- Learn about Condenser Fins

- Aluminum Foil Roll for Condenser Fins Specifications

- The importance of Aluminum Foil in Condenser Fins

- Manufacturing Process of Aluminum Foil for Condenser Fins

- Case studies and Practical Applications

- Conclusion

Aluminum foil is a versatile material with applications in a variety of industries. One of its key functions is to improve condenser fin efficiency.

Condensers are integral components in refrigeration, air conditioning and heat exchange systems and play a key role in heat transfer.

Learn about Condenser Fins

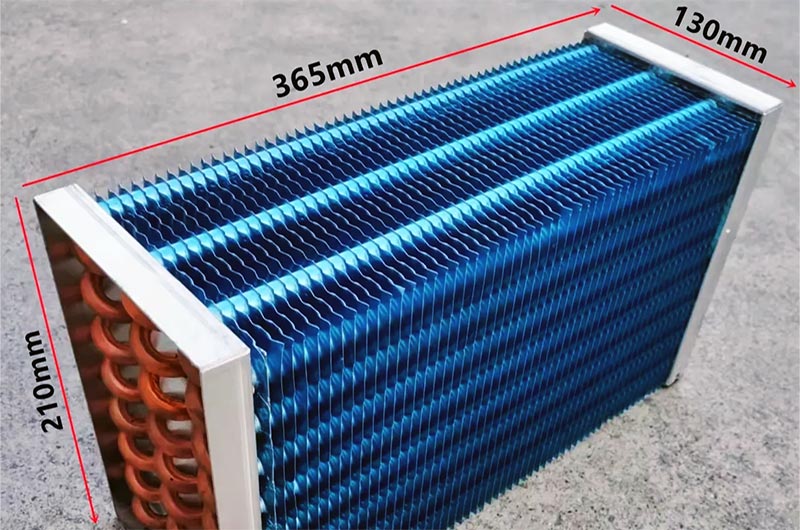

Condenser fins are thin, flat, parallel structures attached to the tubes or pipes in the condenser. They play a key role in promoting efficient heat transfer between the refrigerant and the surrounding air.

Fins increase the surface area available for heat exchange, allowing for better heat dissipation and improved system performance.

Aluminum Foil Roll for Condenser Fins Specifications

The specific alloy and specifications of aluminum fins used in condenser systems may vary depending on the application, environmental conditions and performance requirements. However, a commonly used alloy for condenser fins is aluminum alloy 1100.

Aluminum alloy 1100

Composition:

- Aluminum: minimum 99.0%

- Copper: 0.05%-0.20%

- Iron: 0.0%-0.95%

- Silicon: 0.0%-0.95%

- Manganese: 0.0%-0.05%

characteristic:

- Excellent corrosion resistance

- High thermal conductivity

- Good formability and processability

- Less strong than other alloys but suitable for fin applications

Aluminum condenser fin specifications

thickness:

The thickness of the aluminum fins can vary depending on the condenser design and performance requirements. Common thicknesses for condenser fins range from 0.1 mm to 0.3 mm.

Width and length:

The width and length of the fins are designed to optimize the surface area for heat exchange. Standard width and length are determined based on the size of the condenser and the required heat transfer efficiency.

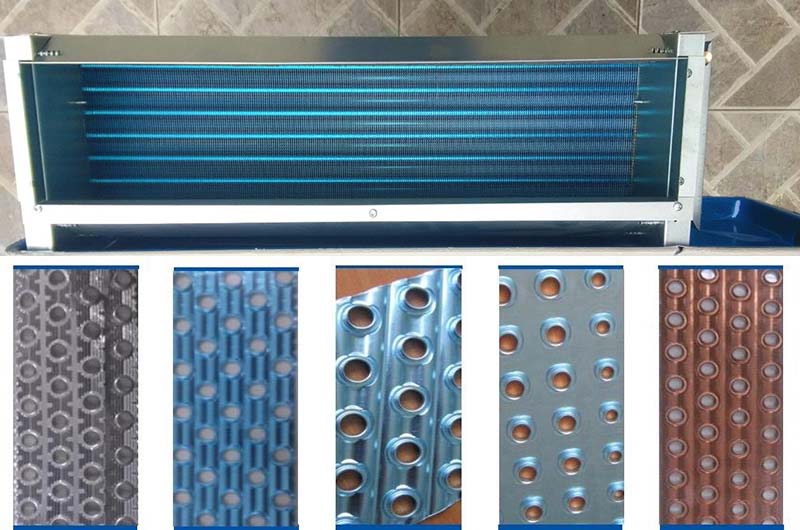

Surface treatment:

Depending on the environmental conditions the condenser is exposed to, the aluminum fins may be surface treated to increase corrosion resistance. This can include coating or anodizing processes.

temper:

Tempering of aluminum, whether annealed or under specific heat treatment conditions, affects the flexibility and formability of the fins. This is important to ensure that the fins can be easily formed and connected to the tubes or pipes in the condenser.

Other alloy options:

Although aluminum alloy 1100 is commonly used, certain applications may require alloys with specific properties. for example, alloys with higher copper content, such as 3003 or 3102, can be chosen for their improved strength and heat transfer capabilities.

Aluminum alloy 3003

- Contains a higher proportion of copper (0.05%-0.20%)

- Higher strength compared to 1100

- Good corrosion resistance and formability

Aluminum alloy 3102

- Higher copper content than 3003

- Improved strength and corrosion resistance

- Suitable for applications with high mechanical requirements

The importance of Aluminum Foil in Condenser Fins

1. Enhance heat transfer

Aluminum's high thermal conductivity ensures efficient heat transfer between the refrigerant and the surrounding air. This allows for a more efficient cooling process and increases overall system efficiency.

2. Improve durability

The corrosion resistance of aluminum foil contributes to the durability of the condenser fins, extending the life of the entire condenser unit. This is particularly important in applications where the condenser is exposed to different environmental conditions.

3. Energy efficiency

Aluminum foil's ability to reflect radiant heat helps improve the energy efficiency of air conditioning and refrigeration systems. By minimizing heat gain, the system can require less energy to maintain the desired temperature.

4. Cost-effective manufacturing

The lightweight nature of aluminum foil makes it a cost-effective material for shipping and handling during manufacturing. In addition, aluminum’s recyclability further adds to its economic advantages.

Manufacturing Process of Aluminum Foil for Condenser Fins

The production of aluminum foil for condenser fins involves several key manufacturing processes:

1. Scroll

The first step is to roll the aluminum ingot into thin sheets. The thickness of these sheets can be precisely controlled to meet the specific requirements of the condenser fins.

2. Annealing

Annealing is a heat treatment process that improves the flexibility and ductility of aluminum foil. This step is critical to ensure that the foil easily conforms to the shape of the condenser fins.

3. Surface treatment

Surface treatments can be performed to enhance the corrosion resistance of aluminum foil. These treatments can include coatings or anodizing processes to provide additional protection in harsh environments.

4. Slitting and cutting

The foil is then cut open and cut to size to apply to the condenser fins. Cutting precision is critical to achieving the required surface area and maximizing heat exchange efficiency.

Case studies and Practical Applications

Aluminum Fins For Condenser Car Air Conditioning System

Aluminum foil is widely used in automotive air conditioning condenser fins to ensure efficient heat dissipation in confined spaces. This application is critical to maintaining passenger comfort and optimal performance of the vehicle's cooling system.

alloy:

- Recommendation: Aluminum alloy 1100 or alloy 3003.

- Rationale: These alloys offer a good balance between thermal conductivity, formability and corrosion resistance. Alloy 3003 has a slightly higher copper content, which provides greater strength.

coating:

- Recommendation: Corrosion-resistant coatings such as epoxy or hydrophilic coatings.

- Rationale: Automotive air conditioning systems may be exposed to varying environmental conditions. Corrosion-resistant coatings protect aluminum fins from moisture, salt and other corrosive elements.

thickness:

- Recommended: 0.15mm to 0.20mm.

- Rationale: The limited space in automotive air conditioning systems requires thinner fins to maximize surface area for efficient heat dissipation while maintaining flexibility for easy molding.

Aluminum Fins For Condenser Refrigeration unit

In commercial and residential refrigeration units, the aluminum foil in the condenser fins plays a vital role in maintaining low temperatures. The efficiency of the condenser helps save energy and extend the life of the refrigeration system.

alloy:

- Recommendation: Aluminum alloy 1100 or alloy 3003.

- Rationale: Similar to automotive air conditioning systems, these alloys provide a good balance of properties for refrigeration applications.

coating:

- Recommendation: Corrosion-resistant coating such as epoxy or anti-corrosion treatment.

- Rationale: Refrigeration units are frequently exposed to moisture and changing temperatures. Under such conditions, a corrosion-resistant coating will extend the service life of the fins.

thickness:

- Recommended: 0.15mm to 0.25mm.

- Rationale: Refrigeration units may have larger fins to handle higher heat loads. Slightly thicker fins provide the necessary strength and heat dissipation capabilities.

Aluminum Fins For Condenser Industrial heat exchanger

Large industrial heat exchangers utilize aluminum foil reinforced condenser fins to effectively manage high heat loads. Industries such as power generation, chemical processing and manufacturing rely on these systems for effective thermal management.

alloy:

- Recommendation: Aluminum alloy 3003 or alloy 6061.

- Rationale: Alloy 6061’s increased strength makes it suitable for use in large industrial heat exchangers that handle high heat loads in demanding industrial environments.

coating:

- Recommendation: Corrosion-resistant coatings such as epoxy or special coatings for industrial applications.

- Rationale: Industrial environments may expose heat exchangers to corrosive chemicals or extreme conditions. Special coatings can provide enhanced protection.

thickness:

- Recommended: 0.25mm to 0.35mm.

- Rationale: Larger industrial heat exchangers may require thicker fins to handle higher heat loads and provide structural integrity.

Conclusion

The role of aluminum foil in increasing condenser fin efficiency demonstrates the material's superior performance and adaptability.

As technology advances and the need for energy-efficient solutions grows, the integration of aluminum foil in condenser fins is likely to continue to play a key role in shaping the future of heat exchange systems.

By addressing challenges, exploring innovative solutions and prioritizing sustainability, the industry can further unlock the full potential of aluminum foil in optimizing thermal management across a variety of applications.