- Corrugated Aluminum Sheet Plate Functions and Advantages

- Commonly Used Thickness for Corrugated Aluminum Sheet Plates

- Common Specifications of Corrugated Aluminum Sheet Plates

- Commonly Used Alloy for Corrugated Aluminum Sheet Plates

- List of Common Application Examples

- Common Problems with the use of Corrugated Aluminum Plates

- Concerns When Purchasing Corrugated Aluminum Sheet Plates

- How to Choose the Right Corrugated Aluminum Sheet Plates

- Related search about Corrugated Aluminum Sheet Plate

- People also Ask about Corrugated Aluminum Sheet Plate

- Conclusion

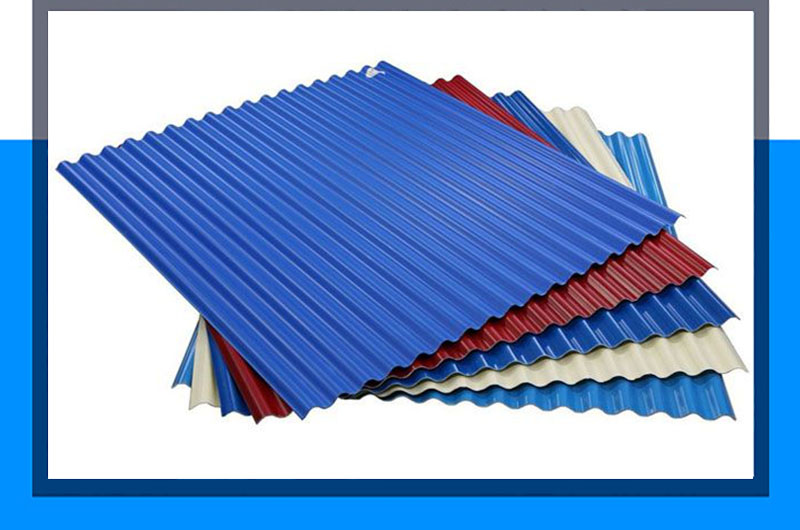

Corrugated aluminum sheet plates have gained widespread popularity in various industries due to their unique characteristics and versatility. These sheets, known for their strength, durability, and corrosion resistance, serve a multitude of purposes across construction, transportation, and manufacturing sectors.

In this comprehensive guide, we will delve into the functions, advantages, considerations for purchasing, common alloys, selection criteria, applications, specifications, and thickness options of corrugated aluminum sheet plates.

Corrugated Aluminum Sheet Plate Functions and Advantages

Structural Integrity and Durability

Corrugated aluminum sheet plates are celebrated for their exceptional strength, providing structural integrity in a variety of applications. The corrugated pattern enhances the overall durability of the sheets, making them ideal for use in environments with high stress and load-bearing requirements.

Corrosion Resistance

The natural oxide layer on aluminum lends excellent corrosion resistance to these sheets. This feature makes corrugated aluminum sheet plates suitable for outdoor applications where exposure to the elements is a concern.

Lightweight

Compared to other metals, aluminum is relatively lightweight, making corrugated sheets easy to handle during installation. This characteristic is particularly advantageous in construction and transportation industries where weight is a critical factor.

Aesthetic Appeal

Corrugated aluminum sheets offer a sleek and modern appearance, adding an aesthetic appeal to architectural designs. This makes them a popular choice for roofing, siding, and interior design applications.

Commonly Used Thickness for Corrugated Aluminum Sheet Plates

The choice of thickness for corrugated aluminum sheet plates depends on the specific requirements of the application. Common thickness options and their applications include:

0.016 inches (0.4 mm) to 0.032 inches (0.8 mm) Corrugated Aluminum Sheet Plate

Suitable for decorative applications, interior design, and projects where weight is a critical factor.

0.040 inches (1.0 mm) to 0.063 inches (1.6 mm) Corrugated Aluminum Sheet Plate

Ideal for roofing and siding applications where a balance of strength and weight is essential.

0.080 inches (2.0 mm) and above Corrugated Aluminum Sheet Plate

Used in heavy-duty applications, such as industrial flooring, where increased load-bearing capacity is required.

Common Specifications of Corrugated Aluminum Sheet Plates

Corrugated aluminum sheet plates are available in various specifications, catering to diverse applications. Common specifications include:

Sheet Width

Corrugated aluminum sheets come in various widths to accommodate different project requirements. Common widths range from 26 inches to 48 inches.

Sheet Length

The length of corrugated sheets can vary based on the manufacturer and customer specifications. Standard lengths typically range from 8 feet to 20 feet.

Thickness Options

Corrugated aluminum sheets are available in a range of thicknesses. Common thickness options include 0.016 inches (0.4 mm) to 0.080 inches (2.0 mm), with variations depending on the application.

Corrugation Profile

The profile of the corrugations can vary, influencing the aesthetic appearance and performance of the sheets. Common profiles include U-shaped, V-shaped, and trapezoidal corrugations.

Commonly Used Alloy for Corrugated Aluminum Sheet Plates

Aluminum alloys are carefully chosen to suit specific applications. Common alloys for corrugated aluminum sheet plates include:

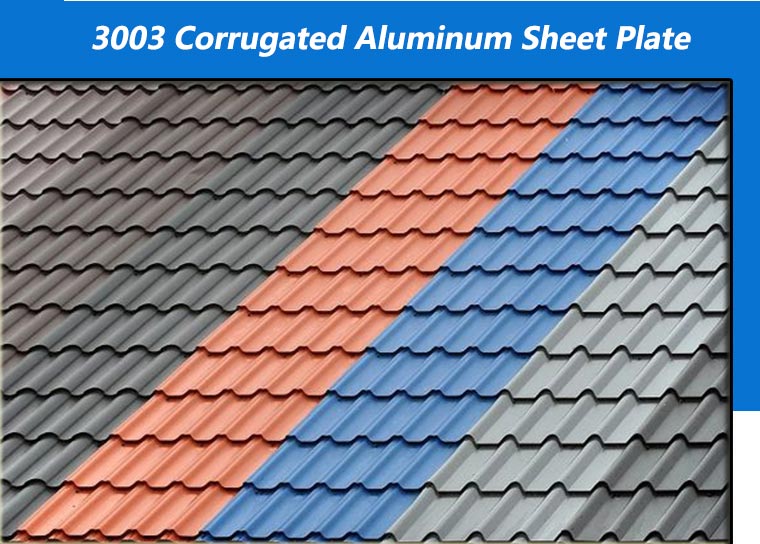

3003 Corrugated Aluminum Sheet Plates

This alloy is known for its excellent corrosion resistance and formability. It is often used in applications where moderate strength and high corrosion resistance are required.

5052 Corrugated Aluminum Sheet Plates

5052 aluminum alloy offers a good balance of strength and corrosion resistance. It is commonly used in marine applications due to its resistance to saltwater corrosion.

6061 Corrugated Aluminum Sheet Plates

Recognized for its high strength and heat-treatable properties, 6061 alloy is chosen for applications requiring enhanced structural integrity.

List of Common Application Examples

Corrugated aluminum sheet plates find applications in a wide range of industries. Some common examples include:

Corrugated Aluminum Sheet Plates for Roofing

Corrugated aluminum sheets are widely used for roofing applications due to their lightweight nature, durability, and resistance to corrosion.

Corrugated Aluminum Sheet Plates for Cladding and Siding

The aesthetic appeal of corrugated aluminum sheets makes them a popular choice for cladding and siding in architectural designs.

Corrugated Aluminum Sheet Plates for Transportation

The lightweight yet robust nature of corrugated aluminum makes it an ideal material for applications in the transportation industry, including trailers and truck bodies.

Corrugated Aluminum Sheet Plates for Flooring and Decking

Corrugated aluminum sheets can be employed as flooring and decking material in industrial settings where strength and corrosion resistance are crucial.

Corrugated Aluminum Sheet Plates for Decorative Applications

The modern and sleek appearance of corrugated aluminum sheets makes them suitable for decorative purposes in interior design and architectural projects.

Common Problems with the use of Corrugated Aluminum Plates

When considering the purchase of corrugated aluminum sheet plates, customers typically have specific needs and requirements in mind. Here are some factors to consider:

Application Requirements

Understand the intended application of the corrugated sheets. Whether it's for roofing, cladding, flooring, or another purpose, the specific application will dictate the required characteristics such as thickness, alloy, and finish.

Environmental Conditions

Consider the environmental conditions the sheets will be exposed to. If the application involves exposure to harsh weather conditions or corrosive environments, selecting a corrosion-resistant alloy is crucial.

Load-Bearing Capacity

Evaluate the load-bearing requirements of the project. Corrugated aluminum sheet plates are known for their strength, but choosing the right thickness and alloy is essential to ensure they can withstand the intended loads.

Aesthetic Preferences

If appearance is a significant consideration, customers may want to explore different finishes and colors available for corrugated aluminum sheets. Some applications may require specific coatings for enhanced durability or UV resistance.

Concerns When Purchasing Corrugated Aluminum Sheet Plates

Cost Considerations

The cost of corrugated aluminum sheet plates can vary based on factors such as alloy type, thickness, and finish.

Installation Challenges

Depending on the application, installing corrugated aluminum sheets may pose specific challenges.

Compatibility with Other Materials

In some cases, corrugated aluminum sheets may be used in conjunction with other materials. Ensuring compatibility with these materials and assessing potential galvanic corrosion issues is essential for the long-term performance of the installation.

How to Choose the Right Corrugated Aluminum Sheet Plates

Choosing the right corrugated aluminum sheet plates involves considering several key factors:

Application-Specific Requirements

Identify the specific requirements of the intended application, such as load-bearing capacity, corrosion resistance, and thermal properties.

Alloy Selection

Choose an alloy that aligns with the environmental conditions and performance expectations of the project. Consultation with material experts or suppliers can help in selecting the appropriate alloy.

Thickness Considerations

The thickness of corrugated aluminum sheets is a critical factor in determining their strength and load-bearing capacity. Thicker sheets are generally more robust but may be heavier.

Finish and Coating Options

Consider the finish and coating options available for corrugated aluminum sheets. Depending on the application, customers may opt for painted, anodized, or coated finishes for enhanced durability and aesthetics.

Related search about Corrugated Aluminum Sheet Plate

- corrugated aluminum roofing

- corrugated aluminum rv siding

- corrugated aluminum pipe

- corrugated aluminum camper siding

- corrugated aluminum panel

- corrugated aluminum sheeting

- corrugated aluminum fence

- corrugated aluminum sheet metal

People also Ask about Corrugated Aluminum Sheet Plate

- What does corrugated aluminum mean?

- What does corrugated aluminum look like?

- Does corrugated aluminum rust?

Conclusion

Corrugated aluminum sheet plates have proven to be a versatile and reliable material across various industries. Understanding the functions, advantages, considerations for purchase, alloy options, selection criteria, applications, specifications, and thickness options is crucial for making informed decisions.

Whether used in roofing, cladding, transportation, or decorative applications, corrugated aluminum sheets continue to be a go-to choice for projects that demand strength, durability, and corrosion resistance. By carefully considering the specific needs of each application, customers can harness the full potential of corrugated aluminum sheet plates in their projects.