Aluminum foil is often used in air conditioning systems to help improve energy efficiency and protect equipment. The foil acts as a barrier to prevent air leaks and isolate pipes, which helps maintain a constant temperature and reduces energy loss. Additionally, aluminum foil is also commonly used to wrap air conditioning coils to help increase their efficiency and longevity.

Pharmaceutical aluminum foil has excellent barrier properties, which can effectively prevent moisture, light, oxygen and other gases from entering the packaging, and protect drugs from harmful factors such as degradation and oxidation.

Haomei Household Aluminum Foil has uniform thickness, uniform surface coating, is not easy to fall off, has good temperature resistance, high tensile strength, can withstand certain tensile and tearing forces, and is not easy to break during use.

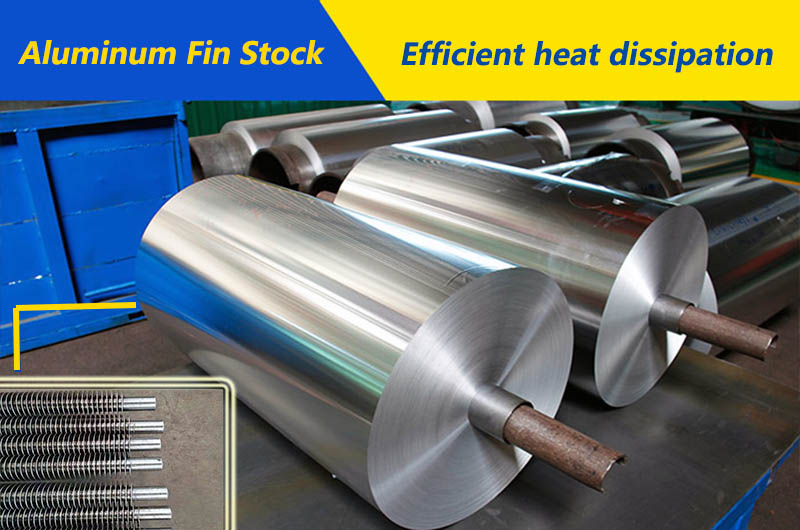

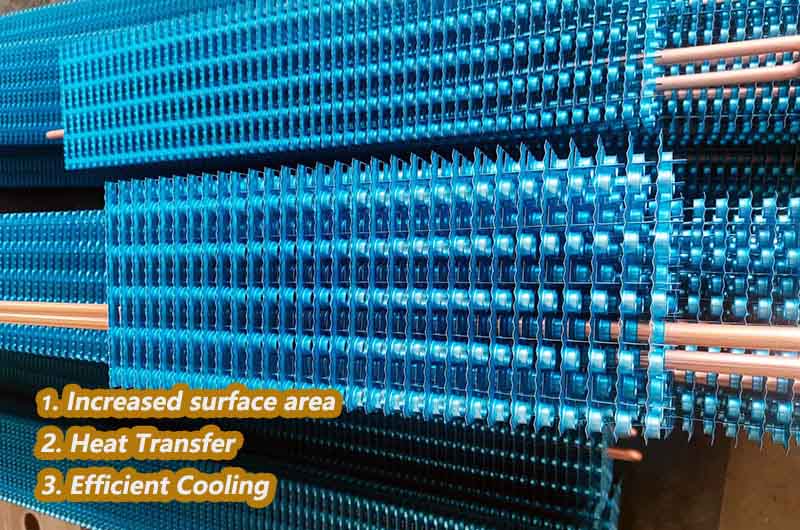

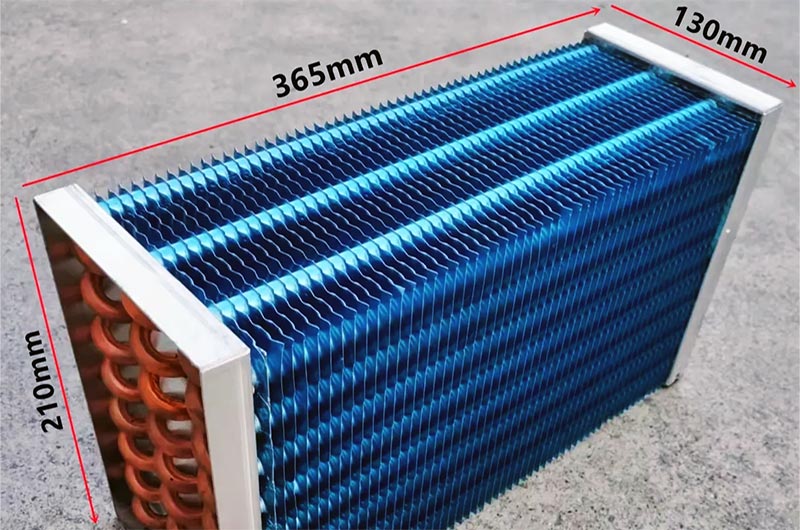

Aluminum fins play an indispensable role in maintaining optimal operation of various systems due to their efficient heat dissipation ability and multifunctional design.

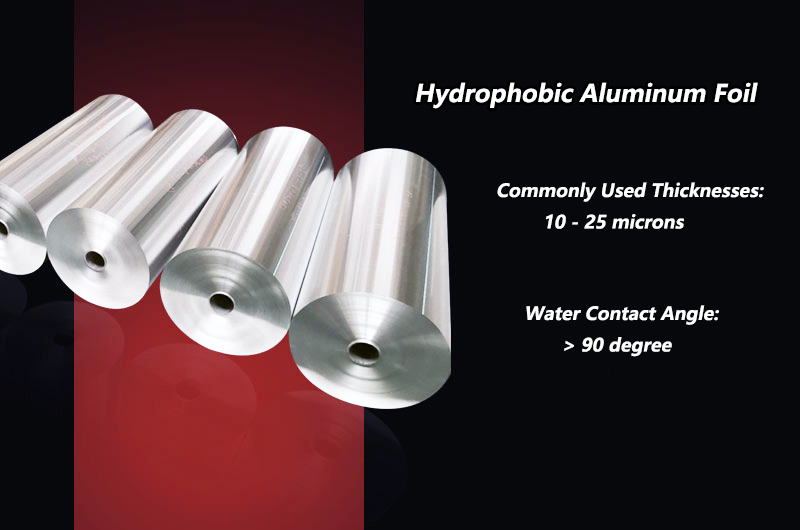

Hydrophobic aluminum foil can prevent water from adhering to the surface, making it effortless to roll up and roll off.

Hydrophilic aluminum foil refers to aluminum foil that has undergone surface treatment to make it hydrophilic. The surface of aluminum foil can attract and retain water molecules.

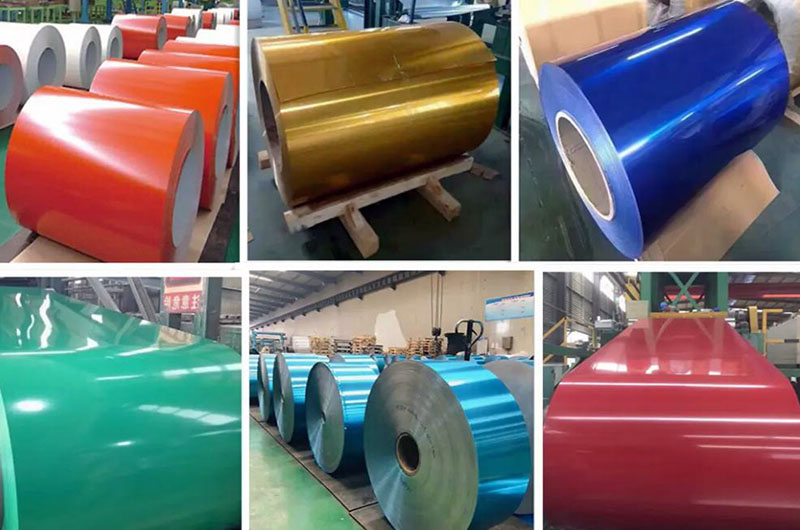

The performance of color coated aluminum foil is very stable, and the coating color can be used for many years without fading. Colored aluminum foil can withstand water, steam, light, taste, corrosion, heat, and low temperatures, and is not easily affected by the environment and temperature.

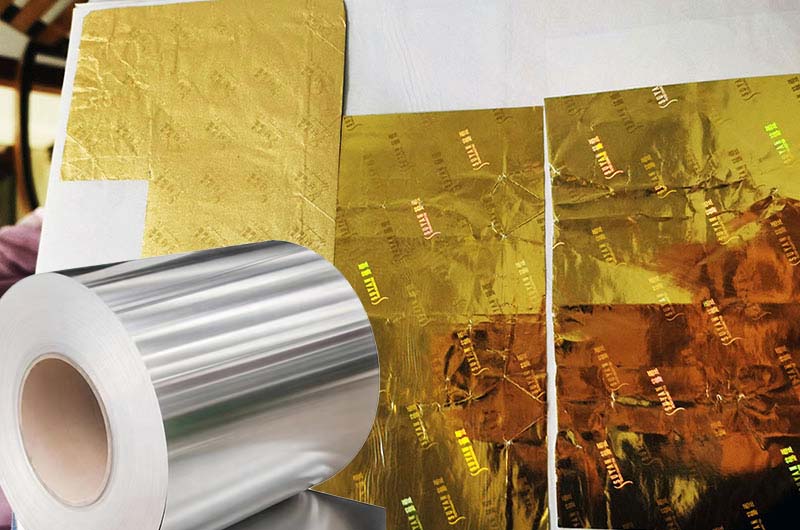

Aluminum foil has become an indispensable material in various industries, thanks to its versatility, flexibility, and excellent barrier properties. Among the specialized variations of aluminum foil, "Hot Seal Aluminum Foil" stands out as a crucial component in packaging applications.

Food grade aluminum foil is a versatile and indispensable tool in the modern kitchen, offering a myriad of benefits for food storage, cooking, and grilling.

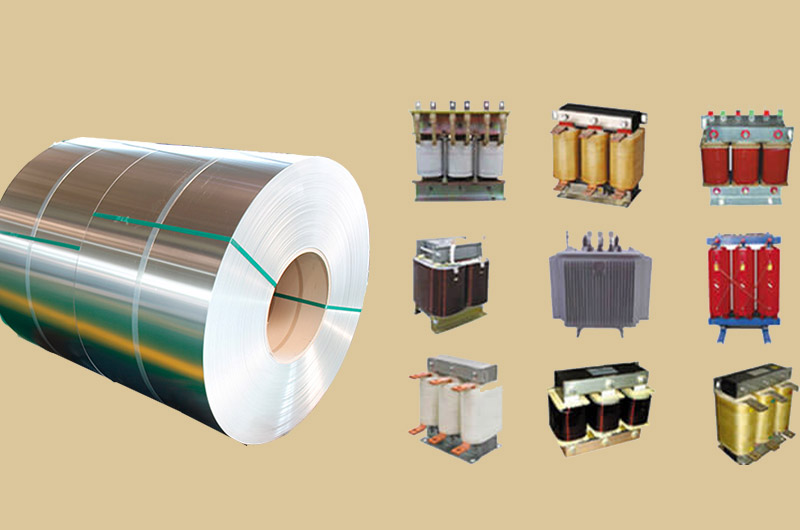

Transformer aluminum foil generally uses 1050 aluminum foil, 1060 aluminum foil, 1070 aluminum foil, and 1350 aluminum foil. They have soft texture, high conductivity, flat surface, smooth edges, and no burrs.

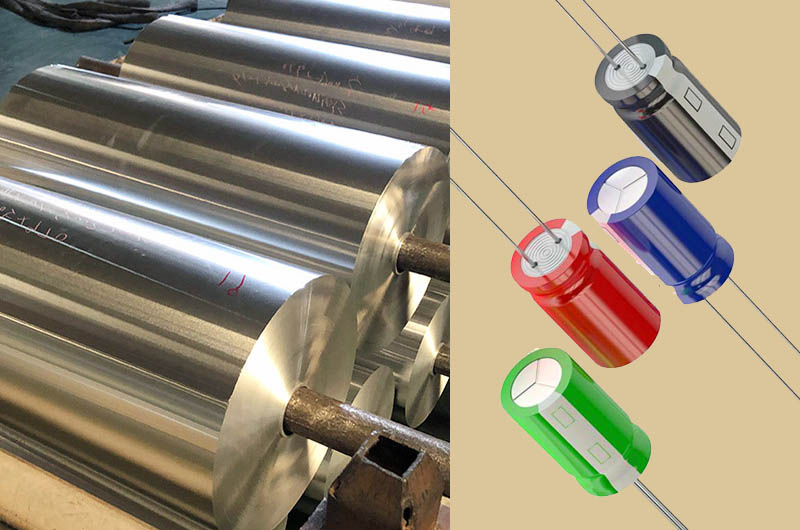

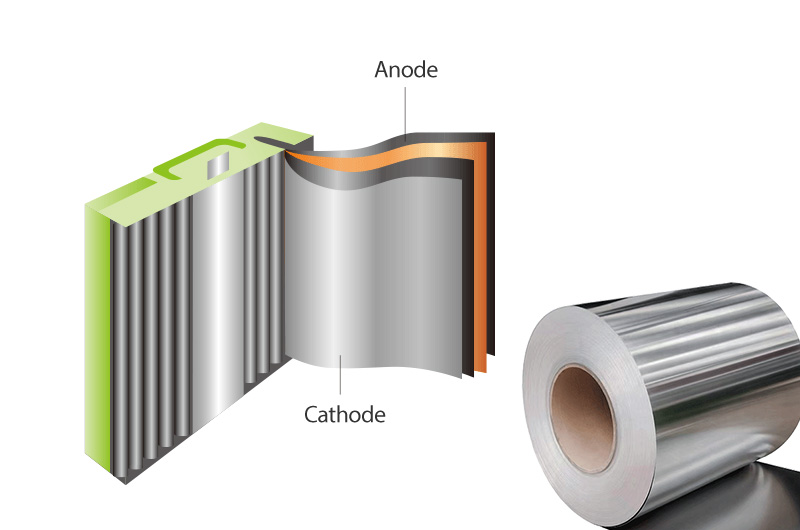

Electrolytic capacitors are essential components in electronic circuits, serving as energy storage devices that store and release electrical energy. The key component that defines the performance of electrolytic capacitors is the aluminum foil used in their construction.

Blister aluminum foil blocks 100% moisture, air, gas, and light, maximizing break-free molding capabilities and ensuring "zero defects."

This specialized foil plays a crucial role in sealing and preserving the contents of containers, particularly in the food and beverage industry.

Electronic aluminum foil is processed from aluminum material into aluminum foil, then undergoes surface corrosion treatment and oxidation treatment, and then is rolled and finally made into a capacitor.

Due to the high sealing and shielding properties of aluminum foil, aluminum plastic foil with plastic film on one or both sides is an ideal cable protection layer.

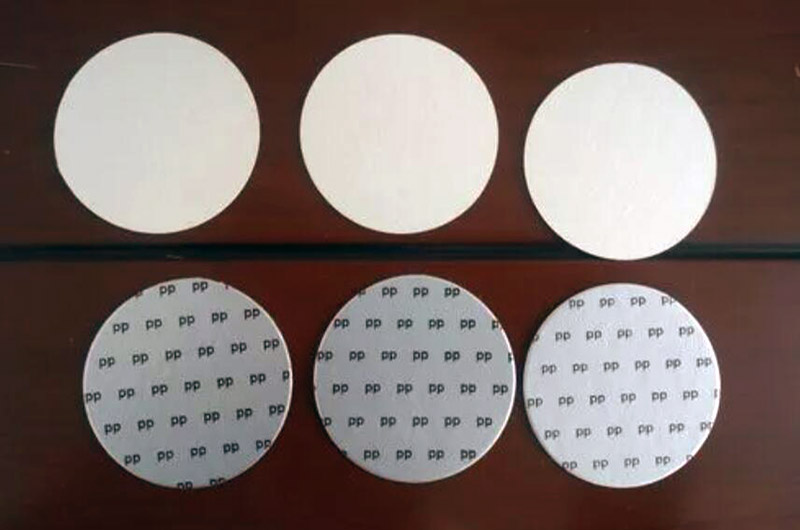

Battery shell aluminum foil is a critical component in the construction of various types of batteries, contributing to their performance, safety, and longevity.

Aluminum foil is not directly used for wine bottle caps, but is often used as a decorative material to cover the top of a wine bottle, providing a finishing touch to the packaging.

Cigarette aluminum foil is used as the inner lining of cigarette packages. Aluminum foil acts as a barrier to moisture, light and oxygen, maintaining the freshness, flavor and aroma of the tobacco in the cigarette.

Aluminum fins stand out among the critical components of heat exchangers used in industries ranging from HVAC systems to automotive applications, especially when coated with advanced materials.

Aluminum fins in heat sinks help increase surface area, improve heat transfer and overall enhance thermal performance, which is critical to the proper operation of machinery and systems.

Aluminum fins play a key role in promoting efficient heat transfer between the refrigerant and the surrounding air. The main purpose is to increase the surface area available for heat exchange and improve system performance.

Flexible packaging refers to materials that are composed of aluminum foil and a variety of different base materials to form a structure to package specific goods. Commodity foils serve the flexible packaging industry by providing the ultimate moisture and vapor barrier in the form of aluminum foil.

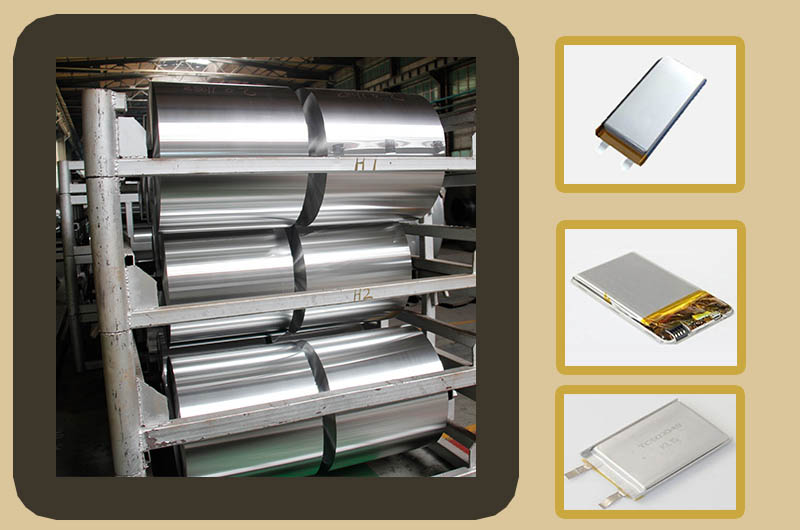

Battery foil is one of the base materials for new energy vehicle lithium batteries. The lithium-ion battery industry often uses rolled aluminum foil as the cathode current collector.

8011 Cooking Aluminum Foil has excellent formability, high moisture barrier, light barrier, gas barrier and good thermal conductivity. These properties make it ideal for cooking and food packaging applications.

The advantages of aluminum foil lunch boxes include light weight, good thermal conductivity, versatility, corrosion resistance, barrier properties, recyclability, cost-effectiveness, durability and easy disposal.