- Cigarette Aluminum Foil Paper Specifications

- Cigarette Aluminum Foil Paper Key Characteristics

- Chemical composition of aluminum foil for cigarette packaging

- Mechanical properties of aluminum foil for cigarette packaging

- The Types of Smoking Aluminum Foil Paper

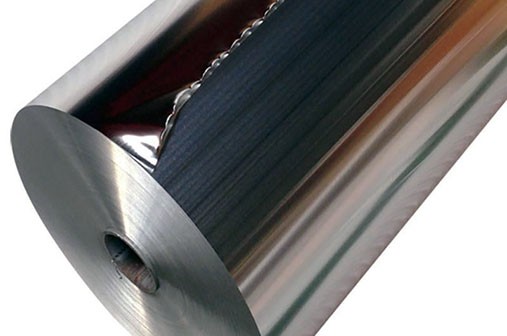

- Cigarette Aluminum Foil Paper Manufacturing Process

- Cigarette Aluminum Foil Quality Requirements for Aluminum Foil

- Conclusion

Cigarette aluminum foil, a specialized material designed for the tobacco industry, plays a crucial role in preserving the quality and freshness of cigarettes. This thin, flexible, and heat-sealing foil is meticulously engineered to meet the unique requirements of the tobacco manufacturing process.

Cigarette aluminum foil is used as the inner lining of cigarette packages. Aluminum foil acts as a barrier to moisture, light and oxygen, maintaining the freshness, flavor and aroma of the tobacco in the cigarette.

Cigarette Aluminum Foil Paper Specifications

Cigarette aluminum foil is typically made from a specific alloy known for its exceptional properties. Commonly, alloy 1235 or 8011 is used due to its high purity, excellent formability, and resistance to corrosion. These alloys ensure that the foil meets the stringent standards set by the tobacco industry for both performance and safety.

| Type | Flexible Packaging Foil |

|---|---|

| Alloy | 1235 8011 8079 |

| Temper | O |

| Thickness | 0.0055MM-0.03MM |

| Width | 200MM-1600MM |

| Color | Golden, Silver (or as request) |

| Surface | One side bright, One side matt |

| Packaging | Free Fumigated wooden box |

Cigarette Aluminum Foil Paper Key Characteristics

Barrier Properties

Cigarette aluminum foil serves as a barrier against external elements such as moisture, light, and oxygen. These properties are essential for preserving the freshness and flavor of tobacco products.

Heat Sealing

The foil's ability to form a tight seal is crucial during the cigarette packaging process. It ensures that each cigarette remains tightly wrapped, preventing the intrusion of external contaminants.

Printability

Cigarette aluminum foil often serves as a printable surface, allowing for the inclusion of branding, health warnings, and other essential information. The printability ensures that the packaging complies with regulatory requirements while providing a platform for brand communication.

Flexibility

The foil's flexibility is essential for the efficient operation of high-speed cigarette packaging machines. It allows for seamless wrapping around each cigarette, contributing to the overall speed and efficiency of the manufacturing process.

Regulatory Compliance

The production and use of cigarette aluminum foil are subject to strict regulations imposed by health authorities and industry standards. These regulations are designed to ensure the safety of the product and compliance with packaging guidelines, including the display of health warnings and other mandatory information.

Chemical composition of aluminum foil for cigarette packaging

| Elements | Composition /% | |||||

| 1235 | 1145 | 8011 | 8111 | 8021 | 8079 | |

| Si | 0-0.65 | Si+Fe 0.55 | 0.50-0.90 | 0.30-1.10 | 0-0.15 | 0.05-0.30 |

| Fe | 0-0.65 | - | 0.60-1 | 0.40-1 | 1.20-1.70 | 0.70-1.30 |

| Cu | 0-0.05 | 0.05 | 0-0.10 | 0-0.10 | 0-0.05 | 0-0.05 |

| Mn | 0-0.05 | 0.05 | 0-0.20 | 0-0.10 | - | - |

| Mg | 0-0.05 | 0.05 | 0-0.05 | 0-0.05 | - | - |

| Cr | - | - | 0.05 | 0-0.05 | - | - |

| Zn | 0-0.1 | 0.05 | 0-0.10 | 0-0.10 | - | 0-0.10 |

| Ti | 0-0.06 | 0.03 | 0-0.08 | 0-0.08 | - | - |

| V | 0-0.05 | 0.05 | - | - | - | - |

| Al | Rem | Rem | Rem | Rem | Rem | Rem |

Mechanical properties of aluminum foil for cigarette packaging

| Alloy | Temper | Thickness /mm | Tensile strength /MPa | elongation after break /%, (not less than) | |

| A50mm | A100mm | ||||

| 1145 1235 | O | 0.0060 - 0.0090 | 45-95 | 0.5 | |

| 8011 8111 8021 8079 | 50-105 | 1.0 | |||

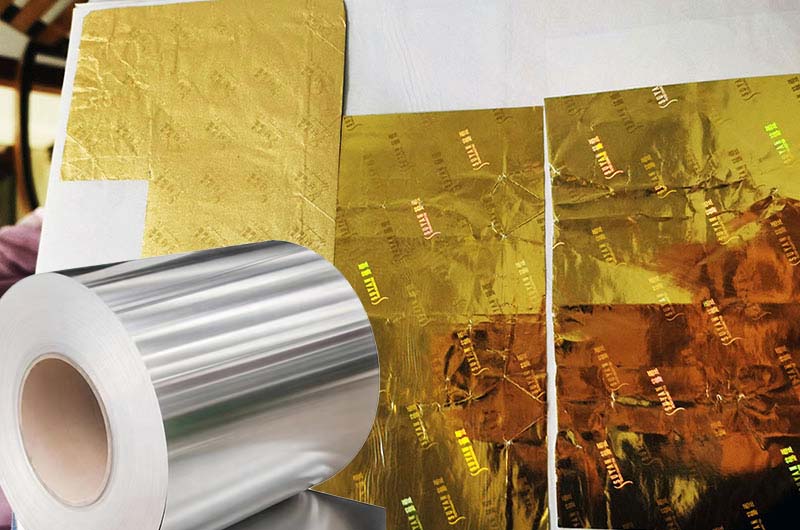

The Types of Smoking Aluminum Foil Paper

Smoking aluminum foil paper comes in various types, each designed to cater to different preferences, aesthetics, and marketing strategies. Here are some common types of smoking aluminum foil paper:

Silver Cigarette Aluminum Foil Paper

- Bright (Shiny): Reflective and glossy surface, giving a classic and polished appearance.

- Dull (or Dumb): Matte or non-reflective finish, providing a more subdued and sophisticated look.

Golden Cigarette Aluminum Foil Paper

- Bright (Shiny): Lustrous and reflective, conveying a sense of luxury and premium quality.

- Dull (or Dumb): Matte finish, offering a more understated elegance.

Printed Cigarette Aluminum Foil Paper

- Customized designs, patterns, brand logos, and information are printed on the foil.

- Allows for unique branding and creative packaging.

Holographic Cigarette Aluminum Foil Paper

- Features holographic effects, creating a dynamic and eye-catching appearance.

- Adds a modern and visually striking element to cigarette packaging.

Embossing Cigarette Aluminum Foil Paper

- Textures or patterns are embossed onto the foil surface, either mechanically or chemically.

- Provides a tactile and visually appealing aspect to the packaging.

Colored Cigarette Aluminum Foil Paper

- Aluminum foil in various colors, offering a wide range of visual options.

- Adds vibrancy and uniqueness to cigarette packaging.

Anti-Counterfeiting Cigarette Aluminum Foil Paper

- Includes security features to prevent counterfeiting and ensure product authenticity.

- Utilizes advanced printing technologies and holographic elements for security.

Cigarette Aluminum Foil Paper Manufacturing Process

1. Rolling and Annealing

The production of cigarette aluminum foil begins with the rolling of aluminum sheets to achieve the desired thickness. Subsequently, the foil undergoes an annealing process, involving controlled heating and cooling, to enhance its flexibility and eliminate any stresses in the material.

2. Surface Treatment

The foil is then treated to ensure a smooth and consistent surface. This step is crucial to maintain the integrity of the heat-sealing process during the cigarette packaging phase.

3. Lubrication

Lubrication is applied to the surface of the foil to facilitate its smooth passage through high-speed cigarette packaging machines. This ensures that the foil can be efficiently wrapped around the cigarette without compromising the production speed.

4. Embossing (Optional)

In some cases, cigarette aluminum foil may undergo embossing, introducing patterns or textures to the surface. This not only serves an aesthetic purpose but can also enhance the foil's strength and flexibility.

Cigarette Aluminum Foil Quality Requirements for Aluminum Foil

The quality requirements for cigarette aluminum foil are stringent, given its critical role in preserving the freshness, integrity, and safety of tobacco products. These requirements ensure that the aluminum foil meets specific standards for manufacturing, printing, and barrier properties. Here are some key quality requirements for cigarette aluminum foil:

1. Alloy and Purity

Aluminum foil for cigarette packaging is typically made from high-purity aluminum alloys such as 1235 or 8011. These alloys are chosen for their excellent formability, strength, and resistance to corrosion.

2. Thickness and Tolerance

The thickness of the aluminum foil is crucial and must adhere to specified standards. Tolerance levels for thickness are typically minimal to ensure consistency in barrier properties and heat-sealing capabilities.

3. Surface Quality

The surface of the aluminum foil should be smooth, free from defects, and without any visible imperfections. A consistent and defect-free surface is essential for achieving high-quality printing and ensuring proper heat sealing.

4. Printing Quality

If the aluminum foil is intended for printing, it must meet specific requirements for printability. The surface should allow for clear and accurate printing of brand logos, health warnings, and other information required by regulatory authorities.

5. Barrier Properties

The aluminum foil must exhibit excellent barrier properties against moisture, light, and oxygen. These properties are critical for preserving the freshness and quality of the tobacco inside the cigarette package.

6. Heat-Sealing Performance

The foil should have optimal heat-sealing properties to ensure a secure and airtight seal during the cigarette packaging process. This prevents the ingress of external contaminants and maintains the integrity of the product.

Conclusion

Cigarette aluminum foil, often overlooked in the consumer's eye, plays a pivotal role in maintaining the quality and integrity of tobacco products. Its unique composition, manufacturing process, and key characteristics contribute to the efficient packaging of cigarettes, ensuring that each product reaches the consumer in optimal condition.

As technology advances, the continuous improvement of cigarette aluminum foil remains a focus, reflecting the industry's commitment to product quality and safety.