- What is aluminium fin stock?

- Why is aluminium used as a fin material?

- Aluminum Fin Stock Material Properties

- Aluminum Fin Stock Specifications

- Chemical Composition of Different Alloy Aluminum Fin Stock

- Types of Aluminum fin stock

- Applications of Aluminum Fins

- Aluminum Fin Stock Manufacturer

What is aluminium fin stock?

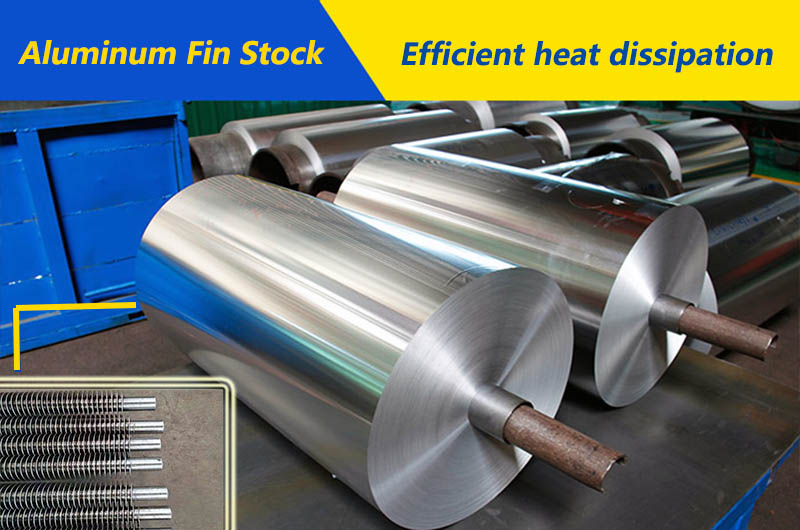

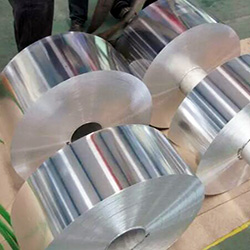

Aluminium fin stock refers to thin aluminium sheets or coils used in the production of heat exchanger fins. This material finds application in various uses including automotive radiators, heat shields, and a variety of heating, ventilation, and air conditioning (HVAC) components such as aluminium radiators, evaporators, and condensers.

The fin stock itself possesses good thermal conductivity and corrosion resistance, making it suitable for use under different temperature and humidity levels. Fins are formed from the fin stock through processes like stamping or rolling, depending on the specific design requirements of the heat exchanger.

Aluminium fin stock plays a crucial role in enhancing the efficiency and durability of heat exchangers by providing an optimal heat transfer surface while maintaining long-term structural integrity.

Why is aluminium used as a fin material?

- High Thermal Conductivity: Aluminium has excellent thermal conductivity, meaning it can effectively transfer heat from one medium (such as air or water) to another. This property helps to enhance the overall efficiency of heat exchangers by facilitating rapid heat exchange.

- Lightweight: Aluminium is lightweight compared to many other metals, which makes it easier to handle during manufacturing, reduces the weight of the heat exchanger itself, and contributes to energy savings in applications where weight is a critical factor, such as automotive and aerospace.

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer on its surface, providing resistance to corrosion. This is particularly important in environments where the heat exchanger may be exposed to moisture or other corrosive elements, such as in air conditioning units or marine applications.

- Ease of Manufacture: Aluminium is relatively easy to process using common manufacturing techniques like stamping, rolling, and welding. This allows manufacturers to efficiently and economically produce complex fin designs.

- Cost-Effectiveness: Aluminium is typically more cost-effective than other metals such as copper or stainless steel, making it a preferred choice for applications where cost considerations are important without compromising performance.

- Recyclability: Aluminium is highly recyclable, aligning with sustainability goals and reducing environmental impact compared to non-recyclable materials.

Aluminum fins are a lightweight, formable and corrosion-resistant material used in everything from car radiators to heat shields. It can also be used in a variety of heating, ventilation and air conditioning (HVAC) equipment such as aluminum radiators, aluminum evaporators and aluminum condensers.

Aluminum Fin Stock Material Properties

1. Thermal Conductivity: Aluminum is chosen for fin construction due to its excellent thermal conductivity. The ability to efficiently transfer heat from the source to the fins is crucial for the overall effectiveness of the heat dissipation process.

2. Lightweight Nature: Aluminum's lightweight nature makes it a practical choice for applications where weight is a consideration, such as in the aerospace and automotive industries.

Aluminum Fin Stock Specifications

Aluminum fin is a lightweight, formable and corrosion-resistant aluminum alloy material. It is usually made by rolling aluminum foil using 1000, 3000 and 8000 series aluminum alloy metal multiple times through an aluminum foil rolling mill to form a thin and flat Metal plate. These sheets usually come in the form of aluminum coils, but can also be cut into aluminum strips.

| Alloy | 1100 1200 3102 8011 8006 |

|---|---|

| Temper | O H22 H24 H26 H18 |

| Thickness(mm) | 0.08-0.2 (+/-5%) |

| Width (mm) | 100-1400 (+/-1) |

| I.D.(mm) | I.D.75/150/ 200/300/505 |

| Alloy | Temper | Mechanical Properties | ||

| Tensile Strength (Mpa) | Elongation(%) | Erichson (IE, mm | ||

| 1100 1200 3102 8011 8006 | O | 80-110 | ≥27 | ≥6.0 |

| H22 | 100-135 | ≥22 | ≥5.5 | |

| H24 | 115-145 | ≥20 | ≥5.0 | |

| H26 | 125-160 | ≥10 | ≥4.5 | |

| H18 | ≥160 | ≥1 | – | |

Special specifications can be produced as per customer’s requirements

Chemical Composition of Different Alloy Aluminum Fin Stock

| Alloy (%) | AA1050 | AA1100 | AA1200 | AA3003 | AA8006 | AA8011 |

|---|---|---|---|---|---|---|

| Fe | 0.40 | 0.95 | 1.00 | 0.70 | 1.40 — 1.60 | 0.6 — 1.00 |

| Si | 0.25 | (Fe + Si) | (Fe + Si) | 0.60 | 0.02 | 0.5 — 0.90 |

| Mg | 0.05 | – | – | – | 0.02 | 0.05 |

| Mn | 0.05 | 0.05 | 0.05 | 1.0 — 1.50 | 0.4 — 0.50 | 0.20 |

| Cu | 0.05 | 0.05 — 0.20 | 0.05 | 0.05 — 0.20 | 0.05 | 0.10 |

| Zn | 0.05 | 0.10 | 0.10 | 0.10 | 0.05 | 0.10 |

| Ti | 0.03 | – | 0.05 | 0.1(Ti+Zr) | 0.03 | 0.08 |

| Cr | – | – | – | – | – | 0.05 |

| Each(Others) | 0.03 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Total (Others) | – | 0.15 | 0.125 | 0.15 | 0.15 | 0.15 |

| Al | 99.50 | 99.00 | 99.00 | Remainder | Remainder | Remainder |

Types of Aluminum fin stock

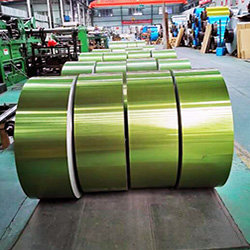

Coated Aluminum Fin Stock

Coated aluminum fins have excellent brazeability, resistance to core dissolution and high temperature collapse, making the heat exchanger lighter.

Uncoated Aluminum Fin Stock

Uncoated Aluminum Fin Stock is the most basic heat exchanger material. It consists only of the core layer without any coating. It can be used in a variety of applications including automotive radiators, intercoolers, oil coolers, evaporators, water tanks, heaters, and various air conditioning radiators.

- Bare (Uncoated) Aluminum Fin Stock

- Pre-coated Aluminum Fin Stock

- Hydrophilic Aluminum Fin Stock

- Corrosion-Resistant Aluminum Fin Stock

- Superhydrophobic Aluminum Fin Stock

- Self-Lubricating Aluminum Fin Stock

- Anti-Mildew Aluminum Fin Stock

-

Bare Aluminum Fin Stock

Bare Aluminum Fin Stock is used in a variety of automotive radiators, heat shields, and heating, ventilation and air conditioning applications. Fin blanks are mainly made of 1000, 3000 and 8000 series aluminum alloys.

-

Pre-coated Aluminum Fin Stock

The surface of pre-coated foils has been treated to provide more functionality than uncoated foils. Many of the corrosion-resistant aluminum foils and hydrophilic aluminum foils mentioned below can be classified as pre-coated aluminum foils.

-

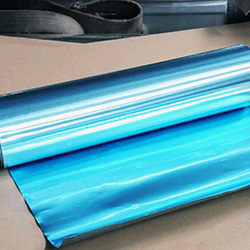

Hydrophilic Aluminum Fin Stock

Hydrophilic Aluminum Fin Stock is a hydrophilic treatment of aluminum foil. It is coated with a hydrophilic layer on its surface through a special process. The condensed water in the hydrophilic aluminum foil will spread quickly without condensing into water droplets. This not only increases the heat exchange area and speeds up the cooling and heating speed, but also effectively avoids water condensation caused by air flow noise.

-

Corrosion-Resistant Aluminum Fin Stock

This type of fin material is designed to resist corrosion, which is critical in applications where the fin surface is exposed to harsh environmental conditions or corrosive substances.

-

Superhydrophobic Aluminum Fin Stock

Superhydrophobic materials are extremely waterproof. Superhydrophobic aluminum fins are designed to repel water, potentially preventing problems such as freezing or the accumulation of water droplets in some applications. Superhydrophobic Aluminum Fin Stock has the opposite surface properties of hydrophilic aluminum foil. Its purpose is to prevent condensation water from remaining between the heat exchange fins.

-

Self-Lubricating Aluminum Fin Stock

This type of fin can have a coating or treatment that imparts self-lubricating properties, which can be useful in applications where friction reduction is important.

-

Anti-Mildew Aluminum Fin Stock

Aluminum fins with mildew-resistant properties may be treated or coated to prevent the growth of mold or mildew. Mildew-proof aluminum fins are mainly used in the air conditioning dehumidification part of indoor units. Its main function is to prevent the surface of the heat exchange fins from becoming moldy due to long-term use or storage, thereby improving the ventilation quality of the air conditioner.

Applications of Aluminum Fins

Aluminum fin stock is widely used in the HVAC industry for the production of heat exchanger fins. In addition, it is widely used in the automotive industry for the manufacture of radiators and condensers. Its excellent heat transfer properties, lightweight properties and corrosion resistance make it ideal for these applications.

- 8011 O Aluminium Fin Stock for Air Conditioning

- 3003 Pre-coated Hydrophilicity Aluminum Fin Stock for Heat Exchanger

- 8011 Pre-Coated Gold Color Aluminum Fin Stock for HAVC Heat Exchangers

- 8011 O Blue Pre-coated Hydrophilic Aluminium Fin Stock for Household Air Conditioner

Coated aluminum foil/fin blanks are mainly used in the production of heat exchanger fins such as air-conditioning condensing evaporators, refrigerator frost-free evaporators/finned evaporators, commercial refrigerator condensing evaporators, automobile air-conditioning condensers and evaporators, etc.

Aluminum foil for air conditioning heat exchanger fins

- Thickness: 0.01-0.3mm

- Width: 500-1280mm

- Material (alloy): 1100, 3102, 8011

- Status: O, H22, H24, H26

We can supply 1000 series, 8000 series aluminum foil, etc., or according to customer requirements.

Refrigerator fins anti-frost coated aluminum foil

- Alloy: 1060, 1100, etc.

- Thickness: 0.11mm - 0.18mm

- Width: 150mm - 1240mm

New functional hydrophobic coating is applied to refrigerator heat exchangers to improve frost formation and improve the energy efficiency level of refrigerator products.

Aluminum Fin Stock Manufacturer

Haomei Aluminum is a supplier of high-quality aluminum fin raw materials to the air-conditioning industry, and aluminum roofing and cladding suppliers to the construction industry. All aluminum fins have passed international industry certification standards, and the quality is completely assured. If you don't find the aluminum fin stock you are interested in in our content, you can also contact us and we can provide customized services Email: info@alu-sheet-coil.com.

Typical Aluminum Fin Stock

- 1100 O Aluminum Fin Stock: Soft annealed condition for general formability.

- 1100 H14 Aluminum Fin Stock: Slightly strain-hardened, suitable for moderate strength and formability.

- 1100 H18 Aluminum Fin Stock: Higher strength than H14 due to further strain hardening.

- 1100 H19 Aluminum Fin Stock: Similar to H18 but with higher strength characteristics.

- 1100 H25 Aluminum Fin Stock: Strain-hardened to achieve increased strength.

- 1100 H111 Aluminum Fin Stock: Fully annealed to achieve maximum ductility.

- 1100 H211 Aluminum Fin Stock: Strain-hardened and partially annealed for improved strength and formability.

- 1100 H113 Aluminum Fin Stock: Strain-hardened and partially annealed with a controlled amount of cold work.

- 3003 O Aluminum Fin Stock: Soft annealed condition for good formability and corrosion resistance.

- 3003 H14 Aluminum Fin Stock: Strain-hardened, suitable for moderate strength and formability.

- 3003 H18 Aluminum Fin Stock: Higher strength than H14 due to further strain hardening.

- 3003 H19 Aluminum Fin Stock: Similar to H18 but with higher strength characteristics.

- 3003 H25 Aluminum Fin Stock: Strain-hardened to achieve increased strength.

- 3003 H111 Aluminum Fin Stock: Fully annealed to achieve maximum ductility.

- 3003 H211 Aluminum Fin Stock: Strain-hardened and partially annealed for improved strength and formability.

- 3003 H113 Aluminum Fin Stock: Strain-hardened and partially annealed with a controlled amount of cold work.

These aluminum fin stocks, ranging from annealed (O) to fully hardened (H113) tempers in both 1100 and 3003 alloys, are commonly used in heat exchangers and HVAC components such as air conditioners, radiators, and evaporators.

Aluminum fins, with their efficient heat dissipation capabilities and versatile design, play an indispensable role in maintaining the optimal functioning of various systems. From electronics to automotive and industrial applications, these slender structures demonstrate how a seemingly simple component can have a profound impact on the performance,

efficiency, and longevity of diverse technologies. As the demand for effective thermal management continues to grow, aluminum fins stand as a testament to the marriage of material science and engineering innovation in the pursuit of efficient heat dissipation solutions.