- What is a Lighting Aluminum Disc Circle?

- Why is Aluminum Used for Lighting Disc Circles?

- Do Aluminum Disc Circles for Lighting Fixtures come in Different Finishes?

- Lighting Aluminum Disc Circle Specification

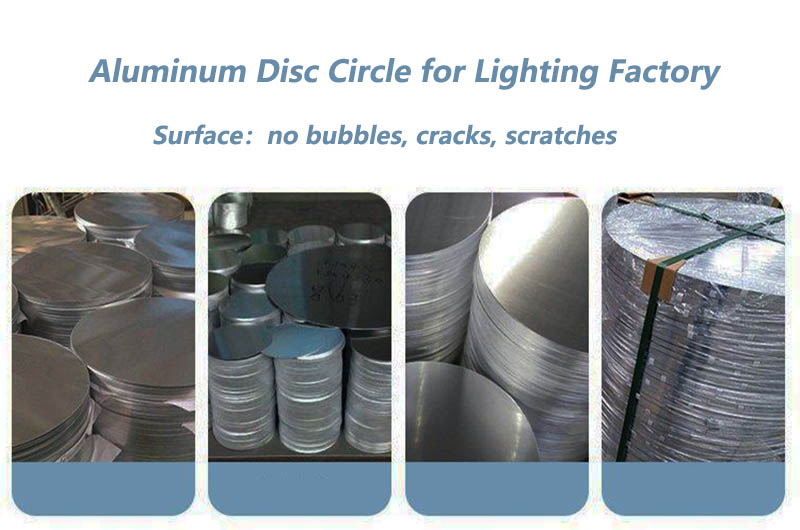

- Aluminum Disc Circle for Lighting Factory

- Lighting Aluminum Disc Circle Performance

- Lighting Aluminum Disc Classification

- Common Lighting Aluminum Disc

- Lighting Aluminum Application

- How to Choose the Alloy used in Lighting Aluminum Disc Circle?

- What are the Production Methods of Lighting Aluminum Disc Circle and which one is better?

- Are Lighting Aluminum Disc Circles Suitable for both Residential and Commercial Lighting Applications?

- Can Lighting Aluminum Disc Circles be Recycled?

What is a Lighting Aluminum Disc Circle?

A lighting aluminum disc circle is a circular piece of aluminum typically used in the construction of lighting fixtures, such as ceiling lights, chandeliers, and pendant lights. It serves as the base or frame for holding light sources, bulbs, or LEDs.

Aluminum discs are usually made of 1050, 1060 or 3003 aluminum alloy, known for their excellent thermal conductivity, electrical conductivity and formability.

Why is Aluminum Used for Lighting Disc Circles?

Aluminum is a popular choice for lighting disc circles because it is lightweight, corrosion-resistant, and has good heat dissipation properties. These qualities make it suitable for supporting and dispersing heat from lighting elements.

Do Aluminum Disc Circles for Lighting Fixtures come in Different Finishes?

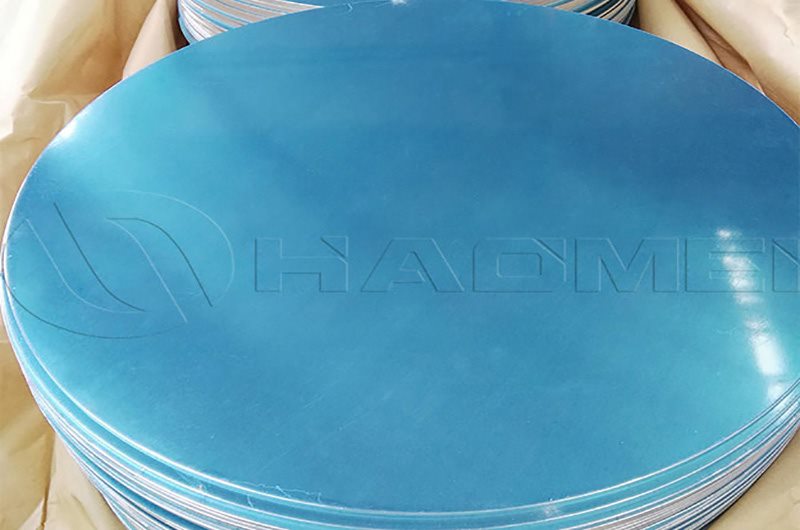

Yes, lighting aluminum disc circles are available in various finishes, including polished, brushed, anodized, or painted. The choice of finish can affect the appearance and aesthetics of the lighting fixture.

Aluminum disc circles for lighting are lightweight, durable and corrosion resistant, can be easily made into desired shapes and sizes, and their high reflectivity makes them ideal for use in reflective lighting assemblies.

Lighting Aluminum Disc Circle Specification

Can Lighting Aluminum Disc Circles be Customized in Terms of Size and Design?

Yes, many manufacturers offer customizable options for lighting aluminum disc circles. You can often choose the size, thickness, and design elements to match your specific lighting fixture requirements.

The specific specifications of aluminum discs for lighting may vary according to the requirements of lighting manufacturers, but generally have the following characteristics :

- Alloy : 1050, 1060 or 3003

- Status : O, H12, H14, H16, H18, H22, H24, H26, H32

- Thickness : 0.5mm - 4mm

- Diameter : 50mm - 1200mm

- Surface treatment : polished, Mirror polished, anodized or coated

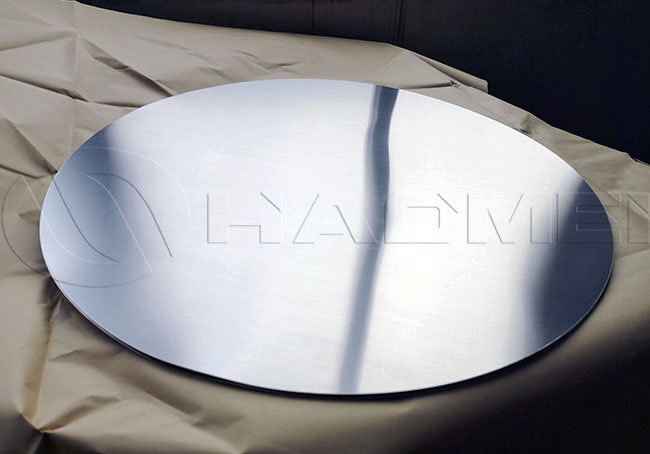

- Appearance : The surface is smooth and clean without scratches, complete, oily, oxidized, and without burrs on the cutting edge

- Application : Lighting lamps, lampshades, reflectors and other lighting components

The production of aluminum discs for lighting typically involves cutting, stamping and forming the aluminum alloy, followed by surface treatment and coating to improve its durability and corrosion resistance.

Aluminum Disc Circle for Lighting Factory

- Appearance : The surface flatness of the aluminum disc meets the customer's standard, and there are no bubbles, cracks, scratches and other defects on the surface.

- Size : Strictly control the diameter, thickness, roundness, etc. of the aluminum disc to ensure that it meets the specified dimensional accuracy requirements.

- Physical properties : test hardness, tensile strength, yield strength, elongation, elongation at break, etc., to ensure that the strength, toughness, plasticity and other properties of aluminum discs meet the standard requirements.

- Chemical composition : Use a chemical analyzer to test the chemical composition of the aluminum disc to ensure that its composition meets the specified standard requirements.

Lighting Aluminum Disc Circle Performance

- High reflectivity : the aluminum disc can reflect more light, improving the brightness and lighting effect of the lamp.

- Corrosion resistance : Lighting Aluminum Disc Circle has good corrosion resistance. When the lamps are usually used for a long time, to ensure that the lamps will not have problems such as corrosion and discoloration after long-term use.

- Strength and Hardness : Lighting Aluminum Disc Circle has sufficient strength and stiffness. Lamps need to have a certain strength and hardness to withstand the load of the lamp and the impact, vibration, etc. during use.

- Surface treatment performance : The surface of Lighting Aluminum Disc Circle can be anodized, sprayed, painted, etc. to meet different design and decoration requirements.

- Dimensional Accuracy : Lighting Aluminum Disc Circle has high precision dimensional control capability. For customers who need to make lamps with high precision requirements, to ensure that the geometric shape and size of the lamps meet the requirements.

Lighting Aluminum Disc Classification

Anodized Aluminum Discs Circle for Lighting

Aluminum Oxide Sanding Discs need to have good processing performance and high reflectivity to meet higher processing requirements.

- Specific application : aluminum oxide disc is mainly used for lighting fittings, reflectors, etc. For example, it can be made into a heat sink for LED lights, or a screen reflector for electronic products, etc.

- Specifications : The diameter is generally within 100mm, and the thickness is usually between 0.3mm-3mm.

- Commonly used alloys : 1050, 1060, 1070, 1100, etc.

- Alloy state : O state

Aluminum Polishing Disc Circle for Lighting

- Specific application : This aluminum disc is mainly used for reflectors, brackets, etc. of lighting fixtures. For example, it can be made into various shapes of reflectors, brackets, lamp holders, etc.

- Specifications : The diameter is generally within 300mm, and the thickness is usually between 0.3mm-3mm

- Commonly used alloys : 1050, 1060, 1070, 1100, etc.

- Alloy state : O/H12/H14 state

In occasions that require higher strength and toughness, semi-hard state (H12/H14 state) can be used;

In the case where a high surface finish is required, a soft (O state) aluminum disc can be used for polishing.

Coated Aluminium Circle Disc for Lighting

- Specific applications : lighting reflectors, brackets, etc., the surface coating can be customized according to customer needs.

- Specifications : The diameter is generally within 300mm, and the thickness is usually between 0.3mm-3mm.

- Commonly used alloys : 3003, 3004 and other aluminum-manganese alloys, 5052, 5083 and other aluminum-magnesium alloys.

- Prepainted color : according to customer needs, the surface is sprayed with different colors of paint to meet different design requirements.

- Alloy state : H14/H16/H18

3003 and 3004 aluminum alloys have good corrosion resistance and weldability, and the price is relatively low. They are commonly used alloys for making lighting fixtures.

5052 and 5083 aluminum alloys have higher strength and corrosion resistance, and are often used in occasions that require higher strength, such as making large lighting fixture brackets.

It should be noted that the above specifications and alloy states are for reference only, and specific requirements may vary with different customers and manufacturers. When selecting suitable aluminum discs and aluminum rings, it should be selected according to specific requirements and application scenarios.

Common Lighting Aluminum Disc

1050 Aluminum Disc Circle for Lighting

1050 Aluminum Disc Circle for Lighting has good deep drawability and formability.

- Common state : O

- Common specifications : 0.5-6mm thick, 100-1000mm in diameter

- Surface treatment : generally calendering or sandblasting

- Advantages : Its advantage is that the cost is low, and it is suitable for the manufacture of simple lamps and kitchen utensils.

- Application : Commonly used in the manufacture of lampshades, decorative parts, kitchen utensils and other products, often used in indoor lighting, such as chandeliers and wall lamps. It is also used in the manufacture of electrical appliances and wires due to its high electrical conductivity.

1060 Aluminum Disc Circle for Lighting

1060 Aluminum Disc Circle has good deep drawability and formability.

- Common state : O

- Common specifications : 0.5-6mm thick, 100-1000mm in diameter;

- Surface treatment : generally calendering or sandblasting

- Advantages : Its advantages are the same as 1050, the cost is lower, and it is suitable for making simple lamps and kitchen utensils.

- Application : Applications similar to 1050 are commonly used in the manufacture of lampshades, decorative parts, kitchen utensils and other products, similar to 1050 aluminum discs, but 1060 aluminum discs are more common in the electrical industry. At the same time, it is also used in the manufacture of kitchen utensils, such as the lining of kitchen utensils.

1100 Aluminum Disc Circle for Lighting

1100 Aluminum Disc Circle has excellent strength, formability and corrosion resistance.

- Common state : O

- Common specifications : 0.5-6mm thick, 100-1000mm in diameter

- Surface treatment : generally calendering or sandblasting

- Advantages : Its advantage is that it is low in cost and has good corrosion resistance and formability.

- Application : It is suitable for the manufacture of high-demand lamps and decorative parts, etc. It is often used in the production of lampshades, decorative parts, kitchen utensils and other products. It is also common in the lighting industry, but it is more suitable for lampshades and lamp accessories. It is also widely used for decoration in restaurants and cafes, such as chandeliers and wall decorations.

3003 Aluminum Disc Circle for Lighting

3003 Aluminum Disc Circle has excellent formability and corrosion resistance.

- Common states : O, H12, H14

- Common specifications : 0.5-6mm thick, 100-1000mm in diameter

- Surface treatment : generally calendering or sandblasting

- Advantages : It has good corrosion resistance and formability.

- Application : It is suitable for the manufacture of lamps and decorative parts with high requirements. It is often used in the manufacture of outdoor lighting and road signal lights. It has excellent corrosion resistance and oxidation resistance.

5052 Aluminum Disc Circle for Lighting

5052 Aluminum Disc Circle has excellent strength, corrosion resistance and weldability.

- Common state : O, H32, H34

- Common specifications : 0.5-6mm thick, 100-1000mm in diameter

- Surface treatment : generally calendering or sandblasting

- Advantages : It has good strength, corrosion resistance and weldability

- Application : It is suitable for the manufacture of lamps and decorative parts with high requirements, and is often used for outdoor lighting, such as street lamps and outdoor lamps. It has high strength and excellent corrosion resistance and is suitable for many environments.

6061 Aluminum Disc Circle for Lighting

6061 Aluminum is an aluminum-magnesium-silicon alloy with excellent strength and machinability.

- Common state : T6

- Common specifications : 6-200mm thick, diameter 100-1500mm

- Surface treatment : generally anodized or sandblasting

- Advantages : It has excellent strength and processing performance

- Application : It is suitable for manufacturing large lamps and high-demand decorative parts, etc., and is usually used in lighting equipment that requires higher intensity, such as overhead lights. At the same time, it is also widely used in aircraft parts and other applications that require high-strength materials.

Lighting Aluminum Application

| Alloy | Application |

|---|---|

| 1100 | Lamps and lampshades for indoor lighting |

| AA3003, AA3004 | Lamps and poles for outdoor lighting |

| AA6061, AA6063, AA6082 | Heat sinks and radiators for LED lighting fixtures |

| AA7075 | Brackets and poles for outdoor lighting |

- Lampshade production : Lighting Aluminum Disc Circle can produce lampshades of various shapes and sizes, including round, square, rectangular, oval, etc., which can be customized according to different lamp shape and size requirements.

- Lamp holder production : Lighting Aluminum Disc Circle can also be used to make lamp holders, such as chandeliers, wall lamps, table lamps, etc. The surface can be treated with various treatments, such as anodizing, spraying, painting, etc., to make it more beautiful.

- Others : In addition to lampshades and lamp holders, Lighting Aluminum Disc Circle can also be used to make various lamp accessories, such as light guide plates, reflector cups, radiators, etc., which can improve the service life and performance of lamps.

Lighting Aluminum Disc Circle has the advantages of light weight, corrosion resistance, and easy processing. It is suitable for various lighting production and application occasions, and is widely used in home lighting, commercial lighting, architectural lighting, automotive lighting and other fields.

How to Choose the Alloy used in Lighting Aluminum Disc Circle?

- Corrosion resistance : For occasions with harsh environments such as indoor or outdoor lighting, it is necessary to choose alloys with good corrosion resistance, such as 3000 series or 5000 series alloys.

- Mechanical properties : For products that need to be processed by deep drawing or drawing, it is necessary to choose alloys with better mechanical properties, such as 1000 series or 5000 series alloys.

- Processing performance : For products that require cutting, stamping, bending and other processing techniques, it is necessary to choose alloys with better processing performance, such as 1000 series or 5000 series alloys.

- Cost : The cost of different alloys is also different, and it needs to be selected according to the actual demand and economy of the product.

When choosing a suitable alloy, it is necessary to comprehensively consider factors such as specific use requirements, processing technology and cost, and make a selection in combination with the technical information and suggestions provided by the supplier.

What are the Production Methods of Lighting Aluminum Disc Circle and which one is better?

There are two main production methods of Lighting Aluminum Disc Circle : rolling and stretching.

- Rolling is to process aluminum alloy blanks through rolling machines to form aluminum discs of required thickness and diameter.

- Stretching is to heat the aluminum alloy billet to a certain temperature, and then stretch it into a disc with the required diameter through a drawing machine.

Production methods have advantages and disadvantages, as follows :

- Rolling method : high production efficiency, low cost, suitable for mass production. However, the rolled aluminum disc has a rough surface, needs to be ground or polished, and has relatively poor strength and toughness.

- Stretching method : The aluminum disc produced has a smooth surface, good strength and toughness, and can meet high-demand application scenarios. However, the production efficiency of the stretching method is low, and the cost is relatively high.

Which production method to choose depends on the specific needs of customers. Different production methods have different prices, please consult us for specific quotations.

Are Lighting Aluminum Disc Circles Suitable for both Residential and Commercial Lighting Applications?

Yes, lighting aluminum disc circles are versatile and can be used in a wide range of lighting applications, including both residential and commercial settings. Their durability and heat dissipation properties make them suitable for various environments.

Can Lighting Aluminum Disc Circles be Recycled?

Yes, aluminum is a highly recyclable material, and lighting aluminum disc circles can be recycled after their useful life. Recycling aluminum is an environmentally friendly option that conserves resources and reduces waste.