- What is Aerospace Grade Aluminum?

- Which Aluminum Plate is Used in Aircraft?

- Typical Aerospace Aluminum Alloys Chemical Composition

- Typical Aerospace Aluminum Alloys Mechanical Properties

- Aerospace Aluminum for Aircraft Structures

- Haomei Aluminum Aerospace Aluminum Grades for Sale

- How Strong is Aerospace Aluminum?

- How Thick is an Aircraft Aluminum Sheet?

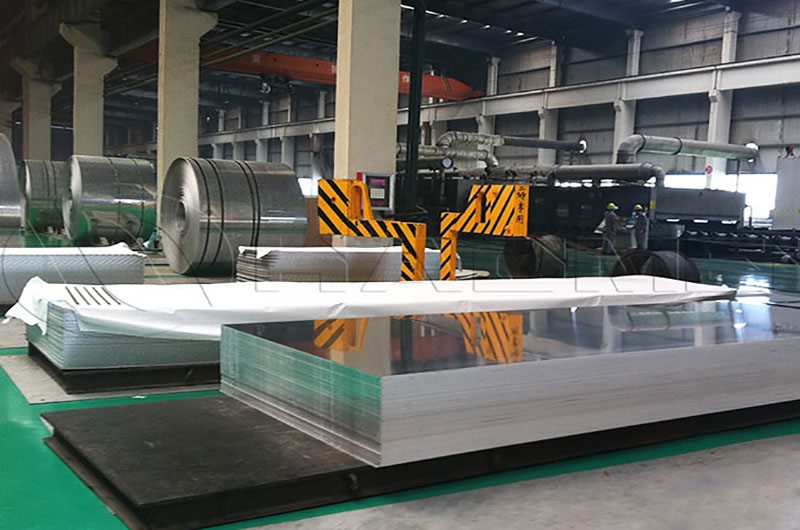

- Aerospace Aluminum Supplier

What is Aerospace Grade Aluminum?

Aerospace aluminum plate and sheet are specialized types of aluminum alloys that are used in the aerospace industry due to their high strength-to-weight ratio, corrosion resistance, and other desirable properties. These are typically made from high strength aluminum alloys such as 2024-T3, 7075-T6 and 6061-T6.

The aerospace industry uses aluminum sheet and sheet in a variety of applications, including aircraft fuselage and wing skins, structural components, and engine components. These materials are often subjected to extremes of temperature, pressure and other environmental factors, so they must be able to withstand harsh conditions while remaining lightweight and durable.

In addition to mechanical properties, aviation aluminum sheets and sheets are often subjected to special surface treatments such as anodizing or painting to further enhance their corrosion resistance and other properties.

Which Aluminum Plate is Used in Aircraft?

Aluminum is Used in Aaircraft mainly includes 2xxx series, 5xxx series and 7xxx series, and different alloy series have different characteristics and applications.

1. 2000 series aluminum alloys are commonly used in wing and fuselage structures.

- 2024 Aircraft Aerospace Grade Aluminum Plate

- 2219 Aircraft Aerospace Grade Aluminum Plate

- 2017 Aircraft Aerospace Grade Aluminum Plate

- 2618A Aircraft Aerospace Grade Aluminum Plate

- 2014/2014A Aircraft Aerospace Grade Aluminum Plate

- 2324 T39 Aircraft Aerospace Grade Aluminum Plate

- 2124 Aircraft Aerospace Grade Aluminum Plate

- 2A70 Aircraft Aerospace Grade Aluminum Plate

- 2A16 Aircraft Aerospace Grade Aluminum Plate

- 2A14 Aircraft Aerospace Grade Aluminum Plate

- 2A12 Aircraft Aerospace Grade Aluminum Plate

- 2A11 Aircraft Aerospace Grade Aluminum Plate

2. 5000 series aluminum alloys are used for fuel tanks and hydraulic systems.

- 5A03 Aircraft Aerospace Grade Aluminum Plate

- 5251 Aircraft Aerospace Grade Aluminum Plate

- 5052 Aircraft Aerospace Grade Aluminum Plate

- 5083 Aircraft Aerospace Grade Aluminum Plate

- 5454 Aircraft Aerospace Grade Aluminum Plate

- 5086 Aircraft Aerospace Grade Aluminum Plate

- 5456 Aircraft Aerospace Grade Aluminum Plate

- 5A02 Aircraft Aerospace Grade Aluminum Plate

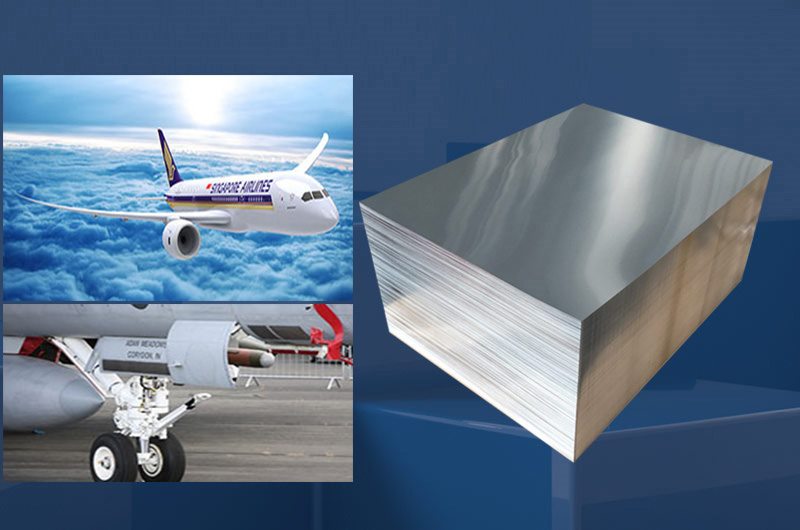

3. 7075 aluminum alloy is often used in aircraft landing gear and other components that require high strength.

- 7075 Aircraft Aerospace Grade Aluminum Plate

- 7055 Aircraft Aerospace Grade Aluminum Plate

- 7050 Aircraft Aerospace Grade Aluminum Plate

- 7475 Aircraft Aerospace Grade Aluminum Plate

- 7150 Aircraft Aerospace Grade Aluminum Plate

- 7085 Aircraft Aerospace Grade Aluminum Plate

- 7010 Aircraft Aerospace Grade Aluminum Plate

- 7B04 Aircraft Aerospace Grade Aluminum Plate

- 7A33 Aircraft Aerospace Grade Aluminum Plate

- 7A09 Aircraft Aerospace Grade Aluminum Plate

- 7A04 Aircraft Aerospace Grade Aluminum Plate

- 7014 Aircraft Aerospace Grade Aluminum Plate

- 7049 Aircraft Aerospace Grade Aluminum Plate

- 7150 Aircraft Aerospace Grade Aluminum Plate

- 7178 Aircraft Aerospace Grade Aluminum Plate

Due to their low density and good strength and rigidity, aluminum alloys are one of the most commonly used materials in the aerospace industry.

| Alloy | Applications |

|---|---|

| 7050, 7475, 7099 | Wing Ribs |

| 7050, 7475, 7099 | Wing Spars |

| 7050 | Leading Edge Ribs |

| 7050, 7475 | Wing Attach Structure |

| 7050 | Trailing Edge Ribs |

| 2024, 7075, 7475 | Wing Skins |

| 2024, 7075, 7075 | Fuselage Frames |

| 7050 | Bulkheads |

| 2024, 7075 | Tailcone Components |

| 7050 | Cargo Floor Beams |

| 2024, 7075 | Door Components |

| 7050, 7099 | Wing to Body Fairing Components |

| 2124, 2219 | Engine Support Structure |

| 7050 | Baggage Bin Structure |

| 6061 | Seat Legs |

| 2024, 7050, 7075, 7475 | Vertical Tail Ribs and Spars |

| 2024, 7050, 7075 | Horizontal Tail Fittings |

| 2024, 6061 | Leading Edge Skins |

| 7075 | Fuselage Stringer |

| 2024, 7075, 7075 | Fuselage Frames |

| 2024, 7075 | Fuselage Brackets |

| 2024 | Fuselage Skins |

| 2024, 7075 | Door Components |

| 2219 | Engine Inlet Lip Skins |

| 2024 | Engine Cowl Skins |

| 2024, 7075 | Seat Pans |

Typical Aerospace Aluminum Alloys Chemical Composition

6061 7075 2024 Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others Each | Others Total | Al. Min. |

| 6061 | 0.40- 0.8 | 0.7 | 0.15- 0.40 | 0.15 | 0.8- 1.2 | 0.04- 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1- 2.9 | 0.18- 0.28 | 5.1- 6.1 | 0.20 | 0.05 | 0.15 | Rem. |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.9 | 1.2- 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

Typical Aerospace Aluminum Alloys Mechanical Properties

6061 7075 2024 Mechanical Properties

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation (%) for the following gauge ranges: | Tensile Strength | Yield Strength | Elongation (%) for the following gauge ranges: | ||

| (ksi) | (ksi) | 0.010-0.050 | 0.051-.125 | (MPa) | (MPa) | 0.25-1.25mm | 1.26-3.0mm | ||

| 6061 | O | 18 | 8 | 25 | 26 | 124.1 | 55.2 | 25 | 26 |

| T4 | 35 | 21 | 22 | 24 | 241.3 | 144.8 | 22 | 24 | |

| T6 | 45 | 40 | 12 | 17 | 310.3 | 275.8 | 12 | 17 | |

| 7075 | O | 33 | 15 | 16 | 18 | 227.5 | 103.4 | 16 | 18 |

| T6 | 83 | 73 | 11 | 12 | 572.3 | 503.3 | 11 | 12 | |

| 2024 | O | 27 | 11 | 18 | 20 | 186.2 | 75.8 | 18 | 20 |

| T3 | 70 | 50 | 16 | 18 | 482.6 | 344.7 | 16 | 18 | |

| T4 | 68 | 47 | 20 | 19 | 468.8 | 324.1 | 20 | 19 | |

Aerospace Aluminum for Aircraft Structures

2024-T4 Aluminum for Fuselage Skin

The 2024-T4 aluminum alloy used for the skin of the fuselage has the characteristics of high strength, good formability, excellent shape and surface quality, etc.

7150-T7751 7055-T7751 2024 Aerospace Aluminum for Wing Panel

Aluminum alloys such as 7150-T7751, 7055-T7751, and 2024-HDT have the characteristics of high strength, high toughness, corrosion resistance, and high damage tolerance, and are widely used in structural components such as wing panels and rib webs.

7150-T7751, 7055-T7751, 2024-HDT and other aluminum alloys have a width of 2500mm and a length of 10000mm

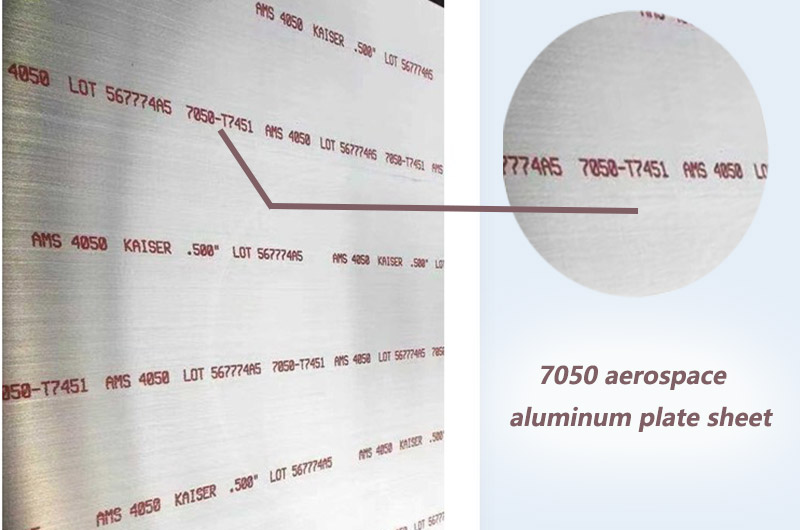

7050-T7451 Aerospace Aluminum Alloy for Fuselage reinforcement frame

The 7050-T7451 aluminum alloy thick plate used for fuselage reinforcement frame, fuselage keel, fuselage bulkhead, etc. has the characteristics of high strength, high toughness, corrosion resistance, etc., and is the most widely used aluminum alloy in the aviation field.

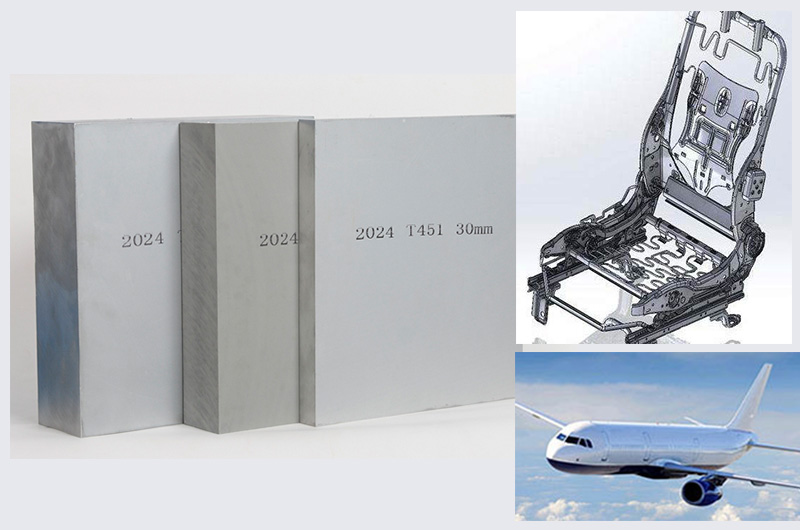

2024-T3511 Aerospace Aluminum for Air seat

The 7055-T76511 and 2024-T3511 aluminum alloy strips used for aviation seats have the characteristics of high strength, good toughness, uniform color after anodizing, and no color difference.

7021-T6 Aerospace Aluminum for Air Container

7021-T6 and other aluminum alloy sheets used in air containers have the characteristics of ultra-wide width, high dimensional accuracy, good shape and surface quality, etc.

Haomei Aluminum Aerospace Aluminum Grades for Sale

Some common examples of aerospace-grade aluminum alloys include 2024-T3, 6061-T6, and 7075-T6. These alloys are used in a variety of aerospace applications, including the construction of aircraft frames, wings, and other structural components, and the manufacture of spacecraft and rockets.

2024-T3 Aerospace Aluminum Plate Sheet

T3 temper means solution heat treated followed by artificial aging, 2024-T3 Aluminum has excellent fatigue resistance and is easy to process, making it a popular choice for aircraft manufacturing.

2024-T3 Aerospace Aluminum Plate Sheet is a high-strength aluminum alloy commonly used in aircraft structures, including wings, fuselages and other components requiring strength and durability.

6061-T6 Aerospace Aluminum Plate Sheet

T6 tempering means solution heat treatment followed by artificial aging. 6061 T6 Aluminum has good corrosion resistance and is relatively easy to machine and weld.

6061 T6 Aerospace Aluminum This is a versatile aluminum alloy widely used in aircraft applications including structural components, landing gear and hydraulic systems.

7075-T6 Aerospace Aluminum Plate Sheet

T6 tempering refers to solution heat treatment followed by artificial aging treatment. 7075 T6 Aluminum has excellent fatigue strength, strength to weight ratio and good machinability.

7075 T6 Aerospace Aluminum is a high strength aluminum alloy commonly used in aerospace applications such as aircraft fuselage frames, wing skins and other highly stressed components.

5052-H32 Aerospace Aluminum Plate Sheet

5052 h32 is a marine-grade aluminum alloy commonly used in aircraft fuel tanks and other components that come into contact with corrosive materials.

It has good corrosion resistance and is relatively light.

Due to their special composition and manufacturing process, aerospace-grade aluminum alloys are generally more expensive than other types of aluminum alloys, but they are critical to ensuring the safety and reliability of aerospace equipment.

How Strong is Aerospace Aluminum?

Aerospace aluminum alloys are engineered to have high strength-to-weight ratios, making them ideal for aircraft and spacecraft structures. The strength of aerospace aluminum depends on the specific alloy and the manufacturing process used.

The strength of commonly used aviation aluminum alloys:

| Grade | 7075 | 2024 |

|---|---|---|

| State | T6 | T3 |

| Tensile Strength(MPa) | 430~450 | 434 MPa |

| Yield Strength(MPa) | 280~310 | 324 MPa |

| Application | Structural components | Machine skin, wing and fuselage structure |

Overall, aerospace aluminum alloys are known for their high strength, durability, and corrosion resistance, making them ideal for a variety of aerospace applications.

How Thick is an Aircraft Aluminum Sheet?

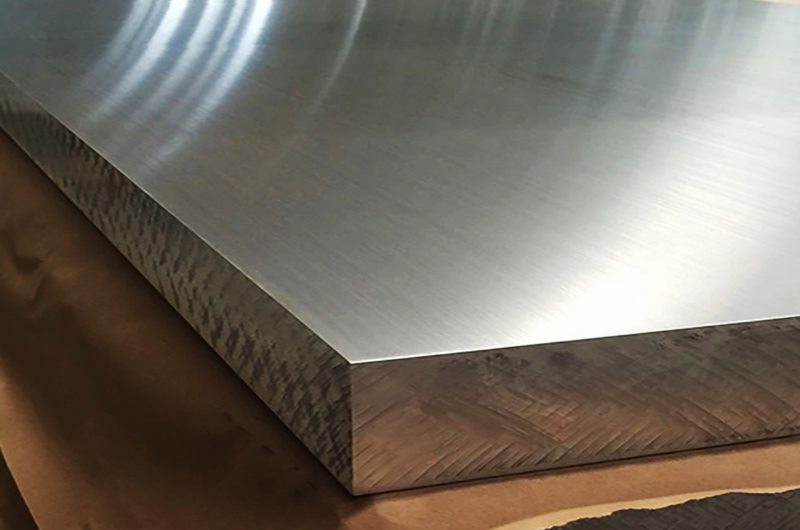

The thickness of aircraft aluminum sheet can vary depending on the specific application and requirements. Generally, aircraft aluminum sheet thicknesses range from 0.008 inches (0.20 mm) to several inches, depending on the intended use.

- Thin aluminum sheet between 0.008" (0.20mm) - 0.125" (3.18mm) can be used for aircraft skin panels.

- Thicker aluminum sheets between 0.25" (6.35mm) - 3" (76.2mm) can be used for spars or other structural components.

The thickness of the aluminum sheet used in a particular aircraft component is usually determined by engineering calculations and considerations, taking into account factors such as expected loads and stresses, the weight of the component, and required strength and stiffness.

Aerospace Aluminum Supplier

In order to ensure the quality of aviation aluminum panels, Haomei Aluminum follows relevant standards and specifications, such as AMS specifications and AS9100 certification.

During the production process, the manufacturer adopts strict quality control measures to monitor and test the chemical composition, physical properties, mechanical properties and surface quality indicators to ensure that the quality of aviation aluminum panels meets the requirements. In addition, aviation aluminum panels are also tested for non-destructive testing to ensure that there are no internal defects.