- What is an Aluminum Strip for Battery Shell?

- Why is Aluminum Used for Battery Shells?

- What Role do these Strips Play in Battery Safety?

- Aluminum Strip for Battery Shell Specification

- Key Aluminum Strip for Battery Shell Introduction

- What Types of Batteries Use Aluminum Strips for Shells?

- How are these Aluminum Atrips Manufactured?

- Are Coatings Applied to the Strips for Battery Shells?

- Can Aluminum Strips for Battery Shells be Recycled?

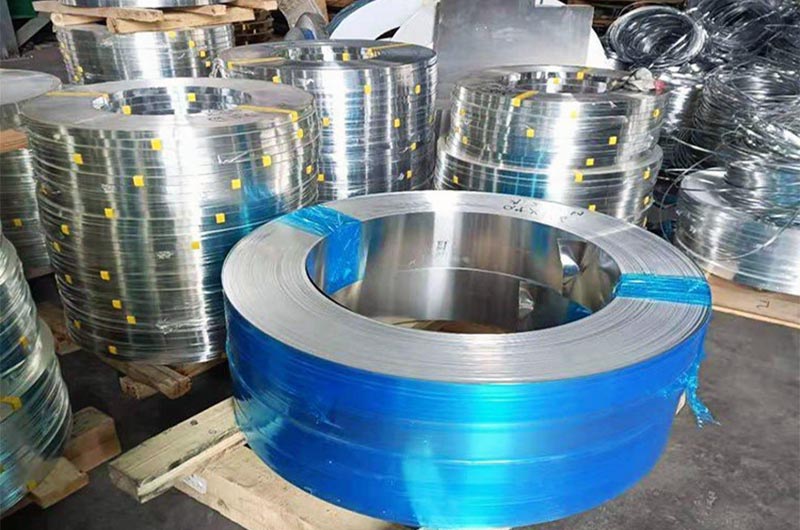

What is an Aluminum Strip for Battery Shell?

An aluminum strip for a battery shell is a thin, flat piece of aluminum used in the construction of battery casings or shells. It provides structural integrity, protection, and electrical insulation for batteries.

Aluminum strips for battery casings are usually made of high-purity aluminum, which has excellent electrical and thermal conductivity. This ensures that the battery can operate effectively and efficiently with minimal energy loss or heat build-up.

Why is Aluminum Used for Battery Shells?

Aluminum is chosen for battery shells due to its lightweight, corrosion resistance, and electrical conductivity. It helps protect batteries from external elements while ensuring efficient electrical performance.

Aluminum strip for battery case is a kind of aluminum strip specially used for the production of battery case. The battery case is an important part of the battery, providing a protective shell for the internal components of the battery and helping to ensure the safety and reliability of the battery.

Aluminum strips for battery cases may undergo a surface treatment process such as anodizing to improve their corrosion resistance, thereby improving their overall durability and service life. This is important because battery cases are often exposed to harsh environmental conditions and may experience corrosion or other forms of degradation over time.

Aluminum strips for aluminum battery cases have the characteristics of light weight, high strength, excellent electrical conductivity, corrosion resistance, and formability, and are ideal materials for manufacturing lightweight, high-performance batteries.

What Role do these Strips Play in Battery Safety?

Aluminum strips contribute to battery safety by enclosing and protecting the battery components, preventing external damage, and reducing the risk of short circuits.

Aluminum Strip for Battery Shell Specification

Common specifications of aluminum strips for aluminum battery cases include thickness, width and crimp diameter, etc. The specific specifications can be selected according to the size and requirements of the battery. The main alloys of aluminum strips for aluminum battery cases include 1xxx, 3xxx, 5xxx and 8xxx series, among which 3xxx and 5xxx series are the most commonly used, with good strength, formability and corrosion resistance.

- 1xxx series : pure aluminum strip, the common state is O (soft state). The specifications are generally 0.2-3.0mm in thickness and 100-1500mm in width. For example, 1050 aluminum strip, 1060 aluminum strip.

- 3xxx series : Mn is used as the alloy element, and the common states are H14, H16, H18, H19 and H24, etc. The specifications are generally 0.2-3.0mm in thickness and 100-1500mm in width. For example, 3003 aluminum strip, 3104 aluminum strip.

- 5xxx series : Mg is used as an alloying element, and the common states are H14, H16, H18, H19 and H24, etc. The specifications are generally 0.2-3.0mm in thickness and 100-1500mm in width. For example, 5052 aluminum strip, 5182 aluminum strip.

- 8xxx series : mainly other alloying elements, such as Li and Fe, etc., and the common states are O, H14, H16, H18 and H19, etc. The specifications are generally 0.2-3.0mm in thickness and 100-1500mm in width. For example, 8079 aluminum strip.

Key Aluminum Strip for Battery Shell Introduction

3004 Aluminum Strip for Battery Shell

3004 aluminum strip is an aluminum-manganese alloy used to manufacture battery casings with larger capacity and higher durability requirements.

- Advantages : higher strength, excellent corrosion resistance, better weldability and good formability.

- Application : It can be applied to lithium-ion batteries, power batteries, etc.

| Property | Value |

|---|---|

| Status | H19 |

| Hardness (HV) | 120 |

| Yield Strength (MPa) | 180 |

| Tensile Strength (MPa) | 240 |

| Elongation (%) | 20 |

5052 Aluminum Strip for Battery Shell

5052 aluminum strip is an aluminum-magnesium alloy commonly used in the manufacture of medium-sized battery casings.

- Advantages : Excellent corrosion resistance, oxidation resistance and strength, while easy to form and process, suitable for manufacturing some more complex battery casing structures.

- Application : It can be used in the manufacture of mobile phone batteries, laptop batteries, etc.

| Property | Value |

|---|---|

| Status | H32 |

| Hardness (HV) | 68 |

| Yield Strength (MPa) | 200 |

| Tensile Strength (MPa) | 260 |

| Elongation (%) | 12 |

5182 Aluminum Strip for Battery Shell

5182 aluminum strip is an aluminum-magnesium alloy, which is usually used to make large power battery casings.

- Advantages : high strength, good corrosion resistance and excellent formability, can withstand high temperature and high pressure environment, and also has good wear resistance.

- Application : It can be used in the manufacture of electric vehicle batteries, solar cells, etc.

| Property | Value |

|---|---|

| Status | H111 |

| Hardness (HV) | 45 |

| Yield Strength (MPa) | 260 |

| Tensile Strength (MPa) | 310 |

| Elongation (%) | 10 |

6061 Aluminum Strip for Battery Shell

6061 aluminum strip is an aluminum-magnesium-silicon alloy, which is usually used to manufacture high-performance power battery casings.

Advantages : high strength, excellent corrosion resistance and good weldability, but also has excellent mechanical properties, such as strength, plasticity and toughness.

When selecting an aluminum strip for an aluminum battery case, it is necessary to determine its performance indicators, such as strength, formability, electrical conductivity, corrosion resistance, etc., according to the requirements of the battery and specific application scenarios, and choose an aluminum strip manufacturer that meets the requirements of standards and specifications , to ensure the stability of product quality and performance.

| Property | Value |

|---|---|

| Status | T6 |

| Hardness (HV) | 95 |

| Yield Strength (MPa) | 276 |

| Tensile Strength (MPa) | 310 |

| Elongation (%) | 12 |

What Types of Batteries Use Aluminum Strips for Shells?

Aluminum strips are used in various types of batteries, including lithium-ion batteries, alkaline batteries, and other rechargeable battery technologies.

Aluminum strip for aluminum battery casing is an aluminum alloy strip used to manufacture battery casings. It is mainly used in battery manufacturing industries such as lithium-ion batteries, nickel-metal hydride batteries, nickel-cadmium batteries, and lead-acid batteries.

- 1050 aluminum strip : suitable for the manufacture of battery shells with low voltage and low energy density such as disposable batteries and small dry batteries.

- 1060 aluminum strip : suitable for applications requiring high sealing, such as disposable batteries and battery packaging.

- 3003 aluminum strip : It is suitable for the manufacture of battery shells with medium and low power and medium energy density such as charging treasures and power batteries.

- 3104 aluminum strip : suitable for the manufacture of battery casings with medium to high power and medium energy density such as lithium-ion batteries and polymer lithium batteries.

- 5052 aluminum strip : suitable for the manufacture of high-power, high-energy-density battery cases such as automotive power batteries and industrial energy storage batteries.

- 5182 aluminum strip : suitable for the manufacture of high-power, high-energy-density battery cases such as automotive power batteries and new energy vehicle energy storage batteries.

- 8079 aluminum strip : It is suitable for the manufacture of battery cases that require high sealing and tearability, such as flexible packaging lithium-ion batteries and polymer lithium batteries.

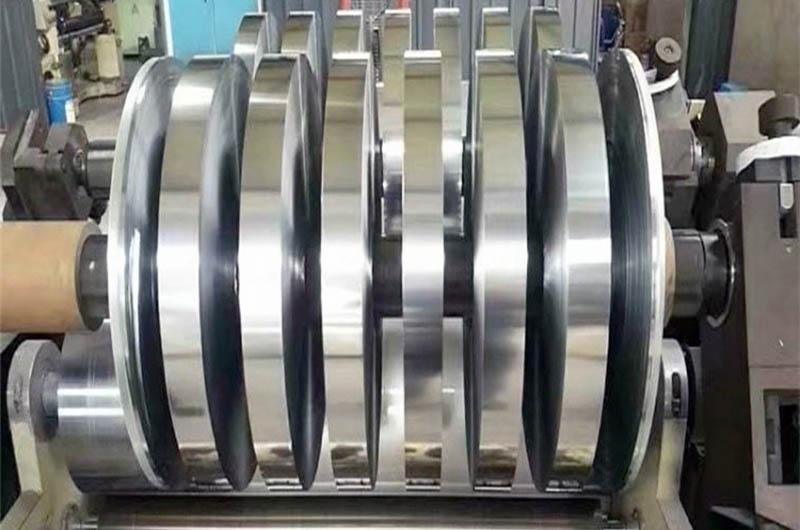

How are these Aluminum Atrips Manufactured?

The strips are typically produced through processes like hot rolling or cold rolling, followed by surface treatment and cutting to the required dimensions.

Are Coatings Applied to the Strips for Battery Shells?

Yes, coatings like lacquers or paints can be applied to provide additional protection against corrosion and enhance electrical insulation.

Can Aluminum Strips for Battery Shells be Recycled?

Yes, aluminum is highly recyclable, and using recycled aluminum for battery shell strips contributes to sustainable manufacturing practices.