- Important indicators of medicinal aluminum foil

- Commonly Used Medicinal Aluminum Foil

- 8011 vs 8021 Pharmaceutical Aluminum Foil

- Key Pharmaceutical Aluminum Foil Introduction

- What is the use of aluminum foil in pharmaceutical industry?

- What is The Thickness of Pharma Foil?

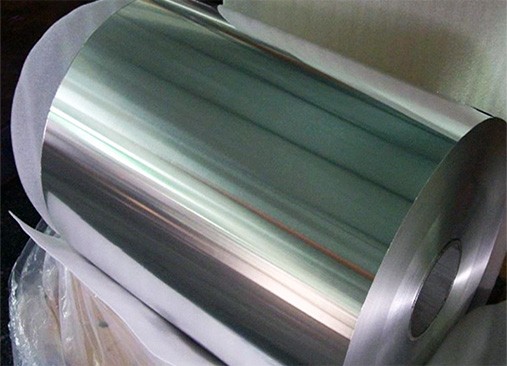

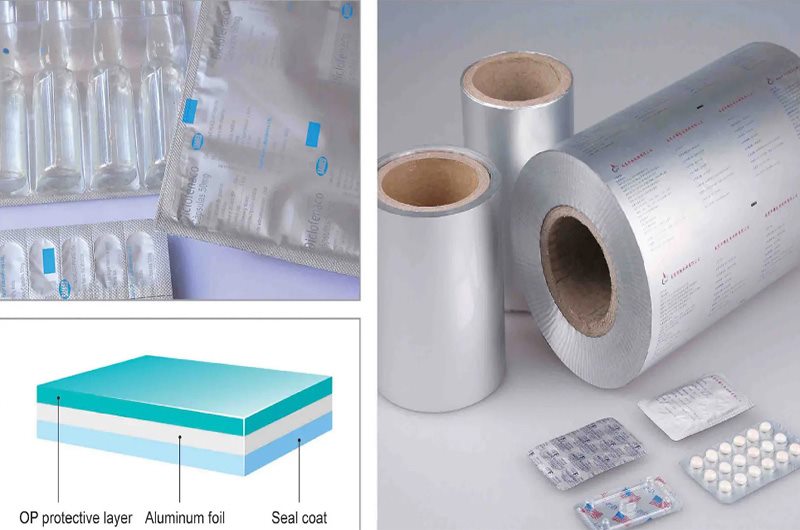

Pharmaceutical aluminum foil is a special packaging material for packaging solid, liquid and semi-solid dosage forms in the pharmaceutical industry. It is an aluminum foil specially designed for pharmaceutical packaging applications and must meet certain quality and performance standards to ensure the safety, effectiveness and stability of the packaged medicines.

Pharmaceutical aluminum foil is usually made of 8011 or 8021 aluminum alloy with a thickness ranging from 0.02mm to 0.07mm. The surface of pharmaceutical aluminum foil is usually coated with a layer of protective coating, such as heat-sealing varnish, which can improve its sealing and adhesion performance, and facilitate packaging sealing.

Pharmaceutical aluminum foil is widely used in the packaging of various dosage forms such as tablets, capsules, powders, granules, and suppositories. It is also used in the packaging of medical devices and instruments such as syringes, needles and catheters. Pharmaceutical products packaged in aluminum foil are often required to meet stringent quality standards, such as Good Manufacturing Practice (GMP) guidelines, to ensure the safety, efficacy and quality of pharmaceuticals.

Important indicators of medicinal aluminum foil

The surface of medicinal aluminum foil should be clean, flat, and evenly coated, and the text and pattern printing should be correct, clear, and firm.

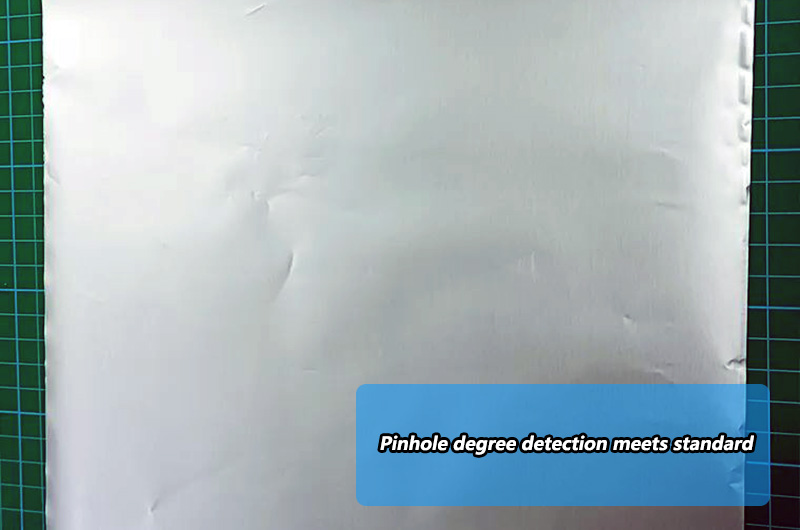

1. Pinhole degree

The rolling process is used in the aluminum foil production process, and defects will inevitably occur, and pinholes are the most important one.

The size and number of pinholes in aluminum foil have a decisive influence on the moisture resistance, gas barrier and light-shielding properties of aluminum foil and its composite materials. Aluminum foil should not have dense, continuous, periodic pinholes. In each square meter, no pinholes with a diameter greater than 0.3mm are allowed, and no more than one pinhole with a diameter of 0.1~0.3mm is allowed.

2. Barrier performance

Measuring the barrier performance indicators of pharmaceutical packaging materials:

Oxygen transmission rate

water vapor transmission rate

The barrier performance of aluminum foil is an important indicator for selecting suitable packaging materials for pharmaceutical products. Packaging containers with excellent barrier properties can prevent drugs from absorbing moisture and active ingredients from being oxidized and deteriorated, greatly extending the shelf life of drugs.

3. Bursting strength

The ability of aluminum foil to withstand static localized extrusion in actual transportation environments.

Pay attention to the process of pharmaceutical packaging molding, transportation, storage, and sales to protect the pharmaceuticals from damage caused by external pressure and impact.

4. Heat sealing strength of adhesive layer

The thermal bonding strength between the blister and the aluminum foil is directly related to heat sealing parameters such as heat sealing temperature, heat sealing pressure, and heat sealing time.

The heat sealing strength of blister and aluminum foil is low and leakage problems are prone to occur. This means that the protective function of the pharmaceutical packaging will be completely lost due to direct contact between the medicine and the outside air, which will bring great consequences to the producers and users of medicines. risks of.

5. Adhesion of protective layer

In addition to preventing oxidation and corrosion of the aluminum foil, the protective layer on the surface of the aluminum foil can also protect the printed layer on the surface of the aluminum foil from being scratched.

The adhesion of the protective layer is poor. When it falls off during heat sealing or other heating processes, the protective effect on the ink will be weakened, so the ink layer is prone to problems such as scratching and falling off.

6. Heat resistance of protective layer

The protective layer has poor heat resistance and is prone to falling off during heating processes such as the heat sealing process.

The protective layer is laminated with the original aluminum foil and heat-sealed at 200°C. After cooling, check whether the surface of the protective layer has obviously peeled off.

Commonly Used Medicinal Aluminum Foil

8011 O Pharmaceutical Aluminum Foil

8011 aluminum foil has become the first choice for medicinal aluminum foil due to its excellent performance.

- Application : 8011 pharmaceutical aluminum foil is usually used to make capsules, tablets, oral liquids, injections, external ointments, patches, etc. for pharmaceutical packaging. It can be used in the preparation of aluminum-plastic composite, PVC and other flexible packaging materials.

- Alloy state : The alloy state of 8011 pharmaceutical aluminum foil is usually O state (that is, soft).

- Application examples : berberine hydrochloride oral liquid, penicillin potassium injection, heparin sodium injection, etc.

8021 O Pharmaceutical Aluminum Foil

8021 pharmaceutical aluminum foil has better heat resistance at high temperature.

Application : 8021 pharmaceutical aluminum foil is mainly used to make capsules, tablets, oral liquids, injections, external ointments, patches, etc. for pharmaceutical packaging. It can also be used in the preparation of aluminum-plastic composite, PVC and other flexible packaging materials.

- Alloy state : The alloy state of 8021 medicinal aluminum foil is O state (that is, soft).

- Application examples : cefotaxime tablets, doxycycline injection, human albumin injection, etc.

8011 vs 8021 Pharmaceutical Aluminum Foil

- Alloy composition : The alloy composition of 8011 medicinal aluminum foil and 8021 medicinal aluminum foil is slightly different, and the copper content in 8021 medicinal aluminum foil is higher.

- Features : 8021 pharmaceutical aluminum foil has better heat resistance at high temperature, so 8021 pharmaceutical aluminum foil is usually selected in pharmaceutical packaging that requires high temperature sterilization or heat treatment. 8011 pharmaceutical aluminum foil is usually used for general pharmaceutical packaging.

- Price : Due to the higher copper content in 8021 medicinal aluminum foil, its price is usually higher than that of 8011 medicinal aluminum foil.

Key Pharmaceutical Aluminum Foil Introduction

Blister Aluminum Foil

Medicinal aluminum foil and plastic hard sheet (polyvinyl chloride PVC) are the main materials for blister packaging

- Typical Alloy: 8021 Aluminum Foil

- Material Status: O

- Thickness (mm): 0.04-0.065

- Width (mm): 200-1600

- Typical Products: Bubble cover packaging, etc.

Description: Utilizing the flexibility and plasticity of 8021 aluminum alloy in the O state, this foil is suitable for making bubble cover packaging. It provides effective isolation of moisture and oxygen, ensuring the long-term preservation of drugs.

Blister aluminum foil is a commonly used pharmaceutical packaging material, usually composed of aluminum foil and heat-sealing layer. Blister aluminum foil is commonly used to make tablet and capsule packaging for pharmaceuticals. It has good oxygen barrier, moisture proof, light proof, aroma proof, heat resistance and tear resistance.

Pharmaceutical ptp Aluminum Foil

Pharmaceutical PTP (Press Penetration Packaging) aluminum foil is a commonly used packaging material in the pharmaceutical industry for packaging solid dosage forms such as capsules and tablets. PTP aluminum foil is made of aluminum and designed to protect against moisture, oxygen and other environmental factors that can degrade product quality.

- Typical Alloy: 8011 Aluminum Foil

- Material Status: H18

- Thickness (mm): 0.016-0.5

- Width (mm): 200-1600

- Typical Products: Capsule medicine blister covers, etc.

Description: Used for packaging capsule medications, the H18 state of 8011 aluminum foil provides high strength and heat resistance. Its superior light and moisture barrier properties effectively protect drugs from humidity and external contaminants.

PTP aluminum foil is usually laminated with a heat-sealable polymer on one side and a layer of PVC, PVDC or other material on the other side. This allows the foil to be sealed to form an airtight and tamper-resistant blister pack.

Cold-form Aluminum Foil

Cold-formed aluminum foil is a packaging material used in the pharmaceutical industry for packaging solid dosage forms such as tablets and capsules. It is called "cold forming" because it is formed at room temperature, unlike blister foil, which is formed by heat.

Tropical Blister Aluminum Foil

Tropical blister foil is a packaging material used in the pharmaceutical industry for packaging solid dosage forms such as tablets and capsules in hot and humid climates. It is called "tropical" because it is designed to provide an effective barrier against moisture and other environmental elements common in tropical and humid regions.

- Typical Alloys: 8021 Aluminum Foil, 8079 Aluminum Foil

- Material Status: O

- Thickness (mm): 0.016-0.2

- Width (mm): 200-1600

- Typical Products: High-end pharmaceutical packaging

Description: Often made from 8021 or 8079 aluminum alloy in the O state, this type of foil is used for high-end pharmaceutical packaging. Its thin thickness and excellent antioxidant properties make it an ideal choice for demanding pharmaceutical applications.

Tropical blister foil usually forms individual cavities, each containing a single dose of medication. The cavity is then sealed with a heat-sealable backing material, usually made of the same polymer material as the laminate layers.

Aluminum Foil for Medicinal Caps

- Typical Alloy: 8011 Aluminum Foil

- Material Status: H14, H16

- Thickness (mm): 0.016-0.5

- Width (mm): 200-1600

- Typical Products: Aluminum-plastic composite caps for oral liquids, aluminum-plastic caps for infusion bottles, etc.

Description: Utilizing 8011 aluminum alloy in H14 or H16 states ensures optimal sealing and strength for applications like aluminum-plastic composite caps for oral liquids and aluminum-plastic caps for infusion bottles.

Medicinal Aluminum Foil Gaskets

- Typical Alloy: 1060 Aluminum Foil

- Material Status: O, H18

- Thickness (mm): 0.014-0.2

- Width (mm): 200-1600

- Typical Products: Medicinal packaging gaskets

Description: Commonly made from 1060 aluminum alloy, these foil gaskets can be in O or H18 states. They are used for pharmaceutical packaging, providing good adaptability during the packaging process due to their thin and flexible nature.

What is the use of aluminum foil in pharmaceutical industry?

Aluminum foil is widely used in the pharmaceutical industry for the packaging and protection of pharmaceuticals and medical devices. Some common uses of aluminum foil in the pharmaceutical industry include:

- Primary Packaging : Aluminum foil is used for packaging various solid, semi-solid and liquid dosage forms such as tablets, capsules, powders, creams, ointments and liquids. The foil provides an excellent barrier against moisture, light, oxygen and other gases that can reduce or alter the efficacy of the drug.

- Secondary packaging : Aluminum foil is used as secondary packaging material for primary packaging, such as blister packaging, pouches, etc. The foil provides additional protection and increases the overall stability and shelf life of the drug.

- Medical Devices : Aluminum foil is used to package and protect various medical devices such as syringes, needles and catheters. Aluminum foil provides a sterile barrier that prevents contamination and ensures device safety and effectiveness.

- Labeling and printing : Aluminum foil can be printed in a variety of colors and designs to create attractive and informative labels for the packaging of pharmaceuticals and medical devices.

What is The Thickness of Pharma Foil?

The thickness of pharmaceutical aluminum foil can vary depending on the specific application and the requirements of the drug or medical device being packaged. However, the thickness of pharmaceutical grade aluminum foil is usually between 0.02mm and 0.08mm.

- The thickness of aluminum foil used for blister packaging of tablets and capsules is usually 0.02 mm - 0.04 mm.

- The thickness of aluminum foil used for powder and granule sachet packaging is usually 0.04mm - 0.08mm.

The thickness of aluminum foil used for tablet stick packaging is usually between 0.02mm and 0.03mm.

The thickness of pharmaceutical aluminum foil is an important factor in determining its barrier properties and performance.

- Thicker foils generally provide better barrier properties

- Thinner foils are more flexible and easier to handle.

The exact thickness of aluminum foil for a particular application will depend on factors such as the type of drug or medical device being packaged, shelf life requirements, and packaging regulations and standards.