- Anodized Aluminum Coil Specifications

- Anodized Aluminum Coil Characteristics

- Anodized Aluminum Coil Classification

- Anodized Aluminum Coil Common Alloys

- Anodized Aluminum Coil Applications

- Anodizing process

- Anodizing method

- Anodized Aluminum Coil Frequently Asked Questions

Anodized aluminum coils are aluminum coils that have undergone an electrolytic oxidation process that produces a thin protective oxide layer on the surface of the aluminum. The anodizing process increases the thickness and durability of the natural oxide layer, making it more resistant to corrosion, wear and abrasion.

Aluminum coils are anodized to provide corrosion resistance, wear resistance, insulation, adhesion or aesthetics.

Anodized Aluminum Coil is a versatile material with many advantages such as durability, corrosion resistance and aesthetics. Its applications range from building and construction to automotive and transportation, electronics and appliances, and decorative and artistic applications.

Anodized Aluminum Coil Specifications

- Thickness : The thickness of the anodized aluminum coil is usually between 0.2mm and 3.0mm, and the common specifications are 0.5mm, 0.8mm, 1.0mm, etc.

- Width : The width of anodized aluminum coils is usually between 1000mm and 1600mm, and the common specifications are 1220mm, 1250mm, 1500mm, etc.

- Length : The length of anodized aluminum coils is usually determined by customer needs, and can be customized according to different application requirements.

Anodized Aluminum Coil Characteristics

- 1. Durability: Anodized aluminum coils are more durable and longer-lasting than untreated aluminum.

- 2. Corrosion Resistance: Protects aluminum from environmental elements, including moisture and chemicals, and is highly resistant to rust and corrosion.

- 3. Color Stability: For color-coated anodized aluminum, the oxidation helps seal the dye and stabilize the color, reducing fading or discoloration.

- 4. Aesthetics: Anodized aluminum coils have a smooth, satin-like finish that enhances their appearance and are suitable for architectural and decorative applications.

- 5. Low Maintenance: The protective oxide layer on anodized aluminum reduces the need for frequent cleaning or maintenance.

- 6. Electrical Insulation: The oxide layer of anodized aluminum is an electrical insulator, making it suitable for applications where electrical conductivity needs to be limited or controlled.

- 7. Lubricity: Anodized surfaces can exhibit improved lubricity, making them suitable for applications requiring reduced friction.

- 8. Heat resistance: Anodized aluminum coils can withstand relatively high temperatures without losing their protective properties, suitable for applications involving heat exposure.

- 9. Environmentally Friendly: The anodizing process is considered environmentally friendly, does not involve heavy metals or harmful chemicals, and anodized aluminum is fully recyclable.

- 10. Non-toxic: Anodized aluminum is non-toxic and safe for use in a variety of applications, including those that come into direct contact with food or beverages.

Anodized Aluminum Coil Classification

Anodized aluminum coils are available in a wide range of colours, finishes and textures making them suitable for a wide range of applications.

Type by Color

Anodized aluminum coils can be electrolytically oxidized to achieve different colors, common colors include silver white, black, gold, bronze, champagne gold, rose gold, etc. Among them, silvery white is the most common color.

- silvery white anodized aluminum coil

- black anodized aluminum coil

- gold anodized aluminum coil

- bronze anodized aluminum coil

- bronze anodized aluminum coil

- White anodized aluminum coil

- blue anodized aluminum coil

- rose gold anodized aluminum coil

- dark gray anodized aluminum coil

- champagne gold anodized aluminum coil

Type by Surface Treatment

The finish of anodized aluminum coil can be divided into matte surface, high gloss surface, matte surface, pearlescent, brushed, coating and so on.

- Matt surface anodized aluminum coil

- High gloss anodized aluminum coil

- Matte anodized aluminum coil

- Pearlescent anodized aluminum coil

- Brushed anodized aluminum coil

- Coated anodized aluminum coil

- Matte type : the surface presents a matte texture, which is relatively soft.

- High-gloss type : the surface presents a high-brightness texture with high reflectivity.

- Matte type : the surface presents a uniform matte texture, which has a certain anti-fingerprint effect.

- Pearlescent type : the surface presents a texture similar to pearlescent, which has a certain decorative effect.

- Filament type : The surface presents a slender texture, usually used in the field of decoration.

- Coating type : Anodized aluminum is coated with a layer of paint, which can realize various designs of colors and patterns.

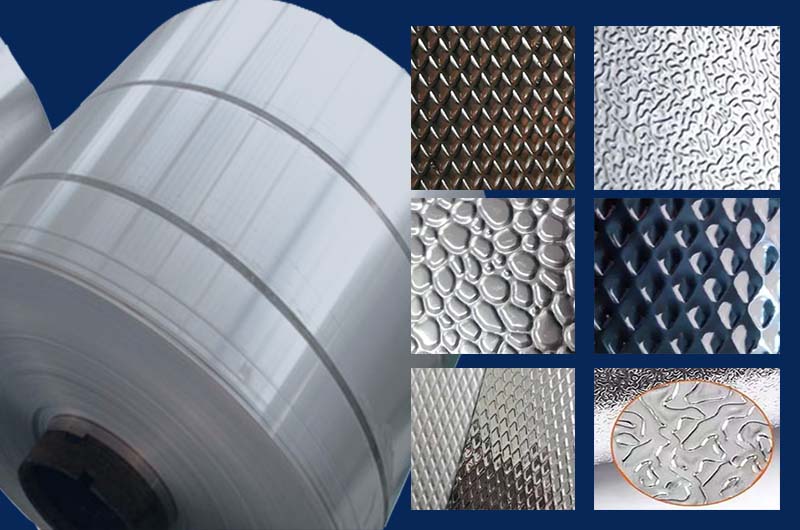

Texture Classification

Anodized aluminum coils can be processed to achieve different texture effects. Common textures include flat, raised, sunken, vertical, water, tree, etc.

- Flat and raised textures are the most common and are suitable for most decorative and industrial applications.

- The depressions and vertical lines have a unique visual effect and are suitable for occasions that need to emphasize layers and three-dimensionality.

- Water patterns and tree patterns have natural and vivid effects, which are suitable for occasions that need to create a natural atmosphere.

The best-selling anodized embossed aluminum coils are as follows:

- Stucco Embossed Anodized Aluminum Coil

- Bean Embossed Anodized Aluminum Coil

- Hammer Embossed Anodized Aluminum Coil

- Water Drop Embossed Anodized Aluminum Coil

- Orange Peel Anodized Embossed Aluminum Coil

- Hemispherical Embossed Anodized Aluminum Coil

- Diamond Embossed Anodized Aluminum Sheet Coil

Anodized Aluminum Coil Common Alloys

The anodizing process can be performed on various aluminum alloys such as 1100, 3003, 5005, 5052 and 6061. The color of anodized aluminum coils can be customized by adding dyes to the electrolyte solution during the anodizing process, resulting in a variety of colors and finishes, including matte, satin and high-gloss.

Alloy Temper Application Example

| Alloy Anodized Aluminum Coil | Temper |

|---|---|

| 1050 Aluminum Coil | H14/H24 |

| 1060 Aluminum Coil | H14/H24 |

| 3003 Aluminum Coil | H14/H24 |

| 5005 Aluminum Coil | H14/H24 |

| 5052 Aluminum Coil | H32/H34 |

1050 Anodized Aluminum Coil

- Application: Interior decoration : wall cladding, ceiling, furniture and cabinets.

- Example: Hotel lobby ceiling, household kitchen cabinets

1060 Anodized Aluminum Coil

- Application: Lighting fixtures : reflectors and lampshades.

- Example: Office LED lampshades, commercial display cabinet lighting

3003 Anodized Aluminum Coil

- Application: Reflective signs : advertising signs and traffic signs

- Example: Road traffic signs, mall advertising signs

5005 Anodized Aluminum Coil

- Application: Solar reflector panels : energy-saving building materials

- Example: Roof solar reflector panels, indoor energy-saving insulation panels

5052 Anodized Aluminum Coil

- Application: Home appliances : rice cooker liner, pressure cooker, oven shell

- Example: Pressure cooker liner, oven shell plate

Compared to other finishing methods, anodizing provides a more durable and long-lasting finish that requires little maintenance. However, it is important to note that the anodized layer can be damaged by abrasion or scratching, exposing the bare aluminum underneath.

Anodized Aluminum Coil Applications

Anodized aluminum coils have a wide range of applications including cladding, roofing and facade systems in the construction industry. It is also used for decorative and ornamental purposes in the automotive industry. Other applications include electronics, furniture and signage.

Anodized Aluminum Coil for Building Decoration

Anodized aluminum coils are commonly used in architectural applications such as cladding, roofing, facades and window frames. The durability and weather resistance of anodized aluminum make it ideal for outdoor use in harsh environments.

- Alloy : 3003/ 6061

- Status : H24/H26

- Thickness : 0.25mm - 3mm

For example, 0.7mm thick, champagne-colored 3003 alloy anodized aluminum coils are used for cladding and roofing of high-end residential buildings.

Anodized Aluminum Coil for Automotive and Transportation

Anodized aluminum coils are used in the automotive and transportation industries for components such as trim, body panels and wheels. The lightweight, strong and corrosion-resistant properties of anodized aluminum make it ideal for improving fuel efficiency and reducing maintenance costs.

- Alloy : 3003 /5052

- Status : H32/ H3

- Thickness : 0.5mm - 2mm

For example, 5052 alloy, 1mm thickness and black anodized aluminum coils are used for trim and body panels in luxury cars.

Anodized Aluminum Coil Electronics and Appliances

Anodized aluminum coils are used for parts such as housings, covers and heat sinks for electronics and appliances. Anodizing provides a layer of protection against scratching, staining and corrosion.

- Alloy : 1100/ 6061

- Status : O /H32

- Range : 0.2mm - 1mm

For example, 1100 alloy, 0.5mm thick and silver anodized aluminum coils are used in the casings of mobile phones and laptops.

Decorative and Artistic Applications

Anodized aluminum coils are also used in decorative and artistic applications such as signage, jewelry and artwork. The range of colors and finishes available makes it suitable for creating unique and visually appealing designs.

- Alloy : 1100/3003

- Status : O/H32

- Thickness : 0.2mm - 1mm

3003 alloy, 0.8 mm thickness and golden anodized aluminum coils for signage and artwork in museums and galleries.

Anodized aluminum coils are used in a wide range of applications and the choice of alloy, temper and thickness depends on the specific requirements of each application. The most commonly used alloys for anodized aluminum coils are 1100, 3003, 5052 and 6061, and the coils are usually in O, H24, H26, H32 or H34 temper, and the thickness varies from 0.2mm to 3mm.

Anodizing process

The anodizing process is generally divided into three main stages, suitable for batch or single-piece production, as well as sheet and coil processing:

1. Preprocessing stage

- Clean the aluminum surface and then chemically treat it.

- A satin-matte look is created by etching, with your choice of light, medium, or heavy etching.

- Bright impregnation is used to enhance the shine of aluminum surfaces and produce varying degrees of reflective finishes.

2. Anodizing stage

- Once the surface is prepared, electric current is passed through the aluminum, which is immersed in an electrolyte bath to form an anodized film.

- Anodized films are made from aluminum itself and have a hard and porous film.

- The coating thickness can be strictly controlled according to the requirements of the final product.

3. Post-processing stage

- At this stage, the porous anodized film can be tinted.

- Use organic dyes to fill the pores with color, or create multiple colors at the bottom of the pores by electrochemically depositing metal salts.

- Many colors are fade-resistant.

- Sealing the anodized film is usually accomplished using a hot water bath, essentially closing the pores by causing them to expand.

Anodizing method

Anodizing methods may have some differences in different situations. The following are the characteristics of three common anodizing methods:

1. Continuous coil anodizing

- Applicable objects: Forming is not too strict, large capacity, roll material, foil products.

- Benefits: Offers a variety of metal and film thickness options, reduces material handling, enables precise color control and uniformity, and is cost-effective.

- Disadvantages: Possible edge issues with stampings, possible cracks on severe forming, sheet and foil only.

2. Plate anodizing

- Usage: Suitable for wide boards and large products.

- Advantages: Suitable for small batch production, thicker film anodized edges can be achieved.

- Disadvantages: Color differences may occur, cost is higher, film thickness differences may exist, cracks may occur during severe molding.

3.Batch or single piece anodizing

- Usage objects: Suitable for extrusion, casting and other products that require strict molding.

- Advantages: Suitable for small batch production, thicker film anodized edges can be achieved.

- Disadvantages: There may be color differences, the processing process is cumbersome and the cost is higher.

Overall, different anodizing methods are suitable for different products and production needs, and the selection of the appropriate method depends on the required material properties, production scale and cost considerations.

Anodized Aluminum Coil Frequently Asked Questions

NO1. Can anodized aluminum coils be colored?

Yes, anodized aluminum coils can be colored using a process called "anodizing and dyeing." In this process, the porous oxide layer created during anodization can be infused with dyes to achieve a variety of colors. The anodized layer helps lock in the dye, ensuring color stability over time.

NO2. Is anodized aluminum coil safe for food contact?

Yes, anodized aluminum is considered safe for direct contact with food and beverages. The oxide layer is non-toxic and inert, making it suitable for applications where food safety is a concern.