- Why Use Aluminum Foil for Transformer Coil Winding?

- Properties of Aluminum Foil for Transformers

- Aluminum Foil For Transformer Winding Specifications

- Electrical conductivity of aluminum foils for transformers

- Advantages of Aluminum Foil in Transformer Coil Winding

- Aluminium Foil For Transformer Winding Alloy Selection

- Aluminum foil for transformer winding chemical composition

- How Aluminum Foils used in Transformer?

- Manufacturing Process

- Transformer Winding

- Why do we use an Aluminum Foil Strip for HV Transformer Winding?

- Frequently Asked Questions (FAQ) about Aluminum Foil for Transformer Winding

Aluminum foil plays a crucial role in the manufacturing of transformers, contributing significantly to their efficiency and performance.Transformers are essential components in the electrical power distribution system, responsible for transforming voltage levels for transmission and distribution.

Why Use Aluminum Foil for Transformer Coil Winding?

1. Advantages in Electrical Conductivity and Electrical Characteristics

Aluminum foil has excellent electrical conductivity, effectively transmitting electric current and reducing resistive losses.

This material helps to enhance the electrical efficiency of transformers, making energy conversion more efficient.

2. Lightweight and Size Optimization

Compared to traditional wires, aluminum foil is lighter, significantly reducing the overall weight of transformers when used.

Weight reduction lowers transportation and installation costs, while facilitating equipment mobility and maintenance.

3. Corrosion Resistance and Durability

Aluminum foil exhibits good corrosion resistance, maintaining its structure and performance over extended periods.

This property is crucial for transformers operating long-term and exposed to various environmental conditions, extending equipment lifespan.

4. Processability and Production Efficiency

Aluminum foil is soft and easy to process, suitable for complex transformer coil winding.

Using aluminum foil can simplify manufacturing processes, improve production efficiency, and reduce production costs.

5. High Temperature Operation and Reliability

Aluminum foil can operate stably at high temperatures, maintaining its electrical characteristics unaffected.

This capability enhances the reliability and stability of transformers under various operating conditions.

Properties of Aluminum Foil for Transformers

1. High Purity and Quality

Aluminum foil used in transformers is typically of high purity, often exceeding 99.5%. This ensures minimal impurities that could compromise the electrical properties of the foil.

2. Excellent Electrical Conductivity

Aluminum possesses excellent electrical conductivity, making it an ideal choice for transformer applications. High conductivity ensures efficient energy transfer within the transformer, minimizing energy losses.

3. Thermal Conductivity

Aluminum foil exhibits good thermal conductivity, aiding in the dissipation of heat generated during transformer operation. Efficient heat dissipation is crucial for maintaining the transformer's temperature within acceptable limits.

4. Formability and Flexibility

Aluminum foil is malleable and can be easily formed into the required shapes during the transformer winding process. Its flexibility allows for the creation of intricate winding patterns, optimizing the space within the transformer and enhancing its overall efficiency.

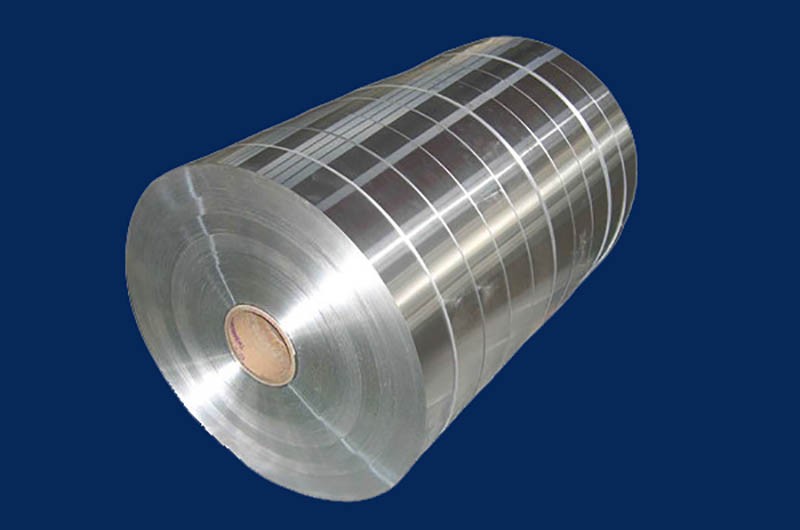

Aluminum Foil For Transformer Winding Specifications

| Product Name | Aluminum foil for transformer winding |

| Grades | 1050, 1350, 1060, 1070 |

| Temper | O |

| Thickness | 0.2mm-3.5mm |

| Width | Width:10mm-1600mm |

| Edge | Slit/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Treatment | The foil has a smooth surface, free from scratches and impurities |

| Electrical Conductivity | Transformer windings made of 1050 O in annealed condition is guaranteed to be better than 60 % ACS. Transformer windings made of 1060 O in annealed condition is guaranteed to be better than 61.5 % ACS. Transformer windings made of 1070 O in annealed condition is guar-anteed to be better than 62.7 % ACS. Transformer windings made of 1350 O in annealed condition is guaranteed to be better than 62 % ACS. |

| Applications | Transformer winding |

Electrical conductivity of aluminum foils for transformers

- 1050 is better than 60% IACS.

- 1060 is be better than 61.5% IACS.

- 1070 is better than 62.7% IACS.

- 1350 is better than 62% IACS.

Advantages of Aluminum Foil in Transformer Coil Winding

- Superior Processing Performance: Aluminum foil exhibits excellent processing capabilities, allowing it to be easily shaped into various complex cross-sectional forms as per user requirements. This flexibility enables precise adherence to design specifications during transformer production.

- High-Quality Surface: Aluminum foil maintains strict surface quality standards, ensuring uniform magnetic field distribution during transformer operation. This is crucial for reducing eddy current losses and improving transformer efficiency.

- Excellent Electrical and Thermal Conductivity: Aluminum foil possesses outstanding electrical and thermal conductivity, facilitating efficient current conduction and heat dissipation under normal operating conditions in transformers. This is essential for minimizing resistive losses and maintaining stable transformer operation.

- Good Magnetic Performance: Aluminum foil exhibits excellent magnetic properties, ensuring reliable transformer operation under various working conditions. It helps reduce hysteresis losses, thereby enhancing energy efficiency and performance stability.

- High Strength and Good Ductility: Aluminum foil offers high tensile strength and good elongation, allowing it to withstand complex operating environments and varying mechanical stresses within transformers. This ensures long-term reliability and durability of transformers.

Aluminium Foil For Transformer Winding Alloy Selection

Commonly used alloys include 1050, 1060, and 1070, known for their high electrical conductivity and formability.

1050 Aluminium Foil For Transformer Winding

1050 aluminum foil is one of the most commonly used materials in transformer winding due to its excellent performance. This foil exhibits outstanding thermal conductivity and electrical conductivity, typically used as a support material for transformer windings to significantly enhance performance and reduce energy losses.

During the manufacturing process of transformers, the thickness of 1050 aluminum foil usually ranges from 0.1mm to 3mm. To further reduce magnetic field leakage and enhance insulation performance, single-layer or double-layer structures of 1050 aluminum foil can be employed. This type of foil is specifically used to wrap coils, serving as connecting material for winding transformer coils.

- Electrical Conductivity: Transformer windings made of 1050 O in annealed condition is guaranteed to be better than 60 % ACS.

- Properties: High electrical conductivity, Good formability and weldability.

- Common Uses: Distribution transformers, Power transformers.

Examples:

Medium-sized distribution transformers used in local power distribution networks.

1060 Aluminium Foil For Transformer Winding

1060 aluminum foil is widely used in the winding of distribution and transmission transformers. It is suitable for both low-voltage and high-voltage electrical equipment. The demand for 1060 aluminum foil in the electrical equipment industry is high due to its excellent performance.

The 1060 aluminum coil used in transformer winding has a very high elongation rate, ensuring uniformity and strong crack resistance. Compared to other alloys, 1060 aluminum foil offers better flexibility, corrosion resistance, electrical conductivity, and thermal conductivity, albeit with slightly lower strength.

Additionally, 1060 aluminum foil boasts high mechanical strength, strong deformation resistance, high short-circuit withstand capability, high electrical strength, uniform impact gradient voltage distribution, and ease of winding.

- Electrical Conductivity: Transformer windings made of 1060 O in annealed condition is guaranteed to be better than 61.5 % ACS.

- Properties: Excellent electrical conductivity, Good corrosion resistance.

- Common Uses: Power transformers, Instrument transformers.

Examples:

Large power transformers used in high-voltage transmission networks.

Instrument transformers for measuring current and voltage in substations.

1070 Aluminium Foil For Transformer Winding

1070 aluminum is an industrial pure aluminum-based alloy known for its excellent thermal and electrical conductivity. This aluminum foil is primarily used in the winding of industrial transformers, as it is recyclable.

1070 transformer aluminum foil exhibits excellent formability, weldability, and corrosion resistance, meeting the performance standards required for transformer aluminum foil.

- Electrical Conductivity: Transformer windings made of 1070 O in annealed condition is guar-anteed to be better than 62.7 % ACS.

- Properties: High electrical conductivity, Good formability.

- Common Uses: Power transformers, Distribution transformers.

Examples:

Large power transformers used in grid substations.

Distribution transformers for supplying electricity to residential and industrial areas.

1350 O Aluminium Foil for Transformer Winding

1350 O is the optimal grade of aluminum foil used for oil-immersed distribution transformers and dry-type transformers.

Aluminum foils for transformer windings can be categorized into bare foils and coated foils. In oil-immersed transformers, bare wire types are commonly used for windings, while coated types are generally used for interlayer insulation.

- Electrical Conductivity: Transformer windings made of 1350 O in annealed condition is guaranteed to be better than 62 % ACS.

- Properties: High purity (99.5% or higher), Excellent electrical conductivity.

- Common Uses: High-voltage and extra-high-voltage transformers, Dry-type transformers.

Examples:

Extra-high-voltage transformers used in electricity transmission over long distances.

Dry-type transformers commonly found in indoor or sensitive environments.

Differences and Considerations

Purity: Alloy 1350 is known for its higher purity compared to the 1000 series alloys. This high purity is advantageous in applications where low levels of impurities are critical, such as in high-voltage and dry-type transformers.

Strength: Alloys 1050, 1060, and 1070 generally have higher strength compared to 1350. The choice of alloy may depend on the mechanical strength requirements of the specific transformer application.

Applications: Alloys 1050, 1060, and 1070 are commonly used in a wide range of transformers, including distribution and power transformers. Alloy 1350 is often chosen for applications where high purity is essential, such as in high-voltage and dry-type transformers.

Formability: Alloys 1050, 1060, and 1070 are known for their good formability, making them suitable for intricate winding patterns in transformer coils.

Corrosion Resistance: Alloy 1060 is known for its good corrosion resistance, which can be advantageous in environments where exposure to moisture is a concern.

The selection of a specific alloy depends on the transformer's design requirements, voltage class, and the desired balance of electrical, mechanical, and environmental properties.

Aluminum foil for transformer winding chemical composition

1050 O Aluminum Foil For Transformer Winding Chemical Composition(%)

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

1060 O Aluminum Foil For Transformer Winding Chemical Composition(%)

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

1070 O Aluminum Foil For Transformer Winding Chemical Composition(%)

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.7 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

1350 O Aluminum Foil For Transformer Winding Chemical Composition(%)

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0 |

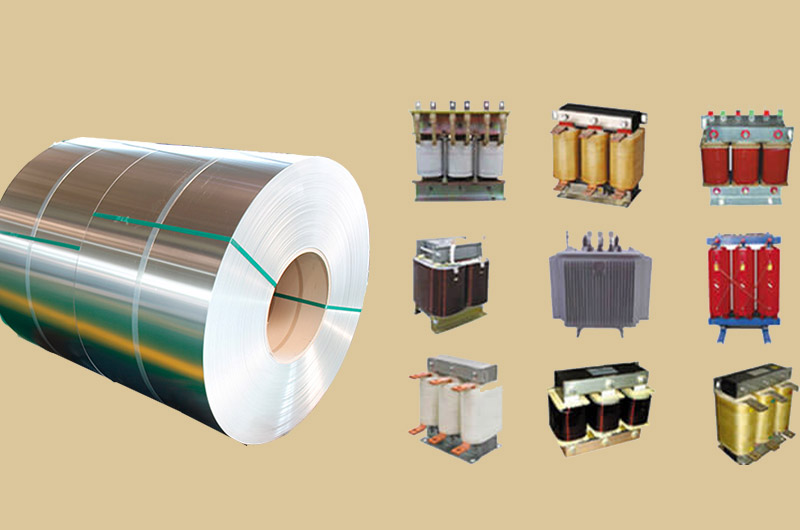

How Aluminum Foils used in Transformer?

In transformers, aluminum foil serves as an electrical insulator. Due to its low electrical resistance and good thermal conductivity, it is an ideal material for this purpose.

Transformer windings are essential components of transformers, consisting of winding wires and winding insulation.

The primary role of winding insulation is to establish insulation between the turns and the winding wires that carry the current.

Before being used in transformer winding, aluminum foil should undergo thorough cleaning to prevent dust from entering the foil after the winding process is completed.

Manufacturing Process

1. Casting and Rolling

The selected aluminum alloy undergoes a casting process to create large ingots. These ingots are then hot-rolled into thin sheets, which serve as the basis for the transformer foil.

2. Annealing

The rolled aluminum sheets undergo an annealing process to enhance their softness and conductivity. Annealing involves heating the material to a specific temperature and then slowly cooling it to achieve the desired properties.

3. Surface Treatment

The surface of the aluminum foil may undergo treatment processes such as chemical cleaning or anodizing to improve its insulation properties and resistance to environmental factors.

Transformer Winding

Layered Winding

Aluminum foil is used in the winding process of transformers, forming layers between the transformer's primary and secondary windings. The layered configuration helps optimize the magnetic flux and reduces losses.

Insulation

Insulating materials are often interleaved with the aluminum foil to prevent short circuits and ensure the reliable performance of the transformer.

Why do we use an Aluminum Foil Strip for HV Transformer Winding?

The aluminum foils strips are used for high-voltage transformer with thickness and width ranges from 0.1mm to 3.0mm, and 10mm to 1370mm, respectively.

Generally, tempered aluminum alloy is used for HV transformers like 1060 O and 1070 O.

High-grade insulating foils are placed between aluminum foil strips. Mostly 1060 and 1070 alloys of aluminum are used to wind the high-voltage transformer windings.

The relatively high windings exhibit good ageing qualities under all operating conditions and corrosion-proof. For HV transformer windings, an aluminum foil strip provides a basic winding method with high electrical safety.

Frequently Asked Questions (FAQ) about Aluminum Foil for Transformer Winding

1. Why is aluminum foil used in transformer winding?

Aluminum foil is used in transformer winding due to its high electrical conductivity, formability, and thermal conductivity. It serves as a conductor in the transformer windings, facilitating efficient energy transfer.

2. What thickness of aluminum foil is suitable for transformer winding?

The thickness of aluminum foil for transformer winding varies based on the specific requirements of the transformer. It is typically in the range of 10 to 20 microns, but thicker foils may be used for certain applications.

3. How is aluminum foil protected during transportation and storage?

Aluminum foil for transformer winding is often protected with appropriate packaging materials such as moisture-resistant films and cartons. These materials shield the foil from moisture, dust, and other environmental factors.

4. What are the insulation properties of aluminum foil for transformer winding?

Aluminum foil may undergo treatments or have coatings to enhance its insulation properties. This is crucial to prevent electrical breakdowns within the transformer and ensure safe and reliable operation.

5. Can aluminum foil be used in all types of transformers?

Aluminum foil is commonly used in various types of transformers, including distribution transformers, power transformers, and instrument transformers. The specific alloy and thickness may vary based on the transformer's design and application.

6. How is the formability of aluminum foil maintained during packaging?

Proper handling and packaging techniques are employed to maintain the formability of aluminum foil. Packaging materials are chosen to avoid any damage or deformities to the foil during transportation and storage.

7. Are there specific standards for aluminum foil used in transformer winding?

Yes, there are industry standards and specifications that define the requirements for aluminum foil used in transformer winding. Manufacturers adhere to these standards to ensure the quality and performance of the foil in transformers.

Aluminum foil is a fundamental component in the construction of transformers, contributing to their electrical and thermal performance. The careful selection of high-purity alloys, coupled with precise manufacturing processes, results in aluminum foil that meets the demanding requirements of the transformer industry.

As electrical systems evolve, the role of aluminum foil in transformers remains pivotal, enabling the efficient and reliable transmission of electrical power across the grid.