- What are Cookware Aluminum Disc Circle?

- Why are Cookware Discs Made of Aluminum?

- How are Aluminum Discs Made?

- What are the Main Advantages of Aluminum Disc Circle for Cookware?

- Aluminium Circle for Cookware Specifications

- Aluminum Disc Circle for Cookware Manufacturer

- Commonly used Kitchen Utensils Aluminum Disc

- Aluminum Disc Circle for Cookware Applications

- Are Aluminum Cookware Safe?

- What are the Cons of Aluminum Cookware?

- Will the Aluminum Disc Warp or Deform Over Time?

- How to Clean and Maintain Aluminum Disc Circle Cookware?

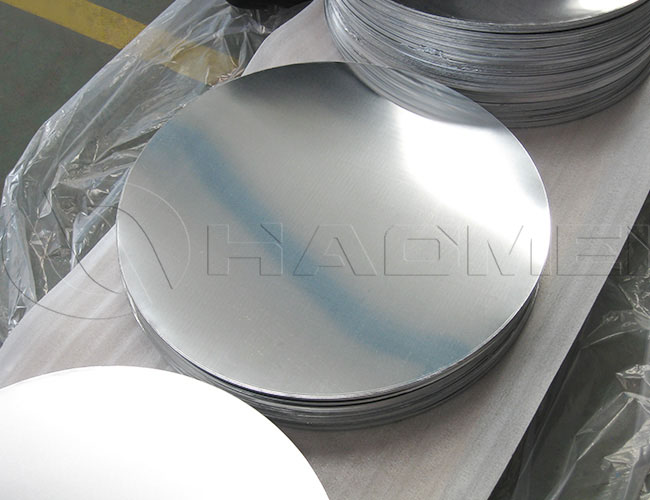

What are Cookware Aluminum Disc Circle?

An aluminum cookware disc is a round piece of aluminum that is used as the base or bottom of various cookware such as pots, pans and cookware sets. It serves as the base of the cookware, providing even heat distribution and retention.

According to incomplete statistics, about half of the cookware in the world is made of aluminum. The thermal efficiency of cooking is as high as 93%, while stainless steel and cast iron are only 1/3 of aluminum.

Why are Cookware Discs Made of Aluminum?

Using aluminum circles to make cookware will greatly increase the physical and chemical properties of the cookware, and improve the electrical conductivity, thermal conductivity, heat resistance and other properties of the cookware.

Aluminum is a popular choice for cookware discs because of its excellent thermal conductivity, which ensures that heat is evenly distributed across the cooking surface. It's also lightweight, durable, and corrosion-resistant, making it an ideal material for cookware bases.

How are Aluminum Discs Made?

Aluminum discs are usually made through a process called deep drawing. Flat aluminum is cut into circles and pressed into the desired shape using a hydraulic press or other similar machinery. The result is a round aluminum pan with the desired thickness and dimensions.

Reminder: It is better to stamp the aluminum disc first, then anneal, and there will be no burrs on the edge.

Cookware rings are usually made of high-quality aluminum alloys and are specially designed for the production of cookware. Commonly used cookware aluminum disc alloys include 1050, 1060, 1070, and 3003, etc. These alloys are lightweight, durable, and corrosion-resistant, making them ideal for use in the kitchen.

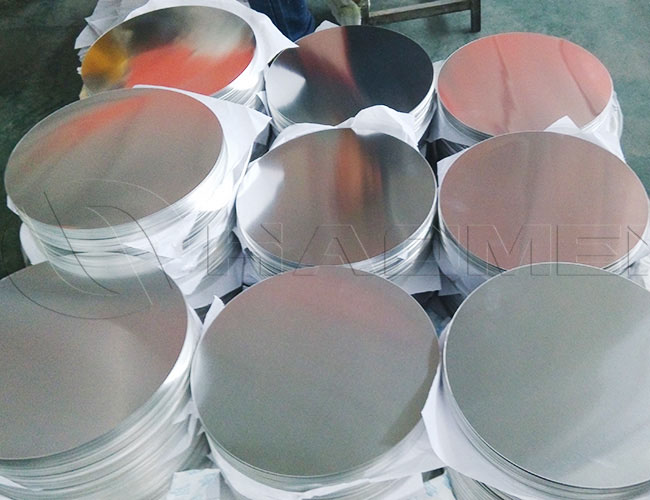

Aluminum circles for cookware come in a variety of sizes and thicknesses, depending on the type of cookware produced. They can be made in various shapes including round, square and rectangular depending on the needs of the manufacturer.

What are the Main Advantages of Aluminum Disc Circle for Cookware?

- Good thermal conductivity : Aluminum is a good thermal conductive metal with fast and uniform thermal conductivity, which can make food heat up quickly and shorten cooking time.

- Lightweight : Aluminum is a lightweight metal, which is lighter than other metals such as iron and steel, making aluminum kitchen utensils easier to operate and less prone to fatigue.

- Corrosion resistance : Aluminum has good corrosion resistance, will not be corroded due to long-term contact with acidic or alkaline substances, and has a longer service life.

- Easy to clean : The aluminum surface is smooth, not easy to adhere to grease and food residue, and it is easier to clean.

- Low cost : Compared with other metal materials such as stainless steel, copper, etc., the price of aluminum is lower, making aluminum kitchen utensils more economical.

Aluminium Circle for Cookware Specifications

- Alloys : The most common alloys used for cookware rings are 1050, 1060, 1070, 1100, 3003, and 5052.

- Condition : The condition of the rims can vary from soft (O) to hard (H32). The most common states used for cookers are O and H14.

- Diameter : The diameter of the aluminum ring can vary from 100mm to 1200mm. The most common sizes for cookware are between 200mm and 600mm.

- Thickness : The thickness of the aluminum ring can vary from 0.5mm to 5mm. The most common thickness for cookware is between 0.7mm and 3mm.

- Surface treatment : The surface treatment of the aluminum ring can be ground, anodized or coated with non-stick material.

- Standard: ASTM-B209, GB/T3880-2012, EN485

- Quality : The circle has no defects such as oil spots, scratches or dents.

Aluminum Disc Circle for Cookware Manufacturer

- Material selection : Select qualified aluminum alloy materials and ensure that the materials meet the requirements of relevant standards.

- Thickness Control : Thickness of aluminum cookware discs is strictly controlled as thickness affects durability and heat uniformity.

- Surface treatment : The surface treatment of the aluminum disc is smooth without sharp edges.

- Coating treatment : The surface is coated to prevent the aluminum disc from contacting with food. Coatings should comply with relevant food safety standards.

- Strength test : Conduct strength test on the aluminum disc to ensure that its bearing capacity and durability meet the standard requirements.

- Testing standard : Kitchen aluminum meets relevant national standards, such as GB4806.1-2016 "General Safety Requirements for Food Contact Materials and Products" and other standards.

- Production link control : In the production link, strictly control raw materials, production technology, equipment management, etc. to ensure stable product quality and meet standard requirements.

Commonly used Kitchen Utensils Aluminum Disc

- 1-4mm 1100/1050 H24 cookware aluminum circle disc for cake mold

- 1-4mm 3003 H24 cookware aluminum circle disc for steamer, stew pot

- 2mm-3mm 1060 O, H12 cookware aluminum circle disc for frying pan

- 3-8mm 6061 T6 cookware aluminum circle disc for baking pan

1100/1050 Aluminum Disc Circle for Cookware

1100/1050 aluminum has good thermal conductivity and workability, and is suitable for making cookware that requires good thermal conductivity.

- Alloy : 1100/1050

- Status : H24

- Common specifications : 1-4mm thickness

- Surface treatment : The corresponding application surface usually needs to be sandblasted to improve its surface roughness and adhesion.

- Application : such as cake mold, etc.

3003 Aluminum Disc Circle for Cookware

3003 Aluminum Disc Circle has good corrosion resistance and machinability, and is suitable for making cookware that requires good corrosion resistance.

- Status : H24

- Common specifications : 1-4mm

- Surface treatment : The corresponding application surface usually needs to be sandblasted or brushed to improve its surface roughness and adhesion.

- Application : such as steamer, stew pot, etc.

6061 Aluminum Disc Circle for Cookware

6061 Aluminum has excellent strength and wear resistance, and is suitable for making cookware that requires higher strength.

- Status : T6

- Common specifications : 3-8mm thickness

- Surface treatment : The corresponding application surface usually needs to be anodized to improve its corrosion resistance and hardness.

- Application : Such as wok, bakeware, etc.

Aluminum Disc Circle for Cookware Applications

Cookware applications: pots, pans, pizza pans, pie plates, cake pans, lids, kettles, basins, frying pans, bowls, cups, utensil applications.

- 3003 O cookware aluminum circle disc for rice cooker

- 3003-O/5052-O cookware aluminum circle disc for pan

- 6061/3003 cookware aluminum circle disc for pressure cooker

- 6061-T6 cookware aluminum circle disc for baking pan

- 1050-O/3003-O cookware aluminum circle disc for steamer

- 1100 O cookware aluminum circle disc for soup pot

- 3003-H12/3003-H14/5052-H32/5052-H34 cookware aluminum circle disc for air fryer

Aluminum Circle for Rice Cooker

An electric rice cooker is a common kitchen appliance, usually consisting of a pot body, an inner tank, a heater and other components. Among them, the aluminum disc is mainly used for the pot body and inner tank of the rice cooker.

- Alloy : 3003

- Status : O

- Surface treatment : Stretching, calendering and other treatments are required to achieve a smooth and smooth effect.

- Common specifications : thickness 0.3-1.0mm, diameter 100-600mm.

- Advantages : The alloy is characterized by good thermal conductivity and corrosion resistance, thus ensuring uniform cooking temperatures and a long service life.

Aluminum Circle for Pan

- Alloy : 3003/5052

- Status : 3003-O or 5052-O

- Surface treatment : the surface needs anti-corrosion treatment

- Common specifications : 0.5mm~4.0mm

- Advantages : These alloys have good thermal conductivity and corrosion resistance, and can also withstand certain mechanical shocks, suitable for making pans.

Aluminum Circle for Body of Pressure Cooker

- Aluminum alloy : 6061/3003

- Status : 6061-T4 or 6061-T6, 3003-H24 or 3003-H26.

- Surface treatment : the surface needs anti-corrosion treatment,

- Commonly used specifications : ranging from 1.0mm to 6.0mm.

- Advantages : These alloys have excellent mechanical properties, can withstand high-pressure and high-temperature shocks, and are not easily deformed or discolored.

Aluminum Disc Circle for Deep Fryers

A fryer is also a common kitchen utensil, usually consisting of a pot body, a handle, a frying basket and other components. Among them, aluminum discs are mainly used for the pot body and frying basket of the fryer.

- Aluminum alloy : 3003 and 5052,

- Status : 3003-H12 or 3003-H14, 5052-H32 or 5052-H34.

- Commonly used specifications : ranging from 1.0mm to 5.0mm.

- Surface treatment : the surface needs to be treated with anti-corrosion treatment and non-stick coating,

- Advantages : These alloys have good thermal conductivity and corrosion resistance, can work stably at high temperatures, and are suitable for making fryers.

Aluminum Disc Circle for Bakeware and Ovenware

- Aluminum alloy : 6061 and 5052,

- Status : 6061-T6 or 5052-H32.

- Surface treatment : The surface needs to be treated with anti-corrosion treatment and non-stick coating.

- Commonly used specifications : ranging from 1.0mm to 5.0mm.

- Advantages : These alloys have good thermal conductivity and mechanical properties, can withstand high temperature and high pressure, and are suitable for making bakeware, oven tableware, etc.

Aluminum Disc Circle for Steamers

- Aluminum alloy : 1050 and 3003

- Status : 1050-O or 3003-O

- Surface treatment : the surface needs anti-corrosion treatment

- Commonly used specifications : ranging from 1.0mm to 5.0mm.

- Advantages : These alloys have good thermal conductivity and corrosion resistance, can work stably at high temperatures, and are suitable for making steamers.

Aluminum Circle for Hard-Anodized Nonstick Cookware

Hard-anodized non-stick pans are usually made of aluminum alloy 3003 or 6061, which are hard-anodized to make them durable and non-stick.

- Alloy : 3003/5052

- Status : H12, H14, H16, H18, H22, H24, H26, H32

- Surface treatment : The surface needs to be anodized to improve the hardness, wear resistance and corrosion resistance of the aluminum disc.

- Commonly used specifications : The commonly used specifications of aluminum discs are 0.5-5.0mm in thickness and 100-1200mm in diameter.

- Advantages : Hard anodizing, a hard oxide layer is formed on the surface, which improves the wear resistance and corrosion resistance of aluminum.

Coated cookware aluminum circle

The color layer of coated cookware aluminum discs will not peel off after drawing or spinning. The main specifications are 2mm-4mm 1100 3003 aluminum rims.

Cladding aluminum circle disc for cookware

For some high-end stainless steel pots, the bottom of the pot has at least 3 layers, two layers are steel, and aluminum sits in the middle. As a heat transfer material, we all know that aluminum has good thermal conductivity, but aluminum is not magnetic, but steel is, so , these cookware can be used in induction cookers.

Are Aluminum Cookware Safe?

Aluminum is a reactive metal that can react with acidic or alkaline foods, causing the metal to leach into the food. This can change the taste of food and pose health risks if eaten in large quantities. However, the amount of aluminum that leaches into food is usually very small and is considered safe by most health organizations.

To minimize the risk of aluminum leaching into food, you can :

- Avoid cooking acidic foods like tomatoes and citrus fruits in aluminum cookware.

- Use anodized aluminum cookware, which has a protective layer that prevents the metal from leaching into the food.

- Avoid scratched or damaged aluminum cookware, as this increases the risk of the aluminum leaching into the food.

What are the Cons of Aluminum Cookware?

- Reactivity with Acidic Foods : Although aluminum does not react with most foods, it can react with acidic foods such as tomatoes and citrus fruits, causing the metal to leach into the food. This can change the taste of food and pose health risks if eaten in large quantities.

- Not Very Durable : Aluminum cookware is relatively soft and prone to dents, scratches and warping over time, especially with heavy use.

- Not Induction Compatible : Aluminum cookware is not magnetic, which means it cannot be used on induction cooktops without an additional induction pan.

- Requires Special Care : To prevent discoloration and corrosion, aluminum cookware requires special care and maintenance. It should not be washed in the dishwasher or soaked in water for a long time.

Will the Aluminum Disc Warp or Deform Over Time?

Aluminum cookware, including pans, may warp or warp if exposed to extreme temperature changes or exposure to high temperatures for extended periods of time. To prevent this, avoid rapid temperature changes and use cookware within the recommended temperature range.

How to Clean and Maintain Aluminum Disc Circle Cookware?

Aluminum Disc Circle Cookware is relatively simple to clean and maintain. Most can be cleaned with warm soapy water and a soft sponge or cloth. Avoid abrasive pads or harsh chemicals that could damage the nonstick or anodized coating.