- Embossed Aluminum Coil Specifications

- Embossed Aluminum Coil Tolerance

- Embossed Aluminum Coil Types

- Embossed aluminum coil surface treatment

- Embossed Aluminum Coil Manufacturer Quality

- Embossed Aluminum Coil Applications

- Embossed Aluminum Coil Chemical Composition

- Embossed aluminum coil process

Embossed aluminum coils are aluminum products that are rolled on the surface to form various patterns and decorative patterns. Embossed aluminum coils are widely used in packaging, construction, curtain walls, freezers, interior decoration, ceilings, etc.

Aluminum Stucco Embossed Sheet Rolls are typically made of 1060, 1100 and 3003 aluminum sheets that are Stucco embossed, which will make them more durable for both sheets and rolls.

Embossed Aluminum Coil Specifications

According to the thickness classification of embossed aluminum coils, it can be divided into thin, medium, thick, extra-thick, etc. The space and range of embossed aluminum coils with different standards for use are different.

The specifications of embossed aluminum coils may vary according to specific application requirements. However, some common specifications for embossed aluminum coils include :

| Alloy | Temper |

|---|---|

| 1xxx: 1050, 1050A, 1060, 1100, 3003, 5052 | O, H12, H14, H22, H24, H32 |

| 3xxx: 3003 |

| Thickness (Base material) | 0.25~2.0 |

|---|---|

| Width | ≤1500 |

| Length | As per customer’s requirements |

| Embossing depth | 0.08~0.25 |

| Surface Treatment | Mill Finish, bright finish, anodized, color coated |

| Standard Specification | Base material conforms to GB/T 3880, ASTM B209, or EN 485. |

Embossed Aluminum Coil Tolerance

| Thickness (Base material) | 0.25-0.50 | >0.50-2.0 |

|---|---|---|

| Thickness | 0-0.05 | 0-0.10 |

| Embossing depth | +/-0.01 | +/-0.02 |

| Width | +/-0.5 | +/-1.0 |

| Length | +/-1.0 | +/-1.5 |

| Diagonal | +/-1.5 | +/-2 |

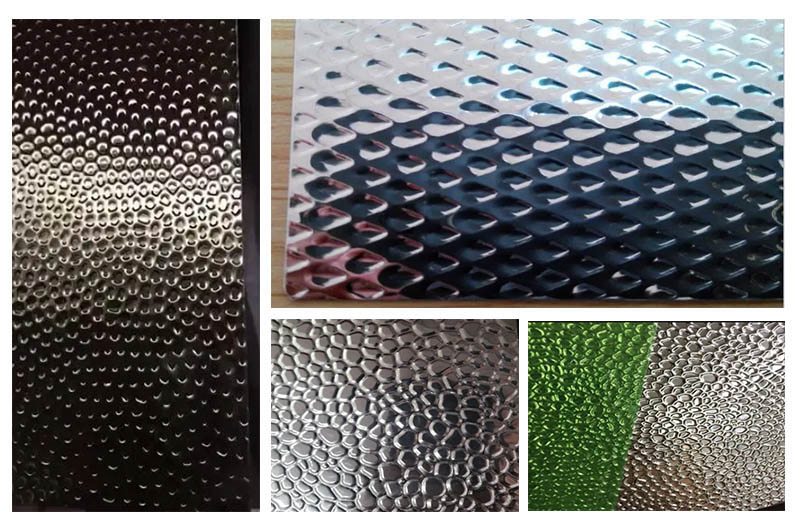

Embossed Aluminum Coil Types

- Stucco Embossed Aluminum Coil

- Orange Peel Embossed Aluminum Coil

- Diamond Embossed Aluminum Coil

- Rhombus Embossed Al uminum Coil

- Hemisphere Embossing Aluminum coil

- Cobblestone Embossed Aluminum roll

- Corrugated Embossed Aluminum Sheet

- 5 Bar Embossed Aluminum Coil

- 3 Bar Embossed Aluminum Coil

- 2 Bar Embossed Aluminum Coil

- Hammer Embossed Aluminum Coil

Important Embossed Aluminum Coil Introduction

Stucco Embossed Aluminum Coil

Processing Technology : Stucco embossed aluminum coils are produced through an embossing technique that applies pressure to the aluminum sheet while it is being embossed to create a stucco-like grain pattern.

Common Applications : Stucco embossed aluminum coils are used in various applications, such as interior and exterior wall cladding, roofing and insulation materials, decoration and protection of building curtain walls, wall panels, ceilings, columns, etc. It can also be used for home decoration, such as suspended ceilings, walls, doors and windows, furniture, electrical shells, etc. It also has functions such as fire prevention, sound insulation, and heat preservation.

- Alloys used : 1050, 1060, 1100, 3003, 3105, 8011

- Concrete examples : interior and exterior cladding, roof panels, insulation panels.

Surface treatment such as anodizing, coating or painting according to customer requirements.

Orange Peel Embossed Aluminum Coil

- Processing technology : The orange peel embossed aluminum coil is produced by the embossing process, and pressure is applied to the aluminum sheet during the rolling process to form a pattern similar to orange peel on the surface.

- Common Applications : Orange peel embossed aluminum coils are used in a variety of applications such as refrigeration, air conditioning and insulation.

- Alloys used : 1050, 1060, 1100, 3003, 3105, 8011

- Specific examples : insulation panels for refrigeration and air conditioning systems, walls and roofs, embossed aluminum panels for refrigerator evaporators are generally orange peel.

Diamond Embossed Aluminum Coil

Diamond embossed aluminum coil is an embossed aluminum coil product with a diamond pattern on the surface. In short, the advantages of diamond embossed aluminum coil such as beauty, corrosion resistance, and easy cleaning make it a ideal material for the field.

- Processing technology : Diamond embossed aluminum coils are produced by diamond embossing process, which applies pressure to the aluminum plate while embossing the aluminum plate to form a diamond pattern.

- Common Applications : Diamond embossed aluminum coils are used in a variety of applications such as flooring, wall panels, and trim.

- Alloys used : 1100, 3003, 3105, 5005

- Specific examples : flooring for trucks and buses, trim for buildings, wall panels for indoor and outdoor applications.

5 Bar Embossed Aluminum Coil

- Processing technology : The 5-bar embossed aluminum coil is produced by pattern rolling technology, in which pressure is applied to the aluminum sheet during the rolling process to form five-bar patterns.

- COMMON APPLICATIONS : Rolls of 5 embossed aluminum are commonly used for flooring, stair treads and trim panels.

- Alloys used : 1050, 1060, 1100, 3003, 5052, 5083

- Specific examples : non-slip floors for trucks and buses, stair treads for commercial buildings, decking for architectural applications.

Hammer Embossed Aluminum Coil

- Processing technology : Hammered aluminum coils are produced by pattern rolling technology, which applies pressure when rolling the aluminum sheet to form a texture pattern similar to the hammered surface.

- Common Applications : Hammer embossed aluminum coils are used in a variety of applications such as trim panels, interior trim, and roofing.

- Alloys used : 1050, 1060, 1100, 3003, 3105, 8011

- Specific examples : decorative panels for commercial and residential buildings, interior decoration for public spaces, roof panels for commercial and industrial buildings.

These specifications may vary according to specific requirements of manufacturers and customers. Always consult the manufacturer to ensure that the embossed aluminum coil meets the specifications required for the intended application.

Embossed aluminum coil surface treatment

No matter what kind of surface, embossed aluminum coils have the advantages of excellent pattern, long-lasting luster, stable anti-corrosion performance, safety and environmental protection.

-

Anodized stucco embossed aluminum coil

Anodized stucco embossed aluminum coils have a corrosion-resistant surface and textured appearance and are commonly used for interior and exterior decoration of refrigerators and cooler systems.

-

Color coated embossed aluminum coil

Color coated embossed aluminum coils feature a vibrant and textured surface finish suitable for roofing, cladding and decking applications.

-

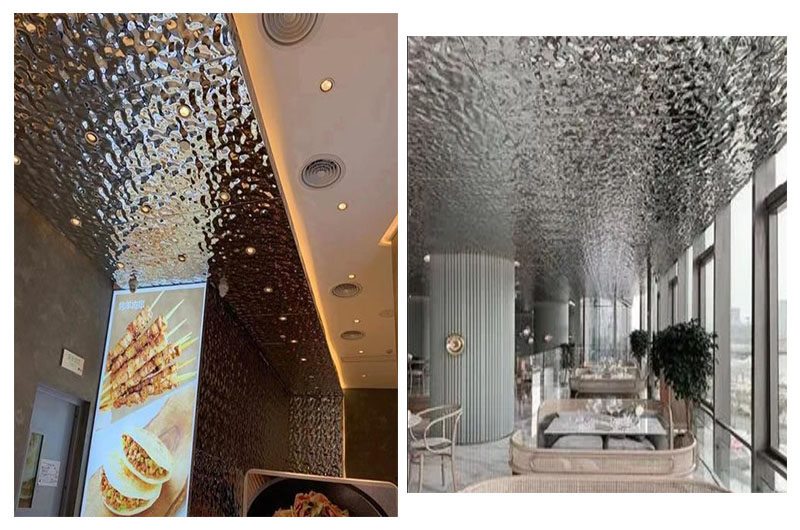

Mirror embossed aluminum coil

Mirror embossed aluminum coils provide a highly reflective surface and are commonly used for decorative elements, signage, and applications requiring a smooth and reflective finish.

-

Kraft paper clad stucco embossed aluminum coil

Kraft covered stucco embossed aluminum coils are designed for transport protection and retain the stucco embossing prior to installation, making them suitable for architectural and interior applications requiring a textured finish.

Haomei Aluminum can provide you with different types of embossed aluminum coils such as 3003 embossed aluminum coil, 1100 embossed aluminum coil, 1060 embossed aluminum coil, etc. There are many aluminum embossed coil manufacturers, and finding a reliable manufacturer can help you reduce a lot of unnecessary Trouble.

Embossed Aluminum Coil Manufacturer Quality

- Surface quality : The surface quality of the embossed aluminum coil is smooth and uniform, without scratches, dents, cracks and other defects. Surface quality affects the appearance, performance and durability of the finished product.

- Texture pattern : The texture pattern of the embossed aluminum coil is consistent, well-defined, and free from blemishes, laces and other defects. Grain patterns can affect the appearance, performance and functionality of the finished product.

- Coating quality : The coating is uniform, free of bubbles, pinholes and other defects, and adheres well to the aluminum surface. The quality of the coating will affect its performance and durability.

It is also important to use proper handling and storage procedures to prevent damage and maintain the integrity of the material. Regular quality checks and inspections also help to ensure that embossed aluminum coils meet the required standards and specifications.

Embossed Aluminum Coil Applications

Haomei Aluminum can supply anodized orange peel embossed aluminum sheets, which are mainly used in cold storage, freezers, color-coated embossed plaster aluminum coils for home appliance panel decoration, roof embossed corrugated sheets, anti-corrosion coated embossed aluminum sheets and pipes for air conditioners, and pattern plates. The pipe is used in mechanical platforms, automobile road anti-skid coil pipe industry, etc.

The following are common applications of embossed aluminum coils :

Building and construction : Embossed aluminum coils are commonly used in building and construction applications such as roofing, cladding and insulation. The raised pattern not only provides a decorative effect but also adds strength to the material.

- Packaging : Embossed aluminum coils are also used in the packaging industry to create decorative and durable packaging materials such as cans, lids and closures.

- Transportation : Embossed aluminum coils are used in a variety of applications in the transportation industry, such as truck and trailer bodies, and interior panels and floors in aircraft and trains.

- Architectural decoration : diamond-shaped embossed aluminum coils are often used for decoration and protection of building curtain walls, roofs, wall panels, ceilings, columns and other parts. It can simulate the texture of rhombus, making the appearance of the building more natural and beautiful.

- Home Appliances : Diamond-shaped embossed aluminum rolls can be used for home appliance shells, such as TVs, refrigerators, microwave ovens, washing machines, etc. It can bring a unique appearance design to home appliances, and it is also anti-corrosion, durable and easy to clean.

Building Decoration

Embossed aluminum coils are commonly used in building and construction applications due to their durability, strength, and decorative appearance. Coil thicknesses for building and construction applications are typically between 0.3 mm and 1.5 mm.

- Alloy : 3003, 3105

- Status : H14, H16, H18, H24

Roof and wall cladding : Embossed aluminum coils are used as roof and wall cladding materials due to their excellent weather resistance and durability. The raised pattern also provides slip resistance, making it suitable for use in areas that require slip resistance.

Insulation : Embossed aluminum coils are used as insulation for pipes and pipes due to their thermal conductivity. The raised pattern also increases the mechanical strength of the material.

Package

Embossed aluminum coils are commonly used in the packaging industry to create decorative and durable packaging materials such as cans, lids and closures. Coil thicknesses for packaging applications are typically between 0.2mm and 0.3mm.

- Alloy : 8011, 3105

- Status : H14, H16, H18

Beverage cans : Embossed aluminum coils are used to make beverage cans due to their light weight, good printability, and corrosion resistance. The raised pattern also increases the mechanical strength of the tank.

Lids and Closures : Embossed aluminum coils are used to make lids and closures for food and beverage packaging because of their ability to create an airtight seal and maintain product freshness.

Transportation

Embossed aluminum coils are used in a variety of applications in the transportation industry, such as truck and trailer bodies, and interior panels and floors in aircraft and trains. Coil thicknesses for transportation applications are typically between 0.5mm and 3.0mm.

- Alloy : 5052, 5083, 5754

- Status : H32, H34, H36, H38

- Truck and Trailer Bodies : Embossed aluminum coils are used to make truck and trailer bodies due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand harsh environments.

- Interior panels and floors : Embossed aluminum coils are used as interior panels and floors in airplanes and trains because they are lightweight, durable and non-slip. The raised pattern also enhances the aesthetics of the material.

Household Appliances

Embossed aluminum coils are used in various applications in the home appliance industry, such as refrigerator and freezer panels, air conditioning and heating systems, and cooking appliances. Coil thicknesses for appliance applications are typically between 0.3mm and 1.5mm.

- Alloys : 1100, 3003, 3105

- Status : H14, H16, H18, H24

Refrigerator and Freezer Panels : Embossed aluminum coils are used in the manufacture of refrigerator and freezer panels because of their ability to withstand low temperatures, humidity and corrosion. The raised pattern also adds strength to the material and improves the appearance of the appliance.

Air Conditioning and Heating Systems : Due to its thermal conductivity, embossed aluminum coils are used as fins and tubes in air conditioning and heating systems. The raised pattern also increases the mechanical strength of the material.

Cookware : Embossed aluminum coils are used to make cookware such as pots and pans due to their excellent thermal conductivity and durability. The raised pattern also provides non-slip properties, making it suitable for cookware.

Embossed Aluminum Coil Chemical Composition

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | 1050 | 1060 | 1100 | 3003 |

|---|---|---|---|---|

| Si | 0.25 | 0.25 | 0.95 Si + Fe | 0.6 |

| Fe | 0.4 | 0.35 | 0.7 | |

| Cu | 0.05 | 0.05 | 0.05~0.20 | 0.05~0.20 |

| Mn | 0.05 | 0.03 | 0.05 | 1.0~1.5 |

| Mg | 0.05 | 0.03 | - | - |

| Cr | - | - | - | - |

| Zn | 0.05 | 0.05 | 0.1 | 0.1 |

| Ti | 0.03 | 0.03 | - | - |

| Others: Each | 0.03 | 0.03 | 0.05 | 0.05 |

| Others: Total | - | - | 0.15 | 0.15 |

| Al: Min. | 99.5 | 99.6 | 99 | remainder |

Embossed aluminum coil process

- Material preparation: First, you need to prepare aluminum coil materials. Generally, coils made of high-purity or high-quality aluminum are selected to ensure the quality and performance of the product.

- Coating treatment: Apply the paint evenly on the surface of the aluminum coil, and use paint spraying to make it evenly adhere to the surface of the aluminum coil to protect and beautify it during embossing.

- Embossing processing: Through a special embossing machine, the aluminum coil is embossed according to the designed pattern and pattern. The embossing machine has a highly precise pattern template and transmission mechanism, which can control the embossing depth and the size and shape of the pattern. and quantity.

- Forming processing: The embossed aluminum coil is subjected to forming processing, including cutting, bending, welding, heat treatment, surface treatment, etc., to finally form the finished aluminum product.

- Quality control testing: During the entire manufacturing process, strict quality monitoring and testing is required to ensure that products meet design requirements and industry standards, while reducing unnecessary waste and costs.