- Marine Grade Aluminum Plate Market Demand

- Marine Grade Aluminum Plate Key Drivers of Demand

- Marine Grade Aluminum Plate Parameter

- Typical Marine aluminum plate

- Aluminum alloy for hull structure

- Marine Aluminum Plate Applications

- How to Choose Marine Grade Aluminum Plate

- Marine Aluminum Plate Quality Assurance

- Marine Grade Aluminum Plate for Sale

- What Aluminum is Best for Marine Use?

- Notices for using Marine Grade Aluminum

- Other marine aluminum materials

Marine Grade Aluminum Plate Market Demand

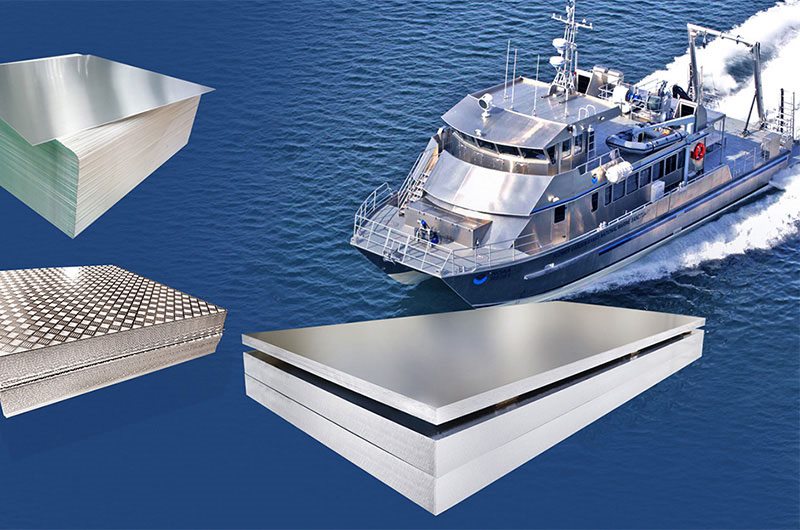

Demand for marine grade aluminum plates is primarily driven by the shipbuilding and marine industries. These plates are used in the construction of various marine vessels, offshore structures, and components due to their excellent corrosion resistance, lightweight properties, and durability.

Haomei Aluminum provides marine aluminum panels, patterned aluminum panels, foam aluminum panels, honeycomb aluminum panels and anodized anti-corrosion aluminum panels. The products have ABS, BV, CCS, DNV, KR, LR, NK, RINA and other certifications, and meet the requirements of light weight, high strength, corrosion resistance, weather resistance, rust prevention and welding in the shipbuilding field.

Marine Grade Aluminum Plate Certifications:

- DNV

- BV

- CSS

- LR

Marine Grade Aluminum Plate Key Drivers of Demand

- Environmental Regulations: Stringent environmental regulations and the need for eco-friendly and fuel-efficient vessels have increased the demand for lightweight materials like marine grade aluminum.

- Growing Maritime Trade: The global increase in maritime trade has led to the construction of larger and more efficient vessels, creating a demand for advanced materials like marine grade aluminum.

- Offshore Energy Industry: The offshore oil and gas sector continues to require specialized vessels and structures, driving demand for marine grade aluminum plates.

- Recreational Boating: The recreational boating industry also contributes to the demand for marine grade aluminum, as boat manufacturers seek materials that offer a balance between strength and weight.

The most commonly used alloys for marine aluminum plates are the 5000 and 6000 series, which are mainly used in shipbuilding, offshore platforms and other marine structures.

Not all aluminum panels are suitable for use in marine environments and using the wrong type of aluminum can lead to corrosion and structural failure. If you are working on a marine project and need to use aluminum, it is very important to choose marine grade aluminum plate.

Marine Grade Aluminum Plate Parameter

Marine aluminum alloy

- 3000 series: 3003, 3004 level, etc.

- 5000 series: 5052, 5083, 5086, 5252, 5383, 5454, 5456, 5754, etc.

- 6000 series: 6061, 6063, etc.

Temper

O, H16, H32, H111, H116, H321, T6, T 321 etc.

Thickness

.125 inch, 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 5mm, 6mm, 10mm (thick) etc

Size

4×8 ft, 12000mm x 2000mm, 1500 mm x 6000 mm etc.

-

-

-

-

5454 Aluminum Plate Sheet

5454 Aluminum Plate SheetStable Performance, Precise Dimensional Tolerance

Smooth Surface, Uniform Thickness

These specifications may vary depending on the specific application and requirements of the marine grade aluminum sheet. It is important to consult the boat plate supplier or manufacturer to determine the proper specifications for your application.

After special treatment, the ship's aluminum plate can be used in water or humid environments. Generally, this is achieved by adding special alloys to the metal to make it corrosion.

Structural steel has excellent mechanical properties and low manufacturing costs, and is a traditional material for the shipbuilding industry. However, more and more demand is getting bigger and bigger, but the light boats make designers find alternative materials. Aluminum alloy is a good choice because they are highly corrosive and light weight, and are considered to be conducive to long -term economic development.

Typical Marine aluminum plate

- 5083 Marine Aluminum Plate

- 5086 Marine Aluminum Plate

- 5754 Marine Aluminum Plate

- 5454 Marine Aluminum Plate

- 5059 Marine Aluminum Plate

- 5052 Marine Aluminum Plate

- 6082 Marine Aluminum Plate

- 5456 Marine Aluminum Plate

- 5383 Marine Aluminum Plate

- 6063 Marine Aluminum Plate

- 6061 Marine Aluminum Plate

- Marine Grade Aluminum Wire

- Marine Aluminum checkered plate

-

5083 Marine Aluminum Plate

5083 ship aluminum plate is a typical Al-Mg-SI alloy, which has high corrosion resistance and rust resistance, especially in seawater. 5083 aluminum plates are used for ships, outer boards, and side bottom plates.

-

5086 Marine Aluminum Plate

The 5086 aluminum plate is also a ship -made aluminum alloy plate with a high degree of application in ship manufacturing. Due to its excellent corrosion resistance and rust resistance, it is often used as the underwater part of the hull due to its excellent corrosion resistance and rust resistance.

-

5754 Marine Aluminum Plate

The 5754 shipping aluminum plate has excellent corrosion resistance, especially the pollution of seawater and industrial pollution. 5754 ship aluminum plates are widely used in welding structures, tanks, pressure vessels and other ship structures.

-

5454 Marine Aluminum Plate

5454 ship aluminum plate 5454 aluminum plate has a higher strength than the 5052 of the ship 5052. 5454 aluminum plates for alloy ships are suitable for the ship structure. Compared with the 5086 ship's aluminum plate and 5083, 5454 has medium formability.

-

5059 Marine Aluminum Plate

5059 aluminum has excellent comprehensive performance and is often used in marine engineering such as large cruise ships. Large production capacity, 5059 aluminum plate prices are competitive.

-

5052 Marine Aluminum Plate

Compared with 5083 aluminum plates, 5052 aluminum plates are lower. In ship manufacturing, it is mostly used on small ships and ship components, such as: cable bridge on board.

-

6082 Marine Aluminum Plate

Ship -grade aluminum 6082 has medium -strength and good welding, corrosion resistance, and light weight, making it an ideal material for high -speed ship components. Its T6 state has higher mechanical performance.

-

5456 Marine Aluminum Plate

5456 shipping aluminum plate is an economic choice for ships. Can be used for the bottom plate, deck and other upper accessories.

-

5383 Marine Aluminum Plate

Due to its higher intensity and better welding performance, 5383 shipping aluminum plates are widely used in high -speed ships, such as ship deck and hull components.

-

6063 Marine Aluminum Plate

The anode oxidation 6063 ship aluminum extrusion factories are mainly used for frame structures such as portholes or ship containers. AL 6063 is high in hardness and is not easy to break, which can ensure the safety of liquid in the container.

-

6061 Marine Aluminum Plate

6061 ship grade aluminum 6061 has good processing and strength, which is very suitable for making parts such as ship structure and reinforcement of hull. But it is not as durable as 5052 aluminum alloy. The common 6061 aluminum alloy status includes T6, T651, and T6511.

-

Marine Grade Aluminum Wire

The welding of aluminum plates for ships often uses 5183 and 5356 aluminum wires with higher magnesium content. They have excellent corrosion resistance and heat resistance.

-

Marine Aluminum Checkert Plate

3003 aluminum plate is an aluminum plate with better rust -proof effects. It is commonly used in the fields of ship components and anti -slide plates, such as: ship sinks, cabin anti -skateboards, etc.

Aluminum alloy for hull structure

According to the use site, it is divided into aluminum alloys and hull structures. The on -board installation includes masts, portholes, chimneys, cabs, engine tables, etc. The hull structure includes the turban, decks, panels, keels, vessel sides, outer boards of the bottom of the ship.

- Aluminum plate for ship deck

- Aluminum profile for keel

- Aluminum plate for ship chimney

- Aluminum plate for ship side and ship bottom

- 1. 6063 and 6061 aluminum alloys are usually used in masts and rangers.

- 2. The amount of shipping aluminum plates commonly used in hull structures is high, of which 5454 and 5052 aluminum alloy are the main materials for making deck.

- 3. 5083, 5052, and 5086 alloys can be used to better resist the erosion of the seawater and extend the service life of the ship.

- 4. The top plates and side boards of sea ships can be used 3003, 3004 and 5052, which can effectively reduce the rust of the top board to a certain extent.

- 5. The cab is 5083 and 5052 aluminum plates. Because the aluminum plate is not magnetic, the compass will not be affected, and it can ensure the correct direction of the ship's sailing.

- 6. The top plate and side plate of the ship container can be selected from 3003 aluminum plates, 3004 aluminum plates, and 5052 aluminum plates. 3003 aluminum plate has a good rust -proof effect. Under the influence of long -term sea and rain, the corrosion of the roof has been reduced.

| Use | Alloy | Product Type |

|---|---|---|

| On the side of the ship, the outside of the ship | 5083, 5086, 5456, 5050 | Plate, profile |

| keel | 5083 | Plate |

| rib cage | 5083 | Profile, board |

| Ribs, next door | 5083, 6061 | Plate |

| Engine table | 5083 | Plate |

| deck | 5052, 5083, 5086, 5454 | Plate, profile |

| Rudder | 5083, 6N01, 5052 | Plate, profile |

| Wall | 5083 | Plate, profile |

| Cigarette tube | 5083, 5052 | Plate |

| The top board and side board of the sea boat container | 3003, 3004, 5052 | Plate |

| Porthole | 5052, 5083, 6063, AC7A | Profile, casting |

| gangway | 5052, 5083, 6063, 6060 | Profile |

| Mast | 5052, 5083, 6063, 6060 | Tube, stick, profile |

| Structural material of maritime ship container | 6063, 6061, 7003 | Profile |

Marine Aluminum Plate Applications

Boat aluminum plates are mainly used in yachts, grain ships, fishing boats, workboats, sand shipping, LNG cargo ships, and so on.

- Aluminum plate for yachts building

- Aluminum plate for fishing boat

- Aluminum plate for LNG cargo ship

- Al Alloy 5083 for Small Boat Building

-

DNV shipping level 5083 aluminum plate for yacht

The main two alloys of manufacturing yachts are 5052 and 5083 aluminum plates. The 5083 magnesium content of ship -grade aluminum is high, greater, and harder, but it has better corrosion resistance and higher strength than 5052 aluminum plates.

-

Aluminum Plate for Fishing Boat

There are many types of aluminum alloy fishing vessels, suitable for different waters. It has a thick shell, with super high strength and security. The weight of aluminum alloy ship is light, and the fuel -saving effect is obvious.

-

Aluminum Plate for LNG Cargo Ship

LNG is the main way to transport natural gas long -distance transportation. When designing the LNG ship storage tank, it is necessary to ensure that the liquefied natural gas does not leak, fire, or corroded storage tanks. Aluminum alloys are not only a low -temperature metal, but also have good strength and toughness, light weight and excellent corrosion resistance. 5083 aluminum plates are often used to make LNG storage tanks.

-

Al Alloy 5083 for Small Boat Building

5052-H32, 5052-H34, or 6061-T6 ship aluminum plates are used to use small hulls without stretching. In the case of stretching, the 6061-T4 board can be used, and then it can be effective to the T6 state.

How to Choose Marine Grade Aluminum Plate

- Corrosion resistance : Ships are often exposed to the marine environment, and aluminum plates with good corrosion resistance need to be selected to avoid corrosion damage to the aluminum plates during long-term use. Alloys 5083 and 5086 generally have excellent corrosion resistance and are among the most common alloys used in marine construction.

- Strength : Ships need to have sufficient strength to cope with complex ocean environments such as waves and wind waves, so high-strength aluminum plates need to be selected to ensure the stability and durability of the hull. Alloys 5083 and 5454 generally have higher strength and are suitable for hull plating, frames and supporting structures.

- Processability : In shipbuilding, aluminum plates need to be cut, bent, welded, etc., so aluminum plates with good processability need to be selected. 5052 and 6061 alloys generally have good machinability.

- Cost : The cost factor also needs to be considered when choosing a marine grade aluminum plate to ensure that the selected material can meet the requirements within the budget. Generally speaking, higher-grade aluminum panels cost more, and you need to choose the right material according to your actual needs and budget.

Marine Aluminum Plate Quality Assurance

- Chemical composition : The chemical composition in the marine grade aluminum sheet complies with relevant international or industry standards.

- Physical properties : Marine-grade aluminum plates have sufficient strength, hardness, plasticity and corrosion resistance to ensure their safety and reliability during ship construction and use.

- Appearance quality : There are no cracks, bubbles, inclusions and other defects in the appearance of the marine-grade aluminum plate, and the surface finish and flatness meet the relevant standards.

- Production technology : Marine grade aluminum plate adopts advanced production technology and production equipment, and perfect quality control system.

Marine Grade Aluminum Plate for Sale

Thanks to customers who trust us and give us a chance, each "Alu Plate Marine" has been strictly tested to ensure stable performance and customer satisfaction.

What Aluminum is Best for Marine Use?

When it comes to marine aluminum, the most commonly used alloy is 5083. This alloy has excellent corrosion resistance and high strength, making it suitable for use in marine environments. Additionally, 5083 aluminum alloy is known for its excellent weldability, which is important for building ships and other marine structures.

Another alloy that is often used in marine applications is 5052. The alloy has good corrosion resistance and high formability, which makes it useful for making complex shapes for boat hulls and other marine components.

It is important to note that while aluminum is a popular marine material, it is not immune to corrosion. Proper maintenance and regular inspections are essential to ensure the longevity and safety of any aluminum marine structure.

Notices for using Marine Grade Aluminum

When using marine grade aluminum in various applications, especially in marine and maritime environments, it's essential to follow specific notices and best practices to ensure the material's longevity, performance, and safety. Here are some important notices for using marine grade aluminum:

1. Material Selection

Choose the appropriate alloy and temper of marine grade aluminum based on the specific application and environmental conditions. Common marine alloys include 5083, 5086, and 6061.

2. Corrosion Protection

Marine environments are highly corrosive due to exposure to saltwater. Ensure that the aluminum is adequately protected against corrosion through methods such as anodizing, painting, or applying protective coatings.

3. Regular Inspection

Implement a routine inspection schedule to check for signs of corrosion, damage, or wear. Pay particular attention to areas where aluminum is in contact with other materials or exposed to saltwater.

4. Maintenance

Regularly clean and maintain marine grade aluminum components or structures. Remove salt deposits and other contaminants to prevent corrosion.

5. Galvanic Corrosion

Be cautious of galvanic corrosion when using aluminum in proximity to other metals, such as steel or bronze. Use appropriate isolators or sacrificial anodes to mitigate this type of corrosion.

6. Welding Practices

If welding marine grade aluminum, ensure that welds are of high quality and that proper welding techniques are followed. Consult with a skilled aluminum welder or engineer for best practices.

7. Fasteners and Hardware

Use compatible fasteners and hardware made of materials that are compatible with marine grade aluminum. Avoid using materials that can promote galvanic corrosion.

8. Avoid Impact and Abrasion

Protect aluminum components from impact, abrasion, and physical damage, as this can compromise the material's integrity and corrosion resistance.

9. Load Limits

Adhere to specified load limits and structural design guidelines when using marine grade aluminum in structural applications, such as boat hulls or offshore platforms.

10. Electrical Isolation

Ensure proper electrical isolation when installing electrical equipment or components on aluminum structures to prevent electrical corrosion

Other marine aluminum materials

- 6061 6082 Marine Aluminum Round Bars

- 5083 h116 aluminum sheet for boat

- Marine Grade 5A02 Aluminum Hexagonal Bar

- 5083 aluminum plate for boat

- 5083 boat aluminum sheet

- 5083 aluminium sheet for shipbuilding

- 10mm thickness aluminum plate for boat

- 5083 h32 marine aluminum plate

- 5083 aluminum sheet for boat

- 5A06 Marine Grade Aluminum Plate

- 3.5mm aluminum sheet marine

- 6082 O T6 Marine Aluminum Square Bar

- 5052 aluminum sheet for boat

- 4x8 marine grade 5083 aluminum sheet

- 5052 5083 marine grade aluminum sheet

- 5083 5383 Marine Grade Aluminum Hexagon Bar

- 5083 h321 aluminium alloy plate for marine

- 5052 O H112 Marine Grade Aluminum Round Bars

- 5059 5086 Marine Grade Aluminum Square Bars

- 10mm thickness marine aluminium plate 5083

- 3.5mm marine aluminum sheet price per tons

- 5052 O H112 Marine Grade Aluminum Square Bar

- 5083 5383 O H112 Marine Aluminum Square Bar

- 5083 h116 marine grade aluminium alloy sheet

- 5052 O H112 Marine Grade Aluminum Hexagon Bar

- 5754 H111 H112 Marine Grade Aluminum Plate

- 5052 marine grade aluminium alloy sheet

- 5052 5a02 5252 h32 aluminium sheet for marine

- 5456 5454 5754 Marine Grade Aluminum Round Bar

- 16ft welded yacht fishing boat aluminum sheets

- 5083 h116 marine grade aluminium sheet for boat

- 5083 5383 O H112 Marine Grade Aluminum Round Bars

- 5083 O H111 H116 H321 Marine Grade Aluminum Plate

- 5059 H112 5086 O/H112 Marine Grade Aluminum Bars

- 5456 5454 5754 Marine Grade Aluminum Square Bars

- Marine Grade 5454 5456 5754 Aluminum Hexagonal Bar

- 5059 H112 5086 O H112 Marine Grade Aluminum Hexagon Rod

- 5059 O H111 H116 H321 Marine Grade Aluminum Plate Sheet

- 6061 O/T6/T4/ T3511/T8511 Marine Aluminum Square Bar for Shipbuilding