- What is Aluminum Tread Plate?

- What are the Benefits of Using Aluminum Tread Plate?

- Aluminum Tread Plate Sheet Specifications

- Aluminum Tread Plate Sheet Classification

- What Grade is Aluminum Tread Plate?

- What are the Common Applications of Aluminum Tread Plate?

- Aluminum Tread Plate Supplier

- Frequently Asked Questions (FAQ) about Aluminum Tread Plate

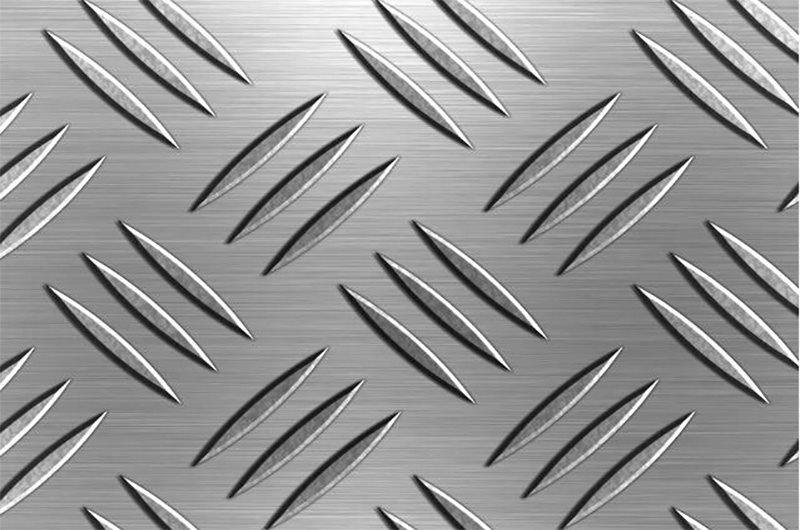

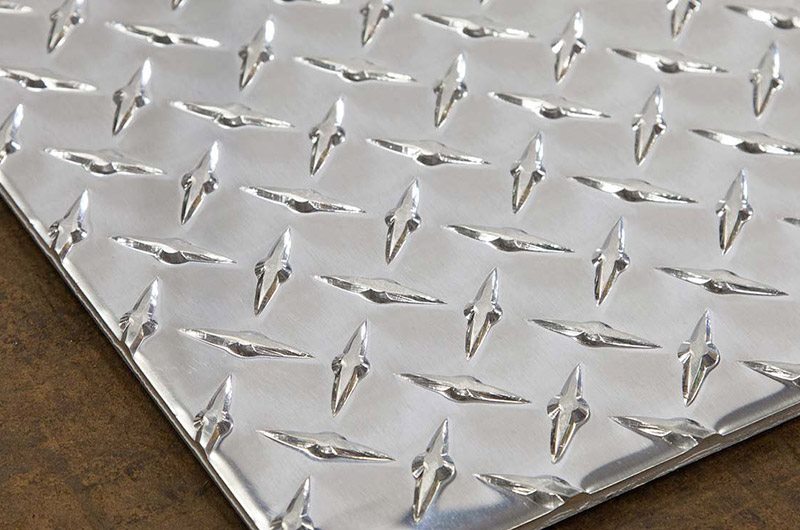

What is Aluminum Tread Plate?

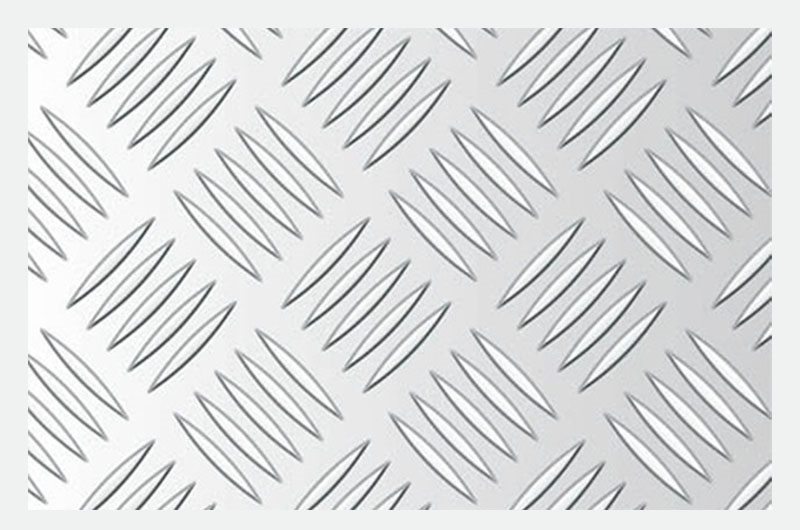

Aluminum tread plate, also known as aluminum checker plate or diamond plate, is an aluminum plate with raised diamond-shaped or linear patterns on one side. The pattern provides slip resistance and traction, making it ideal for use in industrial settings or where there is a risk of slipping, such as stairs, ramps and walkways.

Aluminum pedals are typically made from 1000, 3000 or 5000 series aluminum alloys known for their corrosion resistance, durability and strength-to-weight ratio. Sheets range in thickness from 1.5mm to 6mm, with the most common thicknesses being 2mm, 3mm and 4mm.

Aluminum Tread Plates are commonly used in the automotive, construction and transportation industries and also for decorative purposes. It is easy to maintain, lightweight and has a long service life, making it a cost-effective solution for a wide range of applications.

What are the Benefits of Using Aluminum Tread Plate?

- Excellent Corrosion Resistance

- High Strength-to-weight Ratio

- Aesthetic Appeal

- Easy to Clean and Maintain

- Anti-slip Surface

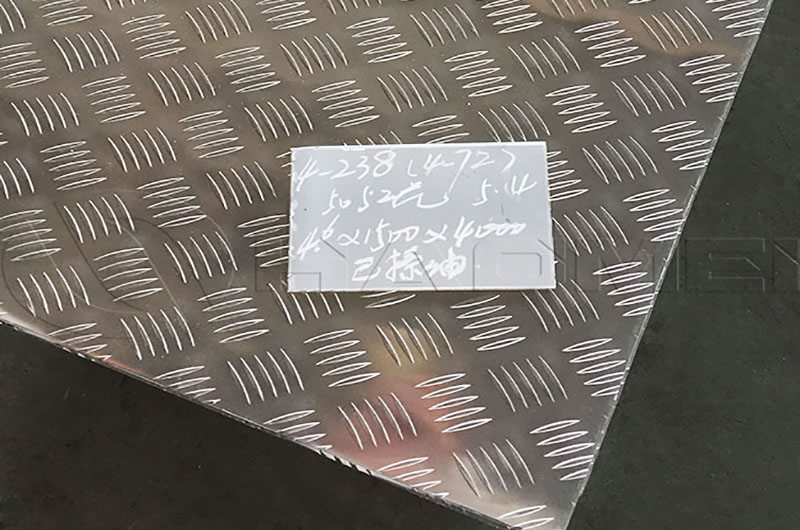

Aluminum Tread Plate Sheet Specifications

Aluminum tread plate sheet thickness, size and grade, pattern, color, surface treatment, etc. can be customized according to specific needs. Here are some common options :

- Thickness : Common thicknesses are 0.125 inches (3.175 mm), 0.188 inches (4.775 mm) and 0.25 inches (6.35 mm), etc. Other thicknesses can also be customized.

- Size and Grade : Common sizes are 4 feet x 8 feet (1219mm x 2438mm), 4 feet x 10 feet (1219mm x 3048mm), etc. Other sizes can also be customized. The grades are usually 3003, 5052 and 6061 etc.

- Pattern : The common patterns are diamond shape and linear shape, and other patterns can also be customized.

- Color : Aluminum panels can be coated or anodized for additional color options. Common colors are white, black, red, blue, etc. Other colors can also be customized.

- Surface treatment : The surface of the aluminum plate can be coated, anodized, frosted, etc. to increase its appearance and durability.

Aluminum Tread Plate Sheet Classification

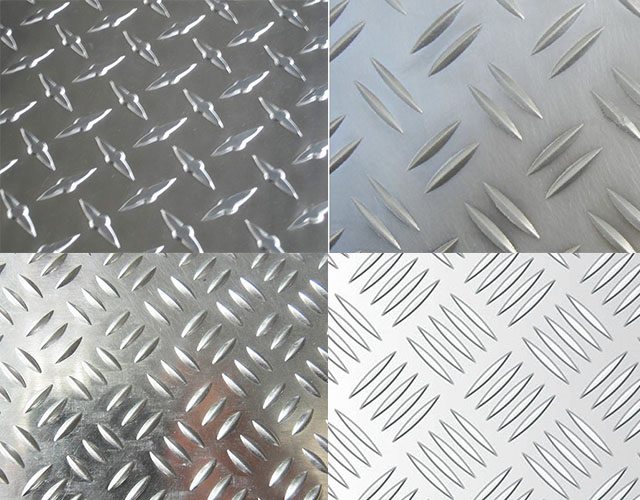

Classified by Pattern Type

| Pattern Type | Alloy |

|---|---|

| 2 Bar Aluminum Tread Plate | 1050A, 3003 |

| 3 Bar Aluminum Tread Plate | 1100, 3003, 5052 |

| 5 Bar Aluminum Tread Plate | 1100, 3003, 5052 |

| Aluminum Diamond Plate Plate | 1050, 3003 |

2/3/5 Bar Aluminum Tread Plate

- Function: Increase surface friction, improve slip resistance

- Application: Truck Bed, Flooring, Platforms, Ships, Industrial Equipment, Building Decoration

Aluminum Diamond Plate Plate

- Function: Increase surface friction, decorative, improve aesthetic appeal

- Application: Flooring, Steps, Platforms, Industrial Equipment, Building Decoration

Surface Treatment Classification

| Surface Treatment | Common Alloy Number |

|---|---|

| Mill Finish Aluminum Tread Plate | 1050A, 1060, 1100 |

| Anodized Aluminum Tread Plate | 3003, 5052, 6061 |

| Coated Aluminum Tread Plate | 3003, 5052, 6061 |

| Electrophoretic Coated Aluminum Tread Plate | 3003, 5052, 6061 |

Mill Finish Aluminum Tread Plate

- Characteristics and Functions: Natural texture of aluminum, easy to process and weld

- Application: Decoration, construction

- Specific Examples of Use: Roof, wall, ceiling, etc.

Anodized Aluminum Tread Plate

- Characteristics and Functions: Increased surface hardness and corrosion resistance, and color diversity

- Application: Decoration, construction

- Specific Examples of Use: Interior decoration, curtain wall, ceiling, etc.

Coated Aluminum Tread Plate

- Characteristics and Functions: Achieving various colors and effects, such as mirror finish, spray coating, powder coating, etc.

- Application: Indoor/outdoor decoration, transportation, home appliances

- Specific Examples of Use: Interior wall decoration, exterior curtain wall, TV back panel, auto parts, manufacturing industry, etc.

Electrophoretic Coated Aluminum Tread Plate

- Characteristics and Functions: Uniform, delicate, and corrosion-resistant, widely used for high-end product surface treatment

- Application: Indoor/outdoor decoration, electronic products

- Specific Examples of Use: Mobile phone shell, laptop shell, digital camera shell, high-end furniture surface, interior decoration, etc.

What Grade is Aluminum Tread Plate?

3003 Aluminum Tread Plate

3003 Aluminum This is the most common grade used for aluminum checkered plates. It is a general purpose alloy with good machinability and weldability.

- Alloy state : O, H12, H14, H16, H18, H22, H24, H26, H28, H32, H34, H36, H38.

- Unique advantages : excellent corrosion resistance and formability, suitable for processing into various complex shapes and structures.

- Applications : Indoor and outdoor decoration, vehicles, electrical appliances, manufacturing and other fields.

- Specific application examples : decorative walls, indoor screens, billboards, traffic signs, body panels, tanks, kitchen utensils, etc.

4017 Aluminum Tread Plate

The 4017 aluminum tread plate has good weldability, easy processing and manufacturing, and can effectively improve the carrying capacity and service life of the container.

- Alloy state : H16, H18.

- Unique advantages : high strength, good corrosion resistance, smooth surface, good weldability.

- Applications : light commercial vehicles, containers, construction and other fields.

- Specific application examples : truck bodies, cargo boxes, containers, etc.

5052 Aluminum Tread Plate

5052 has higher strength and better corrosion resistance than 3003 aluminum checkered plate. It is commonly used in marine applications and other environments where high resistance to salt water corrosion is required.

- Alloy state : O, H32, H34, H36, H38.

- Unique advantages : high strength, strong corrosion resistance, easy welding and processing, smooth surface.

- Applications : construction, transportation, electronic products and other fields.

- Specific application examples : curtain walls, subway cars, ships, auto parts, digital camera casings, etc.

What are the Common Applications of Aluminum Tread Plate?

Aluminum tread plate is used in a wide range of applications, including flooring, toolboxes, trailers, stair treads, vehicle running boards, decorative wall panels, and more. It's commonly used in areas where slip resistance and durability are important.

The patterned aluminum plate is made of high-quality aluminum alloys such as 3003, 5052, and 6061, and is widely used in various industries such as transportation, construction, decoration, machinery, and equipment manufacturing. Here are some common applications of patterned aluminum sheet :

- Truck and Trailer Flooring : Aluminum checker panels are commonly used for truck and trailer flooring due to their strength, durability, and slip resistance.

- Stair Treads : The raised pattern on the surface of aluminum treads makes them a popular choice for stair treads, especially in high traffic areas.

- Decorative Applications : The unique pattern of patterned aluminum sheet makes it a popular choice for decorative applications such as wall panels and backsplashes.

- Industrial Equipment : Aluminum treads are used in the manufacture of industrial equipment such as machine tools, workstations and platforms.

Patterned aluminum sheets are available in a variety of thicknesses, sizes and grades to suit different applications. It can also be customized with different patterns, colors and finishes.

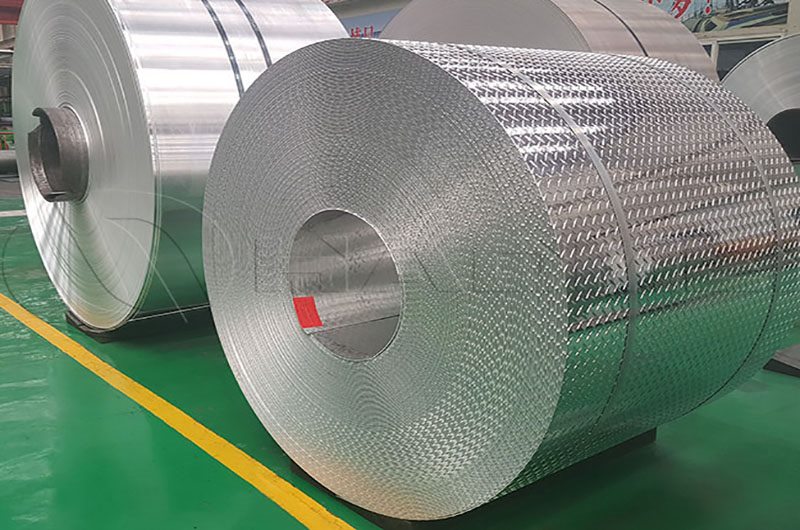

Aluminum Tread Plate Supplier

- Surface finish : The surface of the pedal is smooth and flat, without scratches, dents, cracks and other defects.

- Thickness and Size : The thickness and size of the tread is appropriate for the intended application. Thicker treads are generally stronger and more durable, while larger treads provide more surface area for better traction.

- Manufacturing Process : Treads are manufactured using high-quality equipment and workmanship, ensuring consistency and accuracy in pattern, thickness and surface finish.

- Pattern Design : Treads are patterned or designed to meet customer application requirements and provide good traction while being easy to clean and resistant to wear.

Frequently Asked Questions (FAQ) about Aluminum Tread Plate

How is Aluminum Tread Plate Manufactured?

Aluminum tread plate is typically made by passing flat aluminum sheets through a rolling mill with embossed rollers. This process creates the raised patterns on the surface.

Can Aluminum Tread Plate be used Outdoors?

Yes, aluminum tread plate is suitable for outdoor applications due to its excellent corrosion resistance. However, the specific alloy and finish should be chosen based on the environmental conditions it will be exposed to.

Is Tread Plate the same as Diamond Plate?

Yes, "Tread Plate" and "Diamond Plate" refer to the same type of aluminum sheet that has a raised diamond or other pattern on its surface. The terms are often used interchangeably in the industry, although "Tread Plate" is more commonly used in the UK, while "Diamond Plate" is more commonly used in the US.

How to Cut Aluminum Tread Plate?

- Handheld Scissors : Handheld scissors can be used to cut aluminum treads up to 0.125" (3.2mm) thick. This method is great for making rough cuts or cutting simple shapes.

- Jigsaw : A jigsaw with a fine-toothed blade can be used to cut aluminum treads approximately 0.25 inches (6.4 mm) thick. This method produces a more precise cut than handheld scissors, but may require some sanding or filing to achieve a smooth finish.

- Circular Saw : A circular saw with a carbide blade can be used to cut thick aluminum treads up to about 0.5 inches (12.7 mm) thick. This method produces a straight, clean cut, but the blade can wear down quickly and generate a lot of heat.

- Plasma cutting machine : Plasma cutting machine can be used to cut patterned aluminum plate of any thickness. This method produces very precise cuts and doesn't generate a lot of heat, but it requires specialized tools and can be more expensive than other cutting methods.

Whichever method you choose, you must wear proper safety gear, including eye and ear protection, and take care to avoid damaging the aluminum pedals during the cutting process.

How to Clean Aluminum Tread Plate?

- Use a soft brush or vacuum to remove any loose dirt or debris from the surface of the aluminum pedal.

- Mix a solution of warm water and mild detergent or detergent. Dish soap or laundry detergent can be used for this purpose.

- Dip a soft sponge or cloth into the cleaning solution and wring out excess water.

- Gently scrub the surface of the aluminum pedals with a sponge or cloth, using circular motions. Be sure to pay special attention to any areas with stubborn stains or dirt.

- Rinse the surface of the aluminum treads thoroughly with clean water to remove any remaining soap residue.

- Use a clean dry cloth or towel to dry the surface of the aluminum pedals.

- For more stubborn stains or discoloration, you may need to use a specialized aluminum cleaner or polish. Always follow the directions carefully and test the product on a small, inconspicuous area of the pedal before using the product on an entire surface.