- What is Hydrophobic Aluminum Foil?

- Why Choose Hydrophobic Aluminum Foil?

- Hydrophobic Aluminum Foil Specifications

- Color Options for Hydrophobic Aluminum Foil Coatings

- Hydrophobic Aluminum Foil Functional Features

- Hydrophobic coated Aluminium Foil Technical Information

- Differences Between Hydrophobic Aluminum Foil and Hydrophilic Aluminum Foil

- Applications of Hydrophobic Aluminum Foil

- Frequently Asked Questions about Hydrophobic Aluminum Foil

What is Hydrophobic Aluminum Foil?

Hydrophobic foil is an aluminum foil product used in air conditioning fins, coated with a hydrophobic layer on the surface.

The ultimate goal of hydrophobic aluminum foil is to ensure condensate does not accumulate between fins, by increasing the contact angle, allowing condensate to form droplets that slide off naturally.

Hydrophobic aluminum foil prevents water from adhering to the surface, forming droplets that easily roll off.

Why Choose Hydrophobic Aluminum Foil?

Choosing hydrophobic aluminum foil aims to prolong the lifespan of air conditioners, reduce power consumption, improve ventilation quality, and enhance cooling efficiency, thus various functional coated heat exchanger fins have been developed.

Research has shown that in heat exchangers, condensed water droplets easily form "water bridges, " affecting heat exchange efficiency and increasing noise pollution.

Currently, an effective solution is to apply a water-conductive coating on the aluminum foil to facilitate the self-removal of water droplets.

Methods to impart water conductivity to aluminum foil include hydrophilic and hydrophobic treatments.

Studies indicate that under humid conditions, corrugated fins with hydrophilic layers perform better in heat exchange efficiency compared to those without, and they also excel under dry conditions.

When using hydrophobic foil, its heat exchange efficiency is similar to dry conditions, slightly inferior to hydrophilic foil heat exchangers.

Hydrophilic foil performs better in enhancing heat exchange efficiency, while hydrophobic foil is more suitable for applications in dry environmental conditions.

Hydrophobic Aluminum Foil Specifications

Alloy Selection

- 1070 Aluminum Foil: Mainly composed of pure aluminum, with good conductivity and processability, suitable for general applications.

- 3003 Aluminum Foil: Contains more manganese, enhancing strength and corrosion resistance, often used in environments requiring higher mechanical performance.

- 8011 Aluminum Foil: Contains alloy elements like iron and silicon, with excellent corrosion resistance and processing properties, commonly used in special applications.

Temper

- H22: Partially hardened, with higher strength, suitable for applications with general strength requirements.

- H24: Slightly harder than H22, suitable for applications requiring higher strength and corrosion resistance.

- H26: Fully hardened, with the highest strength, suitable for special applications requiring extremely high mechanical performance.

Size Range

- Thickness: Typically between 0.09mm to 0.2mm, can be selected according to specific requirements.

- Width: Generally ranging from 100mm to 1300mm, catering to various manufacturing and installation needs.

Core Inner Diameter

The selectable core inner diameters are 76mm or 152mm, considering convenience for rolling and transportation.

Color Options for Hydrophobic Aluminum Foil Coatings

- Ordinary Hydrophobic Aluminum Foil: Typically the most basic choice, suitable for general applications.

- Gold Hydrophobic Aluminum Foil: Offers high visual appeal, ideal for projects requiring a more refined appearance.

- Blue Hydrophobic Aluminum Foil: Possibly used for specific branding or identification purposes, suitable for applications needing differentiation.

- Black Hydrophobic Aluminum Foil: Commonly used in environments with stricter requirements or needing greater solar absorption.

By selecting hydrophobic aluminum foil with different colors and coating properties, optimal performance and visual effects can be achieved based on specific project requirements and environmental conditions.

Hydrophobic Aluminum Foil Functional Features

- Enhanced Thermal Conductivity: Hydrophobic coatings on aluminum foil improve thermal conductivity, contributing to increased efficiency of heat exchangers compared to regular aluminum foil.

- Improved Corrosion Resistance: Hydrophobic coatings enhance aluminum foil's corrosion resistance by at least 300%, thereby increasing material durability and lifespan.

- Suitable for High-Efficiency Heat Exchangers: These features make hydrophobic coated aluminum foil an ideal choice for projects requiring the production of high-efficiency heat exchangers, capable of meeting rigorous operational environments and performance requirements.

Hydrophobic coated Aluminium Foil Technical Information

| Thickness | Width | Internal Diameter | External Diameter | Alloy |

| 0.08mm - 0.50mm | 40mm-1400mm | 75mm, 150mm, 200mm, 300mm | 100mm - 1400mm | 1050, 1100, 1200, 3102, 8006, 8011 |

8011 Grade Hydrophobic coated Aluminium Foil Technical Information

| Temper | ‘O’ – soft | H22 | H24 | H18 |

| Tensile strength | 80-110 MPA | 100-130 MPA | 115-145 MPA | ≥160 MPA |

| Yield strength | ≥50 MPA | ≥65 MPA | ≥90 MPA | / |

| Elongation | ≥20% | ≥16% | ≥12% | ≥1% |

8006 Grade Hydrophobic coated Aluminium Foil Technical Information

| Temper | ‘O’ – soft | H18 |

| Tensile strength | 90-140 MPA | ≥170 MPA |

Differences Between Hydrophobic Aluminum Foil and Hydrophilic Aluminum Foil

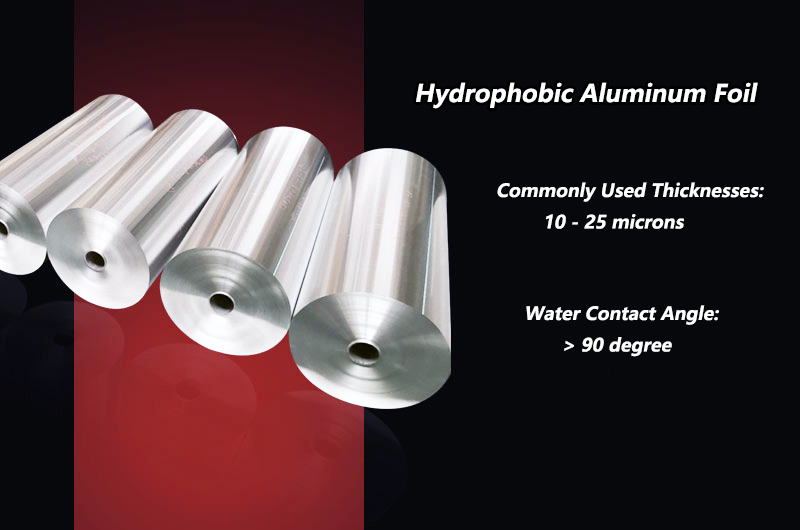

- Hydrophobic Aluminum Foil: Surface treated to form a hydrophobic layer, typically with a contact angle greater than 75 degrees, even up to over 130 degrees. This high contact angle provides excellent water repellency, making it resistant to water absorption.

- Hydrophilic Aluminum Foil: Designed to absorb moisture, characterized by a lower contact angle, suitable for applications requiring water absorption or retention.

The preparation method for hydrophobic aluminum foil may include adding dispersing particles to increase surface roughness, further enhancing hydrophobic properties and contact angle, thereby improving its waterproof characteristics and stability.

The choice between hydrophobic and hydrophilic aluminum foil depends on specific product requirements, including the need to maintain dry or moist conditions, and requirements for moisture resistance and waterproofing.

Applications of Hydrophobic Aluminum Foil

- 1. Packaging Field: Electronic products

- 2. Heat Dissipation Field: Air conditioners, automotive radiators

Hydrophobic foil requires a process of hydrophobic treatment and coating performance, with simple equipment and processes. A single rolling application achieves excellent corrosion resistance and high hydrophobicity, making it suitable for household air conditioner aluminum foil.

Frequently Asked Questions about Hydrophobic Aluminum Foil

1. How does Hydrophobic Aluminum Foil work?

The hydrophobic coating on the foil alters the surface tension of water, causing it to bead up and roll off rather than being absorbed. This property makes the foil resistant to moisture and enhances its performance in various applications.

2. What are the common alloys used in Hydrophobic Aluminum Foil?

Commonly used alloys include 8011, 3003, and 1235. These alloys are chosen for their balance of properties such as flexibility, strength, and corrosion resistance.

3. What temperatures can Hydrophobic Aluminum Foil withstand?

Hydrophobic Aluminum Foil is designed to withstand a broad range of temperatures, typically ranging from -40°C to 300°C. This makes it suitable for both cold and hot applications.

4. What are the thickness options for Hydrophobic Aluminum Foil?

Hydrophobic Aluminum Foil is available in various thicknesses, commonly ranging from 10 to 25 microns. The choice of thickness depends on the specific application and desired durability.

5. Can Hydrophobic Aluminum Foil be used for cooking and grilling?

Yes, Hydrophobic Aluminum Foil is suitable for cooking and grilling applications. Its water-repellent properties prevent the foil from absorbing liquids, making it efficient for wrapping and cooking various foods.

6. Is Hydrophobic Aluminum Foil recyclable?

Yes, Hydrophobic Aluminum Foil is recyclable. The base material, aluminum, is highly recyclable, contributing to eco-friendly practices in packaging and other applications.

7. What are the applications of Hydrophobic Aluminum Foil in the electronics industry?

Hydrophobic Aluminum Foil is used in the electronics industry to protect sensitive components from moisture during shipping and storage. It serves as a barrier to prevent water damage to electronic devices.

8. How does Hydrophobic Aluminum Foil contribute to sustainable packaging?

By extending the shelf life of food items and reducing food waste, Hydrophobic Aluminum Foil contributes to sustainable packaging. Its recyclability further aligns with environmentally friendly packaging practices.

9. Can Hydrophobic Aluminum Foil be used in outdoor applications?

Yes, Hydrophobic Aluminum Foil is suitable for outdoor applications. It is used in outdoor signage and displays to prevent water damage to printed materials, extending the life of graphics.

10. In which industries is Hydrophobic Aluminum Foil commonly used?

Hydrophobic Aluminum Foil finds applications in the food industry, electronics, scientific research, agriculture, automotive, and more. Its versatile properties make it suitable for a wide range of industries and applications.