- 5456 Marine Aluminum Plate features

- Temper of 5456 Marine Aluminum Plate

- 5456 Marine Aluminum Plate advantages

- 5456 Marine Aluminum Plate Chemical Composition

- 5456 Marine Aluminum Plate Physical Properties

- 5456 Marine Aluminum Plate Applications

- Why Choose 5456 Marine Grade Aluminum Plate for Specific Applications?

5456 ship aluminum plate is a high -quality ship material. It has good advantages such as corrosion resistance, light weight, and high strength, which can meet the needs of ship manufacturing and marine engineering.

5456 aluminum alloy is an aluminum and aluminum alloy material. It often uses anode oxidation treatment and paint method or surface adding aluminum layer to improve corrosion resistance.

5456 aluminum plates for alloy ships are produced in hot -rolled technology, so the anti -fatigue performance and welding performance of the plate are better than that of cast aluminum plates.

Quality fully meets world shipping standards: CCS, DNV, NK, CCS, ABS, BV, LR, Kr.

5456 Marine Aluminum Plate features

- 5456 ship aluminum plates have higher strength than 5086 and 5083. They have similar characteristics, with good mechanical processing and welding.

- 5456 aluminum plate belongs to aluminum -magnesium alloy and has excellent rust resistance. Its performance is similar to the 5083 aluminum plate, but the strength is slightly higher, and the corresponding stress corrosion is sensitive.

- 5456 Marine Aluminum Plate is an aluminum -magnesium rust -proof aluminum plate, which is equivalent to 5A03. It is generally used for structural applications, which can generate high strength in cold processing. When it is stored for a long time at a temperature above 65 ° C, it is prone to peeling and corrosion.

In non -thermal treatment alloys, 5456 aluminum plates have high strength, good welding, corrosion resistance and low temperature performance. Its performance can fully meet the requirements of high welding structures. In addition, the price of 5456 aluminum is very reasonable and helps reduce the cost of shipbuilding.

Temper of 5456 Marine Aluminum Plate

| Temper | Characteristics | Typical Applications |

| 5456 H116 | High strength, excellent corrosion resistance | Ship hulls, marine applications |

| 5456 H321 | Stabilized properties, good strength, corrosion resistance | Marine environments, structural components |

| 5456 H32 | Balanced formability and strength | Decking, structural components |

| 5456 H34 | Higher strength, good plasticity | Armor plates, applications requiring toughness |

| 5456 H112 | Annealed, slightly hardened, good formability | Various applications requiring moderate strength |

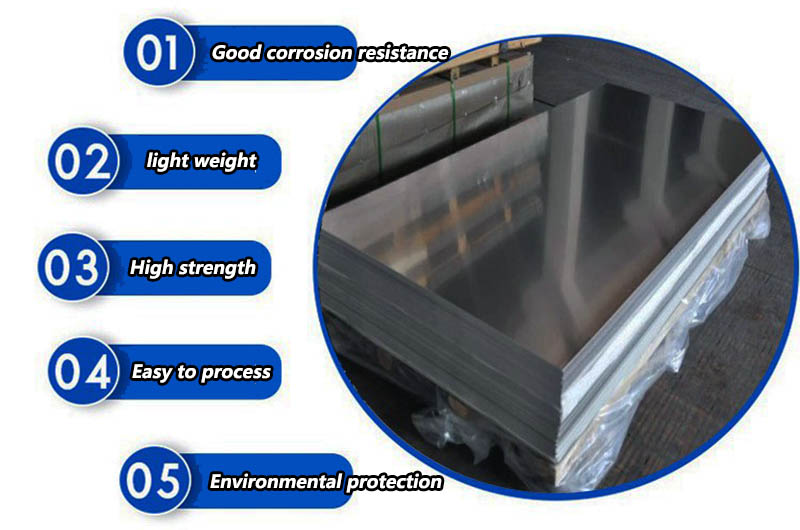

5456 Marine Aluminum Plate advantages

- 1. Good corrosion resistance: 5456 Boat aluminum plates are specially anticorrosive, have good corrosion resistance, and can adapt to bad conditions such as high salt, high humidity, and high temperature in the marine environment.

- 2. Light weight: The density of the 5456 ship's aluminum plate is less density. Compared with traditional steel, it can significantly reduce the weight of the ship, thereby improving the speed and cargo capacity of the ship.

- 3. High strength: 5456 ship aluminum plate has good mechanical properties, and its tensile strength and yield strength are high, which can meet the requirements of the ship structure and supporting parts.

- 4. Easy to process: 5456 ships can be processed by traditional cutting, bending, drilling and other processing methods for shipment, which is convenient and fast.

- 5. Environmental protection: 5456 ship aluminum plates will not produce harmful substances during use, which meets environmental requirements.

- 6. Weldability: 5456 aluminum is weldable, so it is easy to manufacture and create complex structures.

5456 Marine Aluminum Plate Chemical Composition

| Alloy | 5456 | |

|---|---|---|

| Si | ≦0.25 | |

| Fe | ≦0.4 | |

| Cu | ≦0.1 | |

| Mn | 0.50-1.0 | |

| Mg | 4.70-5.50 | |

| Cr | 0.05-0.20 | |

| Zn | ≦0.25 | |

| Ti | ≦0.2 | |

| Zr | - | |

| Standard | EN573 | ASTM B928 |

5456 Marine Aluminum Plate Physical Properties

| Alloy | 5456 | |||

|---|---|---|---|---|

| Temper | O/H111 | H112 | H116/H321 | |

| Tensile Strength | Rm(Mpa) | 285-360 | ≥ 290 | 315-405 |

| Yield Strength | Rp0.2(Mpa) | 125-205 | ≥130 | 230-315 |

| Elongation | A(%) | ≥16 | ≥12 | ≥12 |

| Exfoliation corrosion | - | - | ≦PB | |

| Intergranular corrosion | Mg/cm2 | - | - | ≦15 |

| Certification | CSS | |||

| Standard | EN485, ASTM B928 | |||

5456 Marine Aluminum Plate Applications

5456 shipping aluminum plate is an economic choice for ships. Can be used for hull, deck and other upper accessories.

- 1.5456 aluminum plates are mainly used for ship deck. 5456 aluminum plates with different hardness can meet the special needs of decks in different ships such as living deck, walking deck, and driving deck.

- 2.5456 aluminum plate can be used for the ship's side and will not be corroded for a long time.

- 3.5456 Aluminum is very suitable for the bottom of the ship. 5456 aluminum alloy has high toughness and plasticity, and the plasticity of hull materials can effectively prevent the increase of hull cracks and reduce its hardness. The welding performance of 5456 aluminum plate is better than steel, which is a good choice for shipbuilding.

5456 ships with surface treatment (anode oxidation and coating) are suitable for ships (cargo ships, rowing, electric boats, pedal boats, and cruise ships) in fresh water.

Why Choose 5456 Marine Grade Aluminum Plate for Specific Applications?

5456 marine grade aluminum plate is selected for various shipbuilding applications due to its excellent properties tailored to the demands of marine environments. Here's why 5456 is chosen for specific parts:

5456 Marine Grade Aluminum Plate for Ship Hull

- Reason: 5456 aluminum offers high strength and excellent corrosion resistance, essential for withstanding harsh marine conditions.

- Temper: H116 or H321 temper is typically used, providing a good balance of strength and corrosion resistance.

- Specifications: Common thickness ranges from 4mm to 12mm, with widths up to 2500mm and lengths up to 12000mm.

5456 Marine Grade Aluminum Plate for Deck

- Reason: The low density and high tensile strength of 5456 aluminum make it ideal for decks, which benefit from weight reduction without compromising structural integrity.

- Temper: H32 or H34 temper is common, offering good formability and moderate strength.

- Specifications: Thickness usually varies from 5mm to 15mm, with similar width and length specifications as the hull plates.

5456 Marine Grade Aluminum Plate for Armor Plates

- Reason: 5456 aluminum's high strength and toughness make it suitable for armor plates, providing both protection and durability.

- Temper: H34 or H112 temper is preferred, ensuring high strength and good plasticity.

- Specifications: Thickness can range from 10mm to 50mm, depending on the level of protection required.

5456 Marine Aluminum Plate Specifications Data

| Application Part | Thickness | Width | Length |

| 5456 Marine Grade Aluminum Plate for Ship Hull | 4mm to 12mm | Up to 2500mm | Up to 12000mm |

| 5456 Marine Grade Aluminum Plate for Deck | 5mm to 15mm | Up to 2500mm | Up to 12000mm |

| 5456 Marine Grade Aluminum Plate for Armor Plates | 10mm to 50mm | Up to 2500mm | Up to 12000mm |