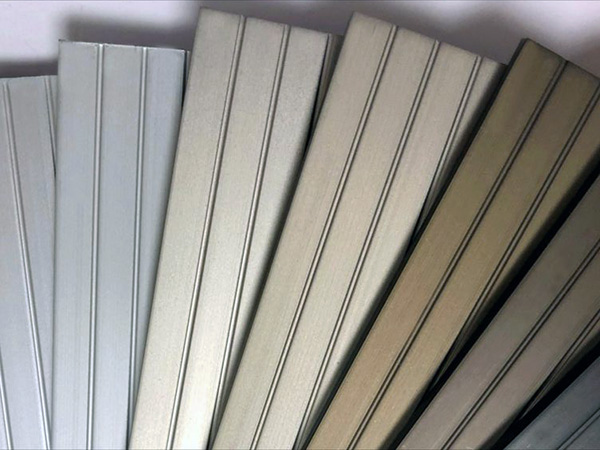

- Brushed Aluminum

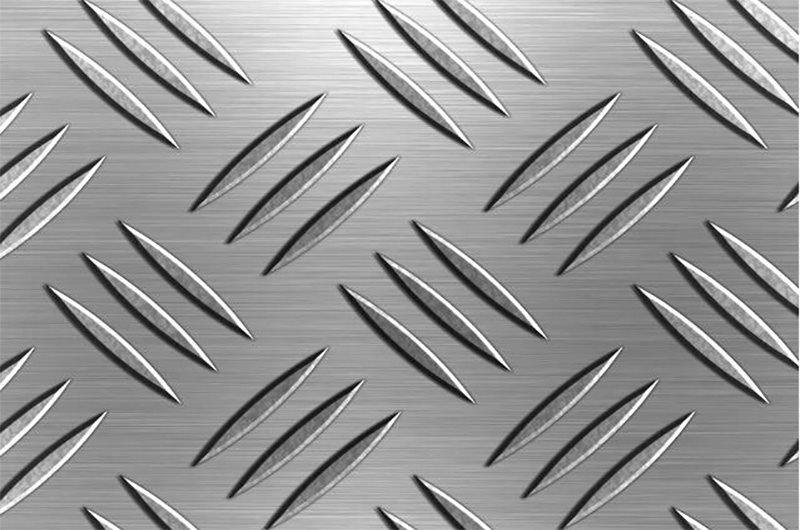

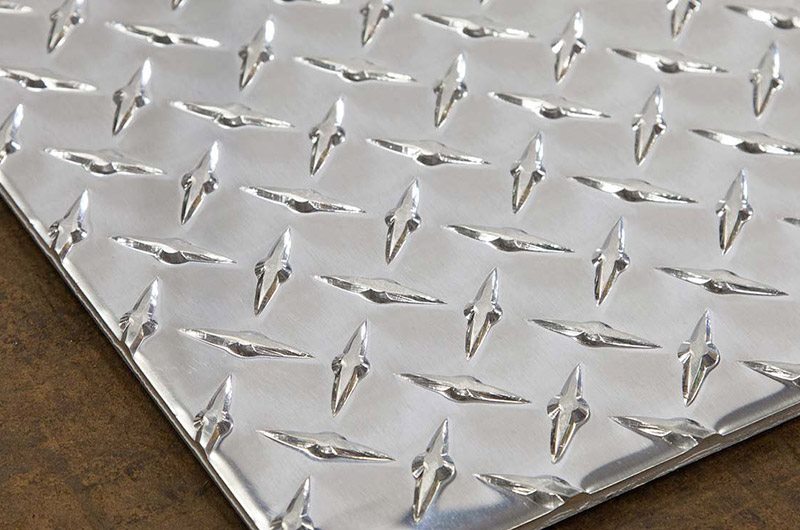

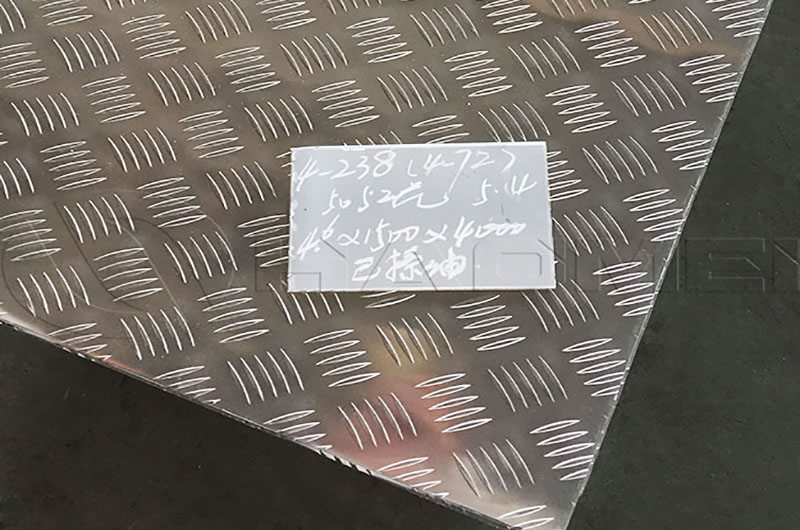

- Embossed Aluminum

- Powder Coating Aluminum

- Sandblasting

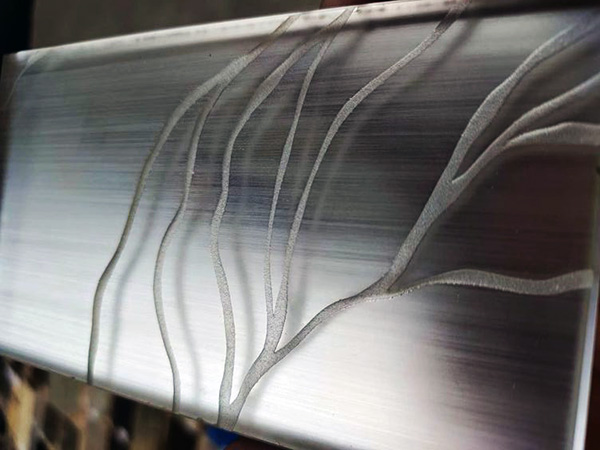

- Etching

- Electrophoresis

- Electroplating

Surface treatment was originally a surface protection technology that improved the corrosion resistance, wear resistance and other properties of the product by changing the mechanical, physical and chemical properties of the surface layer of the aluminum matrix material.

At present, various methods have been developed in aluminum surface processing technology to achieve excellent performance in aluminum corrosion resistance, appearance, texture, function and other aspects. like:

- Appearance: color, pattern, logo, gloss\line (3D, 2D)

- Texture: feel, roughness, longevity (quality), streamlined shape, etc.

- Function: hardening, anti-fingerprint, anti-scratch

Aluminum is a versatile material that can be treated in a variety of ways to achieve different finishes and properties. Here are each treatment method and a brief description of how to apply them to aluminum:

- Anodizing

- Painted

- Polishing

- Brushed

- Embossed

- Powder Coating

- Sandblasting

- Etching

- Electrophoresis (ed-electrophoresis Deposition)

- Electroplating

Anodized Aluminum

Anodizing is a common aluminum surface treatment that forms a protective oxide layer on the aluminum surface.

This oxide film has special properties such as protection, decoration, insulation, and wear resistance.

Process flow:

Single color, gradient color: polishing/sandblasting/drawing - degreasing - anodizing - neutralizing - dyeing - sealing - drying

Two colors:

- 1. Polishing/sandblasting/drawing - degreasing - masking - anodizing 1 - anodizing 2 - sealing - drying

- 2. Polishing/sandblasting/drawing - oil removal - anodizing 1 - laser engraving - anodizing 2 - sealing - drying

Features:

- 1. Increase strength

- 2. Realize any color except white.

- 3. Achieve nickel-free sealing to meet the nickel-free requirements of Europe, the United States and other countries.

Technical difficulties and key points for improvement:

The yield level of anodizing is related to the cost of the final product. The key to improving the oxidation yield lies in the appropriate dosage of oxidant, appropriate temperature and current density.

Color Coated Aluminum

Aluminum can be coated with various types of paints and coatings to achieve the desired color and finish.

Polished Aluminum

Aluminum can be polished to a high gloss and is often used for decorative or reflective applications.

For different polishing processes: rough polishing (basic polishing process), medium polishing (finishing process) and fine polishing (glazing process), choosing the appropriate polishing wheel can achieve the best polishing effect and improve polishing efficiency.

Technical features: Improve the dimensional accuracy or geometric shape accuracy of the workpiece, obtain a smooth surface or mirror gloss, and also eliminate the gloss.

Brushed Aluminum

Brushing is a surface treatment technique that gives aluminum a textured and brushed appearance and is commonly used in architectural and design applications.

According to the different textures after drawing, it can be divided into: straight grain drawing, random grain drawing, corrugated grain, and spiral grain.

Technical features:

Brushing treatment can give the metal surface a non-mirror-like metallic luster, and at the same time, brushing treatment can also eliminate subtle defects on the metal surface.

Embossed Aluminum

Embossing is another surface treatment method that can be used on aluminum materials. Embossing involves creating a raised or recessed pattern, design or texture on the aluminum surface. This process is often used for decorative and functional purposes, such as adding logos, patterns or tactile features to aluminum products.

Powder Coating Aluminum

Powder coating involves applying dry powder to an aluminum surface and then baking it to create a durable and attractive surface.

The powder coating is baked, leveled and solidified at high temperatures, turning into a final coating with different effects (different types of powder coating effects).

Process flow: loading-electrostatic dust removal-spraying-low temperature leveling-baking

advantage:

- 1. Rich colors, high gloss and matte optional;

- 2. Low cost, suitable for building furniture products and radiator shells, etc.;

- 3. High utilization rate, 100% utilization, environmentally friendly;

- 4. Strong ability to cover defects;

- 5. Can imitate wood grain effect.

Disadvantages: Currently it is rarely used in electronic products.

Sandblasting

Sandblasting is a surface treatment method that can be used on aluminum to create texture or remove existing finishes.

Technical features:

- 1. Achieve different reflections or matte.

- 2. It can clean the tiny burrs on the surface of the workpiece and make the surface of the workpiece smoother, eliminating the harm of burrs and improving the grade of the workpiece.

- 3. Remove the residual dirt left during pre-treatment, improve the smoothness of the workpiece, and make the workpiece reveal a uniform metal color, making the workpiece more beautiful and beautiful in appearance.

Etching

Etching can be used to create designs or patterns on aluminum surfaces by selectively removing material.

advantage:

- 1. Can carry out fine processing of metal surfaces.

- 2. Give special effects to metal surfaces.

Disadvantages: Most of the corrosive liquids (acid, alkali, etc.) used in etching are harmful to the environment.

Electrophoresis

Electrophoresis is a method of applying a protective or decorative coating to aluminum through an electrical process.

Electrophoresis is used for aluminum alloys, which can make the aluminum surface show various colors and maintain the metallic luster. It also enhances surface properties and has better anti-corrosion properties.

Process flow: pretreatment - electrophoresis - drying

advantage:

- 1. Rich colors;

- 2. No metal texture, can be used with sandblasting, polishing, brushing, etc.;

- 3. Processing in a liquid environment can achieve surface treatment of complex structures;

- 4. The technology is mature and can be mass produced.

Disadvantages: The ability to cover defects is average, and electrophoresis of die-casting parts requires high pre-processing requirements.

Electroplating

Electroplating can be used to deposit a layer of another metal, such as nickel or chromium, on the aluminum surface to enhance appearance and protection.

Electroplating is a technology that can prevent corrosion, improve wear resistance, conductivity, reflectivity and enhance aesthetics.

Process flow: pretreatment - cyanide-free alkali copper - cyanide-free cupronickel tin - chromium plating

advantage:

- 1. The coating has high gloss and high-quality metal appearance.

- 2. The cost is relatively low.

Disadvantages: poor environmental protection and greater risk of environmental pollution.

All of these methods can be used to modify the appearance, properties or functionality of aluminum surfaces, depending on the specific requirements of the application. The choice of treatment method depends on factors such as the desired surface preparation, corrosion resistance and other performance characteristics.

Informations you may be interested in: