- PP Cap Aluminum Foil Composition and Manufacturing

- PP Cap Aluminum Foil Structural Composition

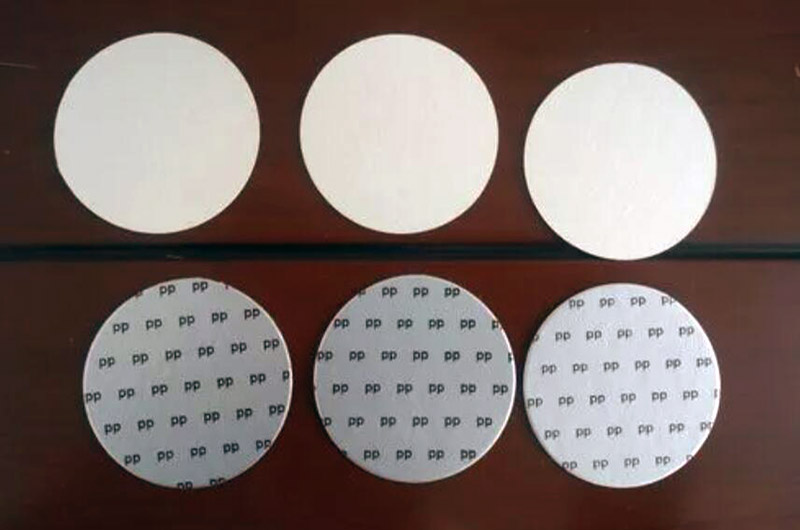

- PP Cap Aluminum Foil Features and Properties

- PP Cap Aluminum Foil Specifications

- PP Cap Aluminum Foil Applications

- FAQs (Frequently Asked Questions) about PP Cap Aluminum Foil

- Conclusion

In the realm of packaging materials, aluminum foil has emerged as a versatile and indispensable component, finding applications in various industries.Among its many applications, one noteworthy use is in the production of PP (Polypropylene) cap aluminum foil.

This specialized foil plays a crucial role in sealing and preserving the contents of containers, particularly in the food and beverage industry.

PP Cap Aluminum Foil Composition and Manufacturing

PP cap aluminum foil is typically a composite material, combining the properties of aluminum and polypropylene. The aluminum layer provides an excellent barrier against moisture, oxygen, and other environmental factors, while the polypropylene layer ensures the flexibility and heat-sealing capability of the foil.

The manufacturing process involves laminating these layers together to create a robust and efficient sealing material.

PP Cap Aluminum Foil Structural Composition

1. Aluminum Foil Layer

The primary component is a layer of aluminum foil. Aluminum is chosen for its excellent barrier properties against moisture, light, and gases. It helps in preserving the freshness and integrity of the packaged contents.

2. Adhesive Layer

An adhesive layer is applied to bond the aluminum foil to other layers. The adhesive used is typically chosen for its ability to securely bond with both the aluminum foil and the underlying polypropylene layer.

3. Polypropylene (PP) Layer

The polypropylene layer provides additional strength, flexibility, and heat resistance to the structure. Polypropylene is commonly used in packaging materials due to its excellent chemical resistance and high melting point.

4. Heat Seal Layer

A heat-sealable layer is often incorporated to enable the foil to be securely sealed to the container or packaging. This layer allows for a strong and reliable seal, ensuring the contents remain protected from external factors.

PP Cap Aluminum Foil Features and Properties

1. Sealing Performance

PP cap aluminum foil is known for its exceptional sealing performance. The foil forms a hermetic seal when applied to containers, preventing the ingress of air and moisture. This feature is particularly crucial in preserving the freshness and quality of perishable goods.

2. Flexibility

The polypropylene layer imparts flexibility to the foil, allowing it to conform to the contours of the container's opening. This flexibility ensures a secure and tight seal, even on irregularly shaped surfaces.

3. Heat Resistance

PP cap aluminum foil exhibits remarkable heat resistance, making it suitable for applications that involve heat sealing. This property ensures that the foil can withstand the heat-sealing process without compromising its integrity.

4. Printability

The surface of the foil is often designed to be printable, allowing manufacturers to incorporate branding, product information, and other relevant details directly onto the cap. This not only serves functional purposes but also contributes to the overall aesthetics of the packaging.

PP Cap Aluminum Foil Specifications

| Alloy | 8011, 3105, 1050, 1060 |

|---|---|

| Temper | O, H14 |

| Thickness | 0.06~0.2mm |

| Width | 200-600mm |

| Surface | mill finish, coated |

| Adhesion | EN, ASTM, JIS ISO9001 |

PP Cap Aluminum Foil Applications

8011 PP Cap Aluminum Foil for Beverage Packaging

PP cap aluminum foil is extensively used in the beverage industry for sealing bottles of various sizes. It ensures the integrity of the product by preventing contamination and maintaining carbonation levels in carbonated beverages.

- Aluminum Alloy: Typically, 8011 aluminum alloy is commonly used for beverage packaging. It offers a good balance of strength, formability, and barrier properties.

- Temper: H14 or H16 temper is commonly chosen for beverage packaging. These temper conditions provide the right combination of strength and formability.

- Thickness: The thickness of the foil for beverage packaging usually ranges from 0.018 to 0.022 mm, depending on the specific requirements of the application.

PP Cap Aluminum Foil for Pharmaceuticals Packaging

The pharmaceutical industry relies on the sealing capabilities of PP cap aluminum foil to protect drugs and medications from external factors that could compromise their efficacy. The foil provides a tamper-evident seal, assuring consumers of product safety.

- Aluminum Alloy: 8011 alloy is also commonly used in pharmaceutical packaging due to its excellent barrier properties and compatibility with the sealing process.

- Temper: H18 temper is often preferred for pharmaceutical applications. It provides high strength, making it suitable for protecting drugs and medications effectively.

- Thickness: The thickness for pharmaceutical packaging can range from 0.020 to 0.025 mm, depending on the specific needs and regulations.

PP Cap Aluminum Foil for Food Packaging

In the food industry, PP cap aluminum foil is widely employed for sealing jars, containers, and cans. It safeguards the contents from external influences while also serving as a barrier against light and odors.

- Aluminum Alloy: Similar to beverage packaging, 8011 alloy is commonly used for food packaging due to its suitability for direct contact with food.

- Temper: H14 or H16 temper is generally selected for food packaging applications, providing a good balance of strength and formability.

- Thickness: The thickness for food packaging can vary but often falls within the range of 0.018 to 0.025 mm.

PP Cap Aluminum Foil for Cosmetics and Personal Care

Manufacturers in the cosmetics and personal care industry utilize PP cap aluminum foil for sealing products like lotions, creams, and cosmetic containers. The foil aids in preserving the freshness and quality of these products.

- Aluminum Alloy: 8011 alloy is also suitable for cosmetics and personal care applications, ensuring compatibility with various formulations.

- Temper: H14 or H16 temper is commonly chosen for these applications to balance strength and formability.

- Thickness: The thickness for cosmetics and personal care packaging is often similar to that used in food packaging, ranging from 0.018 to 0.025 mm.

FAQs (Frequently Asked Questions) about PP Cap Aluminum Foil

What is the purpose of PP cap aluminum foil?

PP cap aluminum foil is used for sealing and protecting products, primarily in the pharmaceutical and food industries. It provides a barrier against moisture, light, and gases, preserving the quality and freshness of the packaged contents.

Why is aluminum chosen for the foil layer?

Aluminum is selected for its excellent barrier properties. It effectively blocks moisture, light, and gases, preventing the deterioration of the packaged contents. Additionally, aluminum is lightweight and can be easily shaped and sealed.

What is the role of polypropylene in the structure?

Polypropylene adds strength, flexibility, and heat resistance to the structure. It complements the barrier properties of aluminum and contributes to the overall durability of the packaging material.

How is PP cap aluminum foil sealed to containers?

PP cap aluminum foil is sealed to containers using a heat-sealable layer. This layer allows the foil to be securely bonded to the container when exposed to heat, ensuring a reliable seal.

Is PP cap aluminum foil recyclable?

The recyclability of PP cap aluminum foil depends on the specific composition and local recycling facilities. In many cases, aluminum is highly recyclable, but the presence of other layers, such as adhesives or coatings, may affect recyclability. It's essential to check with local recycling guidelines.

What is the purpose of the adhesive layer in the foil structure?

The adhesive layer bonds the aluminum and polypropylene layers together, ensuring a cohesive and durable composite structure.

Can PP cap aluminum foil be printed on?

Yes, many PP cap aluminum foils have a printable surface, allowing manufacturers to incorporate branding, product information, and other details directly onto the cap.

Conclusion

PP cap aluminum foil stands out as a vital component in modern packaging solutions, providing a reliable and efficient method for sealing containers across various industries.

Its combination of aluminum's protective properties and polypropylene's flexibility makes it an ideal choice for ensuring the longevity and quality of packaged products.

As technology continues to advance, it is likely that PP cap aluminum foil will see further innovations and applications, solidifying its role in the ever-evolving landscape of packaging materials.