- Where to Use Aluminum Foil for Battery Cases

- Why Use Aluminum Foil for Battery Cases?

- Types of Battery Aluminum Foil

- Advantages of Battery Aluminum Foil

- Mechanical Properties of Battery Aluminum Foil

- Electrical Resistance of Battery Aluminum Foil

- Quality Requirements for Battery-Grade Aluminum Foil

- Common Types of Battery Aluminum Foil

- Manufacturing Process of Battery Aluminum Foil

- Frequently Asked Questions about Battery Case Aluminum Foil

Battery technology is evolving rapidly, and the materials used in battery construction play a crucial role in enhancing performance, efficiency, and safety. One such vital component is the battery shell aluminum foil, a thin yet indispensable layer that contributes significantly to the overall functionality of batteries.

Aluminum foil plays a crucial role in battery manufacturing and performance. As an essential component, it contributes to the structural integrity, conductivity, and overall efficiency of various batteries.

The term "battery foil" usually refers to aluminum foil used for electrodes, current collectors, conductors, and substrates in batteries, primarily serving as a conductive material and structural support within the battery.

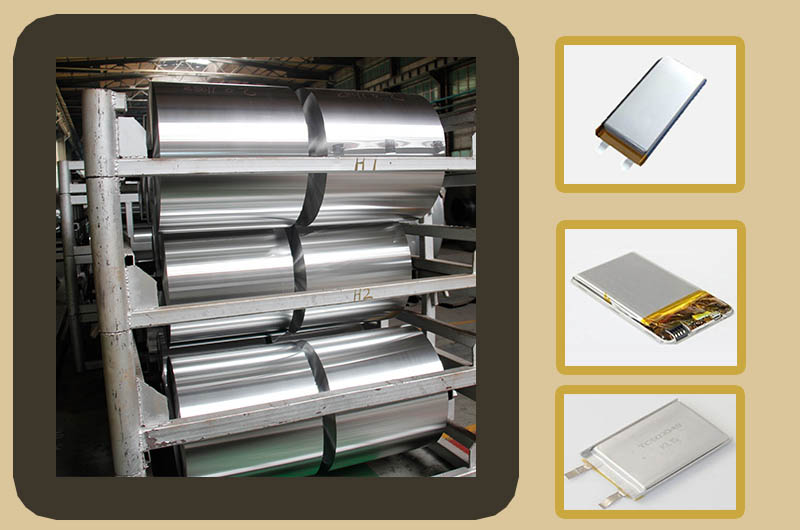

Pouch Battery Foil:

- Structure: This battery casing uses a laminated sheet similar to cold-formed foil products, with a thickness typically of 40-50 µm.

- Application: Pouch batteries use foil laminates similar to pharmaceutical foils to form the casing, offering lightweight and flexible characteristics.

Other Aluminum Battery Components:

Square Battery Casing: These battery casings resemble cans and are usually made from aluminum.

Where to Use Aluminum Foil for Battery Cases

Aluminum foil is widely used in the construction of battery cases for various types of batteries, including lithium-ion batteries, nickel-metal hydride batteries, and others. The foil is commonly employed as a protective layer within the battery casing, acting as a barrier to prevent the penetration of external elements like moisture and oxygen.

Why Use Aluminum Foil for Battery Cases?

Corrosion Resistance: Aluminum foil boasts excellent corrosion resistance properties, making it an ideal choice for battery cases. This characteristic ensures that the foil does not degrade over time, maintaining the structural integrity of the battery.

Conductivity: The high electrical conductivity of aluminum facilitates efficient current flow within the battery, promoting optimal performance.

Lightweight and Ductile: Aluminum is a lightweight and ductile material, allowing for easy forming and shaping to suit various battery designs. This flexibility is crucial for accommodating the diverse shapes and sizes of batteries.

Thermal Management: Aluminum foil aids in thermal management within the battery, dissipating heat generated during operation and preventing overheating, which is vital for safety and longevity.

Types of Battery Aluminum Foil

Lithium battery aluminum foil comes in alloy grades such as 1060, 1050, 1145, and 1235. The 1235 battery aluminum foil is available in states such as -O, H14, -H24, -H22, and -H18.

| Alloy | State | Thickness tolerance(MM) | Width tolerance(MM) | Pipe core specification(MM) | Tensile strength/Mpa | Elongation/% | Dyne value(N/M²) |

| 1235 | H18 | 0. 012-0. 016 | ±3% | Φ76. 2 Φ152. 4 | 170-200 | ≥1. 2 | ≥31*10-3 |

| 0. 0161~0. 020 | ≥1. 4 | ||||||

| 0. 021-0. 035 | ≥1. 6 | ||||||

| 1060 | H18 | 0. 012~0. 016 | 165~190 | ≥1. 2 | |||

| 0. 0161-0. 020 | ≥1. 4 | ||||||

| 0. 021-0. 035 | ≥1. 6 | ||||||

| 1070 | H18 | 0. 012-0. 016 | ≥180 | ≥1. 2 | |||

| 0. 0161-0. 020 | ≥180 | ≥1. 4 | |||||

| 0. 021~0. 035 | ≥170 | ≥1. 6 |

Advantages of Battery Aluminum Foil

1. Excellent Physical Properties

Aluminum foil has outstanding physical properties, including good conductivity and corrosion resistance, which help extend the life of lithium-ion batteries. Its high conductivity ensures efficient current conduction within the battery, while its corrosion resistance protects the battery from environmental factors, enhancing the battery's overall durability and stability.

2. Soft and Easy to Process

The material of aluminum foil is soft and easy to process, making the electrode manufacturing process more efficient. Aluminum foil can be easily cut, stamped, and wound, reducing the demands on equipment and processes during production and thereby lowering the manufacturing costs of electrodes.

3. Protects Current Collectors

Aluminum foil effectively protects the battery's current collectors from mechanical damage and chemical corrosion. This protective function not only enhances battery stability but also further extends the battery's lifespan. By minimizing the loss and deterioration of current collectors, aluminum foil ensures the long-term reliability of the battery.

Mechanical Properties of Battery Aluminum Foil

| Alloy | 1235 | 1145 | 1060 | 1070 |

| Temper | H18 | H18 | H18 | H18 |

| Tensile strength | ≥150N/mm | |||

| Elongation | ≥1% | |||

Electrical Resistance of Battery Aluminum Foil

| Thickness/mm | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.010 | 0.11 | 0.16 |

| Resistance/(Ω.m) | 0.55 | 0.51 | 0.43 | 0.36 | 0.32 | 0.28 | 0.25 |

Quality Requirements for Battery-Grade Aluminum Foil

1. Surface Uniformity, Cleanliness, and Smoothness

The surface of the aluminum foil must be uniform, clean, and smooth. It should be free from noticeable roll marks, dents, pinholes, and corrosion traces. These defects can affect the performance of the aluminum foil and the overall quality of the battery, so it is essential to ensure that the surface is free from any abnormal physical damage or chemical corrosion.

2. No Rolling Defects

The surface of the aluminum foil should be free from creases, stains, bright lines, and other rolling defects. These defects are typically caused by uneven pressure or temperature changes during manufacturing, which can impact battery performance and lifespan. Therefore, the foil must be processed to high-quality standards during rolling to avoid these defects.

3. No Color Variations

The aluminum foil surface should have a consistent color with no color variations. Color differences may be caused by material inconsistencies or inadequate control during production, which can affect battery consistency and performance. Therefore, it is crucial to ensure that the color of the foil remains consistent throughout the production batch.

4. No Oil Contamination or Stains

The aluminum foil surface must be free from oil contamination, strong oil odors, and visible oil stains. Oil contamination and stains can affect the cleanliness of the foil and the contact performance of the battery, so it is necessary to avoid oil contamination during production and handling to maintain the purity and quality stability of the foil.

Common Types of Battery Aluminum Foil

- Plain Aluminum Foil: This is the standard form of aluminum foil used in batteries. It is typically high-purity and free of coatings or treatments. Plain aluminum foil is valued for its good electrical conductivity and mechanical support for electrodes.

- Coated Aluminum Foil: This type of foil features a coating of additional materials. For instance, a carbon coating can enhance conductivity, improve adhesion of active materials, and increase the surface area available for electrochemical reactions. Polymer coatings might be applied to boost chemical stability, prevent oxidation, or provide barrier properties.

- Textured Aluminum Foil: The surface of this foil is intentionally textured to expand the surface area available for electrochemical reactions. It is commonly used in batteries like lithium-ion, where a larger electrode/electrolyte interface is essential. The increased surface area supports faster ion transport, improving the battery’s capacity and power output.

- Ultra-Thin Aluminum Foil: Designed for applications requiring minimal weight and thickness, ultra-thin aluminum foil can be just a few micrometers thick. This type is ideal for producing lightweight and flexible batteries, which are crucial for portable devices and applications with strict space limitations.

- Laminated Aluminum Foil: This foil consists of multiple layers of aluminum foil bonded together with adhesives or other materials. It is used in battery designs that require enhanced mechanical strength and stability. Laminated aluminum foil offers greater protection against punctures, tears, and deformation during assembly and operation.

Manufacturing Process of Battery Aluminum Foil

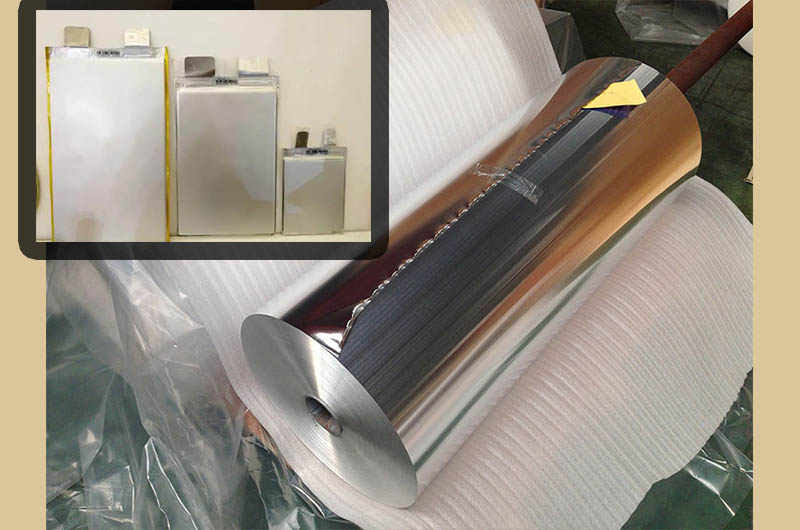

Aluminum foil used in batteries is produced through a multi-step process involving rolling, annealing, and finishing stages. Here is an overview of the manufacturing process for aluminum foil used in batteries:

- Casting: Aluminum is melted and cast into large rectangular or cylindrical blocks, known as billets or logs.

- Hot Rolling: The aluminum blocks are heated and rolled through a series of mills to reduce thickness and increase length. This step is performed at high temperatures to enhance the aluminum's ductility.

- Cold Rolling: The aluminum strip is further rolled at room temperature to reduce thickness and improve surface smoothness. This step ensures the foil achieves the required thickness and tolerance.

- Annealing: The cold-rolled aluminum strip is heated to a specific temperature and then slowly cooled to improve the foil's flexibility and strength.

- Finishing: The aluminum strip is trimmed to the desired width and length, and edges are smoothed to ensure uniformity. Surface treatments, such as texturing, coating, or laminating, may also be applied.

- Quality Control: Strict quality checks are performed throughout the production process, including thickness measurement, surface inspection, and conductivity testing, to ensure the foil meets standards.

- Slitting and Packaging: The finished aluminum foil is slit into rolls of the required width and packaged to protect it during storage and transportation.

Frequently Asked Questions about Battery Case Aluminum Foil

Can I use any aluminum foil for a battery case?

No, it is essential to use aluminum foil with the appropriate alloy and specifications to meet the requirements of the specific battery type.

How does aluminum foil contribute to battery safety?

Aluminum foil enhances safety by providing a corrosion-resistant barrier, aiding in thermal management, and ensuring consistent electrical conductivity.

What should I do if I notice corrosion on the aluminum foil?

If corrosion is observed, it is crucial to investigate the root cause and address it promptly. This may involve using a more corrosion-resistant alloy or implementing protective coatings.

Battery shell aluminum foil is a critical component in the construction of various types of batteries, contributing to their performance, safety, and longevity. The choice of alloy and adherence to specifications are paramount to achieving optimal results.

As battery technology continues to advance, the role of aluminum foil in enhancing battery performance will likely become even more pronounced.