- Why Choose Aluminum Trailer Roof Coil?

- Typical Aluminum Alloy for Trailer Roof Coil

- Differences Between Alloys

- Advantages of Aluminum Trailer Roof Coils

- How to Choose Aluminum Trailer Roof Coil

- Aluminum Trailer Roof Coil Related Search

- Installation and Maintenance Guidelines

- Conclusion

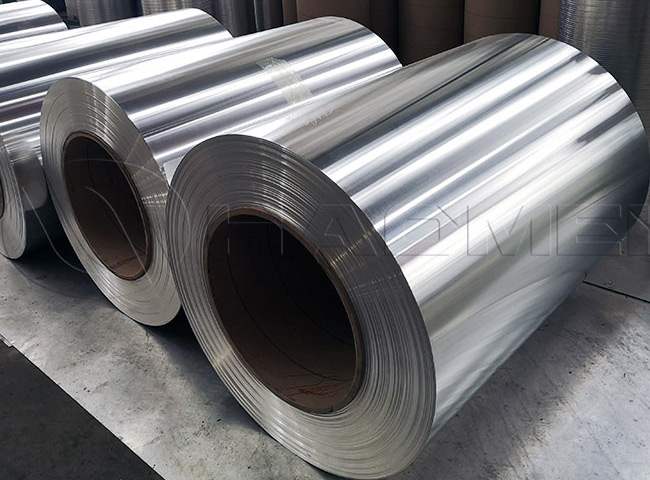

Aluminum trailer roof coil typically refers to a roll or coil of aluminum material that is used for constructing or repairing the roofs of trailers.

Trailers, such as those used for hauling goods, camping, or mobile homes, often have roofs made of aluminum due to its lightweight nature, durability, and resistance to corrosion.

The coil form allows for easy transport, handling, and installation of the aluminum roofing material. These coils are usually available in various thicknesses and widths to accommodate different trailer sizes and designs.

Why Choose Aluminum Trailer Roof Coil?

Aluminum is a popular choice for trailer roofs because it is:

1. Lightweight

Aluminum is much lighter than many other roofing materials, which is crucial for trailers where weight is a significant consideration.

2. Corrosion-resistant

Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This is especially important for trailers that may be exposed to various weather conditions during travel.

3. Durable

Aluminum is a durable material that can withstand the rigors of transportation, including vibrations and potential impacts.

Typical Aluminum Alloy for Trailer Roof Coil

Aluminum trailer roof coils are typically made from specific aluminum alloys to optimize their properties for use in trailer roofing applications. The choice of alloy can impact factors such as strength, corrosion resistance, formability, and cost. Here are some commonly used aluminum alloys in trailer roof coils, along with their differences and considerations for choosing the right one:

3003 Aluminum Trailer Roof Coil

Properties:

- Good formability

- Moderate strength

- Excellent corrosion resistance

Applications:

- Used in general construction and industrial applications

- Suitable for trailer roofs due to its corrosion resistance and formability

5052 Aluminum Trailer Roof Coil

Properties:

- High strength

- Excellent corrosion resistance

- Good formability

Applications:

- Commonly used in marine applications due to its resistance to saltwater corrosion

- Suitable for trailer roofs where higher strength is desired

6061 Aluminum Trailer Roof Coil

Properties:

- Excellent strength

- Good corrosion resistance

- Moderate formability

Applications:

- Often used in structural components where high strength is crucial

- Suitable for trailer roofs where a balance of strength and corrosion resistance is needed

5083 Aluminum Trailer Roof Coil

Properties:

- High strength

- Excellent corrosion resistance

- Good weldability

Applications:

- Commonly used in marine and aerospace applications

- Suitable for trailer roofs where high strength and corrosion resistance are important

Differences Between Alloys

1. Strength

Alloy 6061 and 5083 generally have higher strength compared to 3003 and 5052. Consider the load-bearing requirements of the trailer when choosing an alloy.

2. Corrosion Resistance

All the mentioned alloys have good corrosion resistance, but 5052 and 5083, being marine-grade alloys, offer enhanced resistance to saltwater corrosion.

3. Formability

Alloy 3003 is known for its excellent formability, making it suitable for applications where shaping is crucial. 5052 and 6061 offer a balance of formability and strength.

4. Weldability

Alloy 5083 is known for its good weldability. If welding is a significant part of the trailer roof construction or repair, this may be a crucial factor.

Advantages of Aluminum Trailer Roof Coils

A. Energy Efficiency

The lightweight nature of aluminum contributes to increased energy efficiency in trailers. Reduced weight translates to lower fuel consumption, making aluminum a sustainable choice for environmentally conscious consumers and businesses.

B. Low Maintenance Requirements

Aluminum trailer roofs are known for their low maintenance needs. The material's resistance to corrosion means less worry about rust, and its durability reduces the frequency of repairs. This can result in cost savings and increased overall efficiency.

C. Longevity and Lifecycle Cost

The longevity of aluminum as a roofing material directly impacts the lifecycle cost of trailers. While the initial investment may be higher than some alternatives, the extended lifespan and minimal maintenance requirements make aluminum a cost-effective choice over the long term.

How to Choose Aluminum Trailer Roof Coil

1. Consider Trailer Use

Determine the specific requirements of the trailer's use. For heavy-duty applications, a higher-strength alloy like 6061 or 5083 may be suitable. For general-purpose trailers, 3003 or 5052 may be sufficient.

2. Weight Considerations

If weight is a critical factor, especially for applications like fuel efficiency in commercial hauling, opt for alloys with lower density, such as 3003.

3. Corrosion Resistance

If the trailer is frequently exposed to harsh environmental conditions, such as saltwater or corrosive chemicals, prioritize alloys with enhanced corrosion resistance, such as 5052 or 5083.

4. Formability and Fabrication

Consider the fabrication processes involved. If the material needs to be easily formed or shaped, 3003 is an excellent choice due to its superior formability.

5. Cost Considerations

Evaluate the cost of the alloys, keeping in mind that higher-strength and corrosion-resistant alloys may come at a higher price. Balance the performance requirements with budget considerations.

Aluminum Trailer Roof Coil Related Search

- aluminum roof coil

- aluminum roof coil near me

- aluminum trailer roof repair

- aluminum camper roof replacement

- aluminum roll roofing

- 102'' wide aluminum roof coil

- one piece aluminum trailer roof

- trailer roof sheeting

- horse trailer roof panels

Installation and Maintenance Guidelines

A. Industry Standards

Proper installation is crucial for the performance of an aluminum trailer roof. Following industry standards and guidelines ensures that the roof provides the necessary protection against the elements and maintains its structural integrity throughout its lifespan.

B. Routine Inspections

While aluminum trailer roofs are low maintenance, routine inspections are still recommended. Checking for any signs of damage, loose fasteners, or areas that may require resealing can help address issues before they escalate, extending the roof's lifespan.

C. Repair and Replacement Considerations

In the event of damage, understanding the repair and replacement options for aluminum trailer roofs is essential. Whether addressing a small puncture or considering a full roof replacement, prompt and appropriate action ensures the continued functionality of the trailer.

Conclusion

In the dynamic world of trailers, where reliability, efficiency, and durability are paramount, aluminum trailer roof coils emerge as a versatile and practical solution.

Their lightweight construction, corrosion resistance, and long-term cost-effectiveness make them a popular choice across various industries.

As technology and materials continue to evolve, aluminum remains a stalwart option for those seeking a reliable and resilient roofing solution for their trailers.