- Why is Aluminum Used for Tank Truck Construction?

- What are the Advantages of using Aluminum Plates Over Steel in Tank Trucks?

- Tank Truck Aluminum Plate Specifications

- Typical Tank Car Aluminum Plate Introduction

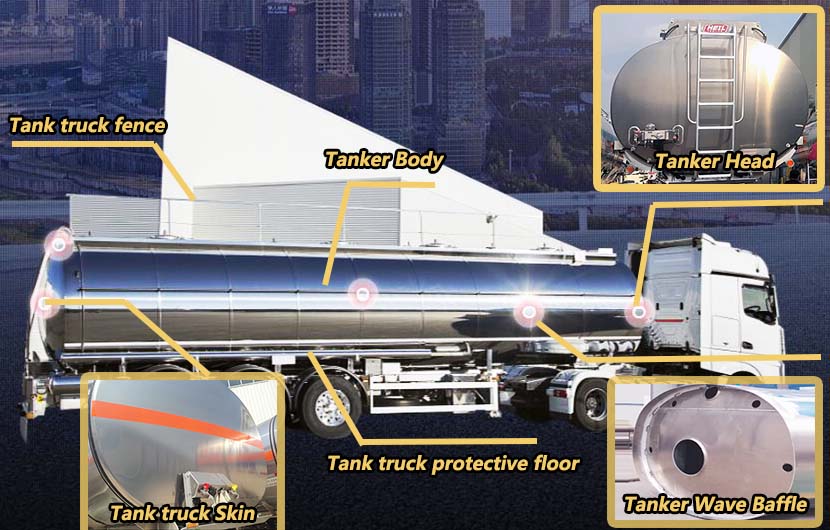

- Which structures of tank trucks use aluminum plates?

- Chemical composition of tank truck aluminum plate alloy

- Mechanical properties of tank truck aluminum plates

- Which tank trucks use aluminum plates?

- What Thickness Aluminum for Fuel Tank

- Frequently Asked Questions (FAQs) about Aluminum Plates for Tank Trucks

- Haomei Aluminum Tank Car Aluminum Plate Quality

- Other aluminum material information for tank trucks

Tank car aluminum plate refers to the aluminum alloy plate used to manufacture various types of tank cars. They are usually made of high-strength aluminum alloys for high pressure and corrosion resistance. Aluminum tanker plates are widely used in vehicles for transporting liquid or gas, such as petrochemical industry, food processing industry, pharmaceutical industry, etc.

Why is Aluminum Used for Tank Truck Construction?

Aluminum is chosen for tank truck construction due to its lightweight nature, corrosion resistance, and strength-to-weight ratio. It helps reduce the overall weight of the truck, increasing fuel efficiency and payload capacity.

- High Strength : Aluminum tank trucks have high strength and can withstand high pressure and heavy loads.

- Corrosion Resistance : The surface of the tank truck aluminum plate is treated to prevent oxidation and corrosion in harsh environments.

- Lightweight : Compared with traditional steel, the aluminum plate of the tank car is light in weight, which can reduce the weight of the vehicle itself and improve the load capacity and fuel economy.

- Beautiful : The surface of the tank truck aluminum plate is smooth and smooth, with high surface quality, easy to clean and maintain.

- Good Machinability : the tanker aluminum plate can be processed in various ways, such as bending, welding, stamping and so on.

What are the Advantages of using Aluminum Plates Over Steel in Tank Trucks?

- Aluminum is lighter than steel, making the tank truck more fuel-efficient and allowing for larger payloads.

- Aluminum has excellent corrosion resistance, especially in contact with various chemicals and liquids.

- Aluminum is highly recyclable and environmentally friendly.

Tank Truck Aluminum Plate Specifications

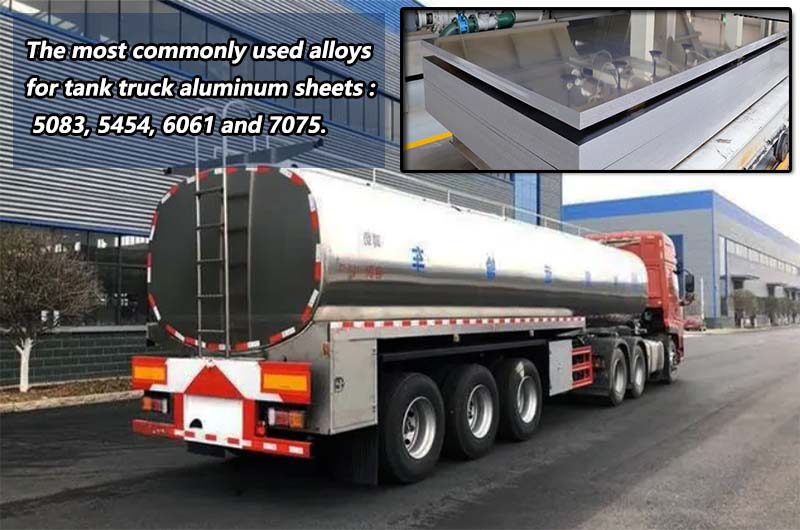

- Alloys : The most commonly used alloys for tank truck aluminum sheets are 5083, 5454, 6061 and 7075.

- Thickness : The thickness of the tank truck aluminum plate is usually between 5mm and 12mm, depending on the size and capacity of the tank.

- Width and Length : The width and length of the tank car aluminum plate can be changed according to the specific requirements of the tank body.

- Surface Treatment : The surface treatment of tank truck aluminum sheet can include polishing, brushing, anodizing and other types of surface treatments.

- Tensile Strength : The tensile strength of aluminum tank trucks is usually between 170-305 MPa, depending on the alloy and thickness.

- Yield Strength : The yield strength of tank truck aluminum plate is usually between 65-275 MPa, depending on the alloy and thickness.

- Elongation : The elongation of tank truck aluminum sheet is usually between 10-25%, depending on the alloy and thickness.

| Alloy | thickness(mm) | width(mm) | length(mm) |

|---|---|---|---|

| 5083 | 2.0-8.0 | 1000-2000 | 2000-12600 |

| 5052 | 2.0-8.0 | 1000-2000 | 2000-12000 |

| 5754 | 2.0-8.0 | 1000-2000 | 2000-12000 |

| 5454 | 2.0-8.0 | 1000-2000 | 2000-12000 |

| 5182 | 4.0-7.0 | 980-2200 | 800-9000 |

| Tank Truck Type | Typical Aluminum Sheet Thickness | Typical Aluminum Alloy |

|---|---|---|

| Oil Tank Truck | 5mm-12mm | 5083 aluminum alloy |

| Food Tank Truck | 2mm-4mm | 3003 aluminum alloy |

| Pharmaceutical Tank Truck | 1mm-4mm | 5052 aluminum alloy |

| Oxygen Tank Truck | 5mm-15mm | 5083 or 6061 aluminum alloy |

| Ammonia Tank Truck | 6mm-20mm | 5083 aluminum alloy |

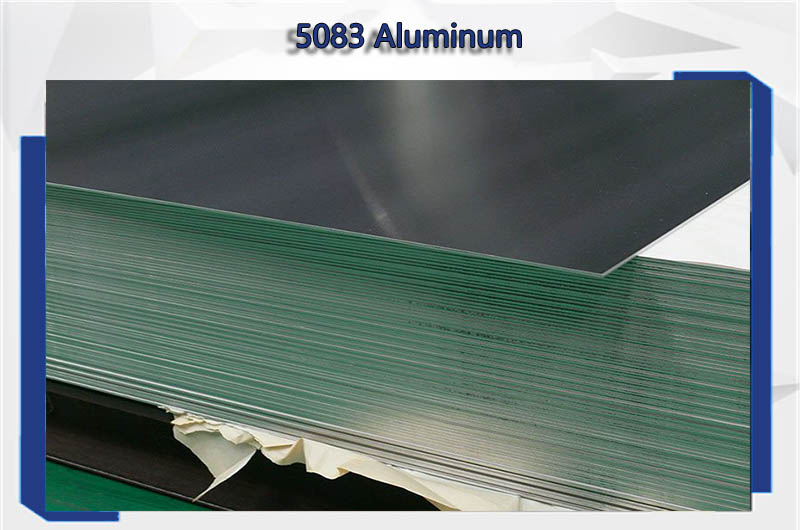

Typical Tank Car Aluminum Plate Introduction

The aluminum plate of the tank car can be made of different aluminum alloy materials, common ones include : 5 series aluminum alloy, 6 series aluminum alloy, 7 series aluminum alloy, etc.

5083 aluminum plate is a material widely used in the manufacture of fuel trucks. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance, and medium strength.

- 5182 Aluminum Plate Sheet for Tank Truck

- 5083 Aluminum Plate Sheet for Tank Truck

- 5754 Aluminum Plate Sheet for Tank Truck

- 5454 Aluminum Plate Sheet for Tank Truck

- 5059 Aluminum Plate Sheet for Tank Truck

- 3003 Checkered Aluminum Plate for Tank Truck

- 6082 Aluminum Plate Sheet for Tank Truck

- 5154 Aluminum Plate Sheet for Tank Truck

- 6061 Aluminum profiles for Tank Truck

- 6063 Aluminum profiles for Tank Truck

The 5182 aluminum plate is used in the latest high-magnesium alloy tank car that was born in recent years for the European Road Transport of Dangerous Goods Agreement. Its tensile strength and elongation are relatively high. The excellent quality of the 5182 alloy plate improves the safety of the aluminum alloy tanker.

5454 aluminum plate is suitable for aluminum-magnesium alloy tank cars used under high temperature conditions, and has strong corrosion resistance.

The length of aluminum plates commonly used in tank trucks on the market is generally within 12.5 meters, the width is less than 2.2 meters, and the common thicknesses are generally 5, 6, 7, and 8 mm. A complete tank truck body generally requires 4-6 aluminum plates to be welded.

-

5182 Aluminum Plate Sheet for Tank Truck

5182 is lighter than 5083 alloy and is the raw material for new dangerous goods transport tankers. It can be used in tanker cylinders, heads, bulkheads and other parts.

-

5083 Aluminum Plate Sheet for Tank Truck

5083 aluminum alloy plate for tank trucks is widely used to manufacture the tank bodies of oil tank trucks, Moss LNG tanks, semi-trailer tank trucks, and heavy truck gas storage tanks.

-

5754 Aluminum Plate Sheet for Tank Truck

5457 aluminum plates can be used to make tanks and bulkheads, which can reduce the weight of tank trucks, increase load capacity, reduce fuel consumption, and reduce exhaust emissions.

-

5454 Aluminum Plate Sheet for Tank Truck

5454 aluminum plate has high strength and good corrosion resistance. It can resist the corrosion of ordinary fuel and oil products and extend the service life of the tank truck.

-

5059 Aluminum Plate Sheet for Tank Truck

5059 aluminum plate has corrosion resistance, good weldability and low crack tendency. It is widely used in special tank trucks for dangerous goods such as petrochemical industry.

-

3003 Checkered Aluminum Plate for Tank Truck

The main advantages of 3003 Checkered Aluminum Plate for Tank Truck: good anti-skid performance, decorative effect, and low weight.

-

6082 Aluminum Plate Sheet for Tank Truck

6082 alloy aluminum plate is an alloy that can be strengthened by heat treatment and has good formability and weldability. It is often used to make protective floors for tank trucks.

-

6061 Aluminum profiles for Tank Truck

6061 aluminum alloy has good machinability, strength and toughness and is often used for the fence of tank trucks.

Which structures of tank trucks use aluminum plates?

The tank body is made of 5083H111 aluminum plate, The tank cover needs to be bent on both sides. Using 5083-O aluminum plate, O tempering is softer, The clapboard (anti-wave plate) is tempered with 5083-O.

- Aluminum Plate for Tanker Body

- Aluminum Plate for Tankers Cylinder

- Aluminum Plate for Tanker Head

- Aluminum Plate for Tanker Bulkhead

- Aluminum Plate for Tanker Wave Baffle

- Aluminum Plate for Gas Storage Tanks

- Aluminum Plate for Fuel Tank

- Aluminum Plate for Tank truck protective floor

- Aluminum for Tank truck Skin

- Aluminum for Tank truck fence

Aluminum is widely used in tank cars, mainly for parts such as tank body, tank cover, tank bottom and tank frame. Different parts need to use different types of aluminum alloys, the details are as follows :

- Tank body and tank cover : Generally, 5 series aluminum alloys are used, such as 5052, 5083, etc. These alloys have good corrosion resistance, weldability and machinability, and can effectively protect the safety and quality of stored substances during tanker transportation.

- Tank bottom : generally use 6 series aluminum alloy, such as 6061, 6063 and so on. These alloys have good mechanical properties, corrosion resistance and machinability, can withstand the weight and pressure of the tank car storage materials, and can also effectively prevent corrosion and damage of the tank bottom.

- Tank frame : generally use 6 series aluminum alloy or 7 series aluminum alloy, such as 6061, 7075, etc. These alloys have good mechanical properties, strength and toughness, can withstand the vibration and shock of tank trucks during transportation, and can also effectively prevent corrosion and damage to tank frames.

Aluminum Plate for Tanker Head

5083/5454/5182-O/H111 products have good plate shape and surface quality, and are used in tank truck heads and anti-wave boards

| Alloy | 5083 | 5454 | 5182 |

|---|---|---|---|

| Temper | O/H111 | O/H111 | O/H111 |

| thickness/mm | 4~8 | 4~8 | 4~8 |

| Rm/MPa | 300~320 | 240~270 | 285~295 |

| Rp0.2/MPa | 150~180 | 95~125 | 145~175 |

| A50mm/% | 20~23 | 20~23 | 27~30 |

| Bending performance(180º) | 1.5t(t≤6.3) 2.5t(t>6.3) | 1t(t≤6) 2t(t>6) | 1 t(t≤6) 2t(t>6) |

Aluminum Plate for Tanker Wave Baffle

5083/5454/5182-O/H111 products have good plate shape and surface quality, and are used in tank truck heads and anti-wave boards.

| Alloy | 5083 | 5454 | 5182 |

|---|---|---|---|

| Temper | O/H111 | O/H111 | O/H111 |

| thickness/mm | 4~8 | 4~8 | 4~8 |

| Rm/MPa | 300~320 | 240~270 | 285~295 |

| Rp0.2/MPa | 150~180 | 95~125 | 145~175 |

| A50mm/% | 20~23 | 20~23 | 27~30 |

| Bending performance(180º) | 1.5t(t≤6.3) 2.5t(t>6.3) | 1t(t≤6) 2t(t>6) | 1 t(t≤6) 2t(t>6) |

Aluminum Plate for Tanker Body

5083-H32/5454-H32/5182-O/H111 products meet both strength requirements and bending requirements, and have good plate shape and surface quality, and are used in tank truck cylinders.

| Alloy | 5083 | 5454 | 5182 |

|---|---|---|---|

| Temper | H32 | H32 | O/H111 |

| thickness/mm | 4~8 | 4~8 | 4~8 |

| Rm/MPa | 320~350 | 280~295 | 285~295 |

| Rp0.2/MPa | 215~240 | 190~220 | 145~175 |

| A50mm/% | 13~15 | 13~15 | 27~30 |

| Bending performance(180º) | 3t(t≤6.3) 6t(t>6.3) | - | 1t(t≤6) 2t(t>6) |

Aluminum for Tank truck fence

6061-T6 extruded product with medium strength for insulation tank fencing.

| Alloy | 6061-T6 |

|---|---|

| Rp0.2(MPa) | 260 |

| Rm(MPa) | 320 |

| A50mm(%) | 17 |

Aluminum for Tank truck fence

5083-O product has good plate shape and surface quality, and is used for skinning of thermal insulation tanks.

| Alloy | 5083 |

|---|---|

| Temper | O |

| thickness/mm | 2~3 |

| Rm/MPa | 300~320 |

| Rp0.2/MPa | 150~180 |

| A50mm/% | 20~23 |

| Bending performance(180º) | 1.5t |

-

-

5454 Aluminum Plate Sheet

5454 Aluminum Plate SheetStable Performance, Precise Dimensional Tolerance

Smooth Surface, Uniform Thickness

-

-

Chemical composition of tank truck aluminum plate alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other(%) | |

| Single | Total | |||||||||

| 5083 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.05 | 0.15 | |

| 5754 | 0.40 | 0.40 | 0.10 | 0.05 | 2.6-3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 |

| 5454 | 0.25 | 0.40 | 0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.20 | 0.05 | 0.15 |

| 5182 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 |

Mechanical properties of tank truck aluminum plates

| Alloy | Temper | Tensile Strength Rm(MPa) | Yield Strength Rp. 02(MPa) | Elongation |

| 5083 | O/H111 | ≥275 | ≥125 | ≥15 |

| H112 | ≥275 | ≥125 | ≥12 | |

| 5052 | O/H111 | 170-215 | ≥65 | ≥16 |

| H112 | ≥190 | ≥80 | ≥7 | |

| 5754 | O/H111 | 190-240 | ≥80 | ≥16 |

| H112 | ≥190 | ≥80 | ≥7 | |

| 5454 | H32 | ≥250 | ≥180 | ≥8 |

| 5182 | O/H111 | ≥280 | ≥125 | ≥26 |

Which tank trucks use aluminum plates?

Tank trucks are transport vehicles with a tank-shaped body, used to transport various liquids, liquefied gases, and powdered goods.

- Aluminum Plate for Semi Tanker

- Aluminum Plate for Fuel Tanker

- Aluminum Plate for Oil Tanker

- Aluminum Plate for LNG Tanker

- Aluminum Plate for Load Tanker

- Aluminium Plate for Road Tank Trailers

- Aluminum Plate for Trailer Tank

- Aluminum Sheet for Heavy Truck Air Reservoir

- Aluminum Sheet for Truck

- Aluminum Plate for Cement tanker

- Aluminum Plate for Powder tank truck

Aluminum Plate for Semi Tanker

Semi Tankers are mainly used for the transportation of different substances which may be liquids, powders or gases, depending on the design purpose.

Aluminum Plate for Fuel Tanker

Fuel Tanker transport materials are generally liquid fuels, such as gasoline, diesel, etc. Choose aluminum plates with strong corrosion resistance and lightweight.

Aluminum Plate for Oil Tanker

Oil Tanker mainly transports liquid oil products, and generally uses aluminum plates with good corrosion resistance and lightweight properties.

Aluminum Plate for LNG Tanker

Liquefied natural gas tankers (LNG Tankers) generally use 5083 aluminum plates. 5083 aluminum alloy has the advantages of high strength, good plasticity, corrosion resistance and good processing performance. It has become a widely used material for manufacturing low-temperature storage tanks such as LNG storage tanks and LNG ships.

Aluminum Plate for Trailer Tank

5083 aluminum plate is the main aluminum alloy plate of Trailer Tank. It has high strength, corrosion resistance, good processability, and excellent arc weldability. It is very suitable for tank materials after welding aluminum plates.

Aluminum Sheet for Truck

Truck's frame, gearbox, fuel tank, gas storage bottle and many other parts are made of aluminum alloy materials, often with the grade 5083 aluminum plate.

Aluminum Plate for Cement Tanker

Tanker type: Cement Tanker uses aluminum plates to ensure the tank’s light weight and corrosion resistance.

Aluminum Plate for Powder Tank Truck

Transported materials: Powdered materials, such as powdered fertilizers, flour, etc. Choose aluminum plate: Aluminum plate with sufficient strength and lightness is required.

Aluminum Sheet for Heavy Truck Air Reservoir

Heavy Truck Air Reservoir compressed air for use in trucks’ braking systems.

Aluminum Plate for Road Tank Trailers

Transport substances: liquid or gas, etc., depending on needs. Choose aluminum panels: Aluminum panels are corrosion-resistant and lightweight.

Aluminum Plate for Load Tanker

The transported substances may be a variety of different goods, depending on the intended use. Due to the low density of aluminum alloy, it is more than 4 tons lighter than similar carbon steel tank trucks, and its load capacity is 20% greater than that of carbon steel tank trucks.

| Surface Treatment Method | Tanker Type | Common Aluminum Alloy |

|---|---|---|

| Sandblasting | Food tankers, Water tankers | 5083 Aluminum Alloy |

| Galvanizing | Oil tankers | 5052 Aluminum Alloy |

| Oxidation | Medical tankers, Oxygen tankers | 6061 Aluminum Alloy |

| Original color | Medical tankers | 5083 Aluminum Alloy |

| Production Process | Tanker Type | Common Aluminum Alloy |

|---|---|---|

| Welding | Chemical tankers, Food tankers | 5083 Aluminum Plate |

| Thin-walled stretching | Oil tankers, Powder material tankers | 5454 Aluminum Plate |

| Stamping | Coke tankers, Compactor garbage trucks | 6061 Aluminum Plate |

| Forging | Hydraulic tankers, Aviation fuel tankers | 7075 Aluminum Plate |

What Thickness Aluminum for Fuel Tank

The thickness of aluminum for fuel tanks depends on several factors, including the size and shape of the tank, the type of fuel it is carrying, and the intended use and application of the tank. Typically, fuel tanks for commercial trucks and other heavy vehicles are made from sheet aluminum ranging in thickness from 1/8 inch (3.175 mm) to 3/16 inch (4.763 mm).

It should be noted that the thickness of the aluminum plate itself does not determine the strength and safety of the fuel tank. A fuel tank must also be designed, constructed and welded to meet strict safety standards and regulations to ensure it can withstand the stress and pressure of use and prevent fuel from leaking or exploding.

Frequently Asked Questions (FAQs) about Aluminum Plates for Tank Trucks

NO1. Are Aluminum Tank Trucks Suitable for Transporting Hazardous Materials?

Yes, aluminum tank trucks can be used to transport hazardous materials. The choice of alloy and tank design must meet regulatory requirements and safety standards for the specific cargo.

NO2. How is the Integrity of Aluminum Tank Truck Plates Maintained Over Time?

Regular inspection and maintenance are essential to ensure the integrity of aluminum tank truck plates. This includes checking for corrosion, cracks, and other signs of wear, and promptly addressing any issues.

NO3. Can Aluminum Tank Truck Plates be Repaired if Damaged?

Yes, damaged aluminum tank truck plates can often be repaired, depending on the extent of the damage. Repairs typically involve welding or patching using compatible aluminum materials and techniques.

NO4. Do Aluminum Tank Truck Plates Require Special Cleaning or Maintenance for Specific Cargo Types?

Yes, different cargoes may require specific cleaning and maintenance procedures to prevent contamination and ensure safety. Proper cleaning and maintenance protocols should be followed as per industry regulations.

NO5. Can Aluminum Tank Truck Plates be Recycled at the end of Their Service Life?

Yes, aluminum is highly recyclable. At the end of a tank truck's service life, the aluminum plates can be recycled, contributing to sustainability and reducing the environmental impact.

Haomei Aluminum Tank Car Aluminum Plate Quality

- Reasonable selection of alloys : Tanker aluminum plates of different alloys have different characteristics and scope of application. In order to ensure the quality of the tank car aluminum plate, it is necessary to make a reasonable choice when selecting the alloy to ensure that the selected alloy can meet the use requirements of the tank car.

- Strictly control the production process : the tank car aluminum plate strictly controls the production process to ensure that every link can be effectively controlled and supervised to avoid unstable quality of the tank car aluminum plate due to production process problems.

- Strict inspection standards : After the aluminum plates for tank cars are produced, they are strictly inspected and tested. Refer to relevant standards and specifications when conducting inspections to ensure that the inspection results can reflect the actual situation of the aluminum plate of the tank car.

Note : The tanker aluminum plate needs regular maintenance and maintenance during use to ensure its long-term stable operation. Periodic inspection and maintenance, as well as necessary repairs and replacements, are required.

Other aluminum material information for tank trucks

- 5083 Aluminum Plate For Oil Tanker Body

- Oil Tanker Aluminum Plate 5754

- Aluminum Alloy For Tanker Making

- 5083 O H321 Oil Tanker Aluminum Plate

- 5182 Aluminum Sheet For Petroleum Tanker

- 6061 Oil Tanker Aluminum Tube

- Aluminum Alloy 5083-H111 For Tanker Body

- Aluminium Wide Plate For Tankers

- 6063 T4 T6 Oil Tanker Aluminum Tube

- Aluminum 5059 for Fuel Tank

- 5083 Aluminum Plate For Tank Truck Body

- 5083 Cast Aluminum Plate for LNG Tank

- Aluminium Alloy 5182-H111 For Tanker Body

- 5182 Aluminum Sheet for Truck

- 5754 O H111 Oil Tanker Aluminum Sheet

- Aluminium Alloy 5083 O For Tanker Body

- 5182 O H111 Oil Tanker Aluminum Plate