- What is 5182 Aluminum Plate, and Why is it Used for Tank Trucks?

- What are the Key Properties of 5182 Aluminum Plate?

- 5182 Tanker Aluminum Plate Advantages

- 5182 Tanker Aluminum Plate Specifications

- Features of 5182 Aluminum for Tanker Cylinders

- 5182 Tanker Aluminum Plate Typical Temper

- Applications of 5182 Alloy in Tanker

- Haomei Aluminum Tanker Aluminum Plate

- Chemical Composition of 5182 Tanker Aluminum Plate

- Mechanical properties of 5182 aluminum sheet plate for oil tanker

- Frequently Asked Questions (FAQs) about 5182 Aluminum Plate for Tank Truck

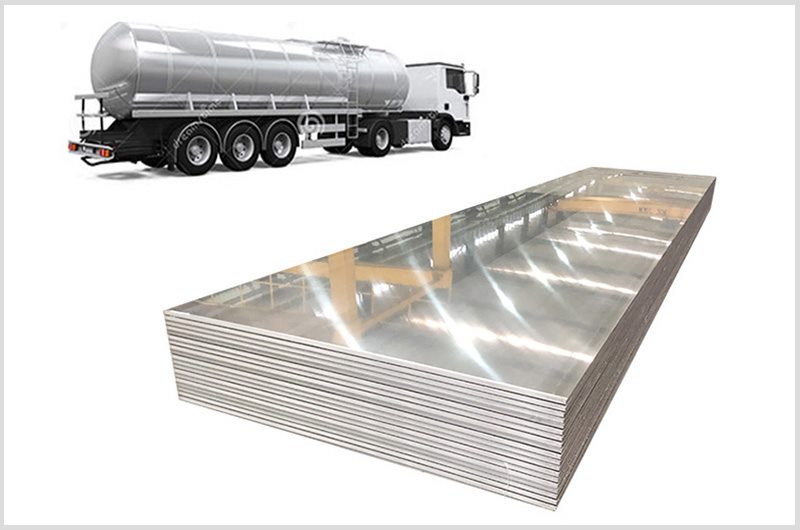

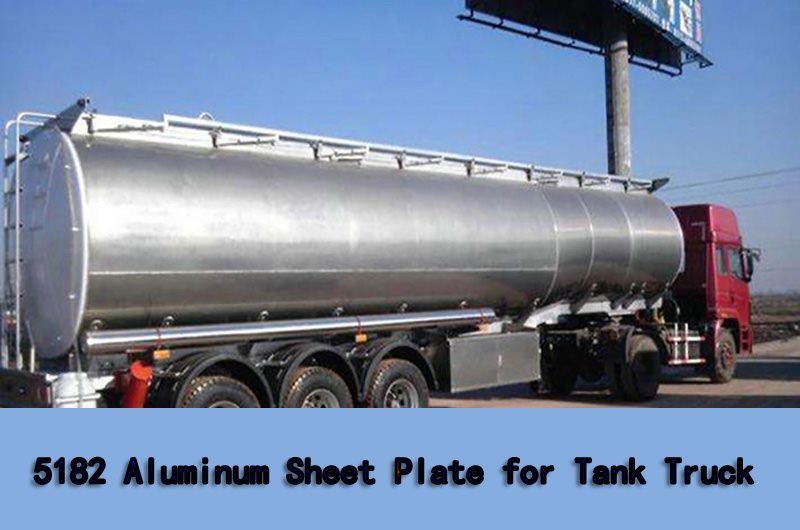

What is 5182 Aluminum Plate, and Why is it Used for Tank Trucks?

5182 aluminum plate is a type of aluminum alloy known for its excellent corrosion resistance and strength. It is commonly used in the construction of tank trucks due to its ability to withstand the corrosive environments and chemicals often encountered in the transportation of liquids and gases.

5182 aluminum plate is a reliable and durable tank truck application material with high strength, corrosion resistance and weldability. Properties such as 5182 aluminum's high strength-to-weight ratio, corrosion resistance, and weldability make it ideal for such applications.

5182 aluminum has excellent resistance to fresh and salt water corrosion, which is important for tank trucks that may carry corrosive liquids or chemicals. The alloy also has good machinability, making it easy to form and form into the configuration required for tanks.

Tank truck manufacturers typically use 5182 aluminum alloy in sheet or sheet form to construct tank truck bodies. Aluminum sheets or sheets are formed into the desired shape and then welded together to form a strong and durable structure. The use of 5182 aluminum makes the tank lightweight and capable of carrying large volumes of liquid or gas.

What are the Key Properties of 5182 Aluminum Plate?

- Outstanding corrosion resistance, particularly in marine and acidic environments.

- High strength, making it suitable for structural components.

- Good formability and weldability.

- High fatigue strength.

- Good workability and machinability.

5182 Tanker Aluminum Plate Advantages

- 5182 Aluminum Plate for Tank Truck is unique in its corrosion resistance, strength and weldability.

- Compared with 5052, 5083 and 5454 aluminum alloys, 5182 aluminum alloy has higher corrosion resistance and oxidation resistance.

- 5182 has good formability and processability similar to 5052.

- 5182 is similar to 5083 and 5454 in terms of strength and weldability.

Therefore, 5182 aluminum alloy is often used in applications such as tanks, fuel tanks, tank trucks, chemical storage tanks, food tanks, etc. that require high strength, corrosion resistance, and weldability.

5182 Tanker Aluminum Plate Specifications

The number and size of 5182 aluminum alloy sheets required to manufacture a complete tank car body are determined by the specific tank car design and size. The body of a tank truck may need to be manufactured using 5182 aluminum alloy sheets of different sizes and thicknesses. Therefore, the number and specifications of 5182 aluminum alloy plates required will vary according to the specific needs of the tanker.

- Thickness : 0.15-600mm

- Width : 20-2650mm

- Length : 500-16000mm

- Standard : ASTM B209, EN 485-2

The size and thickness of the 5182 aluminum alloy sheets used to construct the tank truck body can vary widely depending on the application. Typical dimensions for 5182 aluminum alloy sheets used to build tanker hulls include 4' x 8', 5' x 10' and other standard sheet sizes. Sheet thickness can range from 4mm to 8mm or thicker, depending on specific application requirements.

Features of 5182 Aluminum for Tanker Cylinders

- The aluminum fuel tank made of 5182 aluminum can be 0.5-1mm thinner than the 5083 alloy when the diameter is the same.

- Passed the SGS automotive aluminum quality management system certification.

- The welding performance of gas welding, argon arc welding, spot welding and seam welding is very good.

- Good surface quality. No peeling, air bubbles, rough surface and local mechanical damage.

5182 Tanker Aluminum Plate Typical Temper

5182-O Aluminum Plate for Tanker Trucks

The 5182-O aluminum plate offers excellent plasticity and workability, making it ideal for complex molding and bending. It is commonly used for manufacturing head partitions in tanker trucks, ensuring superior sealing and structural strength.

5182-H111 Aluminum Plate for Tanker Trucks

The 5182-H111 aluminum plate is stabilized, providing high strength and stability. It can withstand mechanical stress and impact loads, making it perfect for the tank structure of oil tankers. Its excellent corrosion resistance helps extend the service life of the tanker truck.

Applications of 5182 Alloy in Tanker

5182 tank truck aluminum plate is a new type of high-magnesium alloy tank truck specially designed for road transportation of dangerous goods in recent years. Its tensile strength and elongation are relatively high, and the excellent quality of 5182 alloy plate improves the safety of aluminum alloy tank cars. 5182 aluminum plate is the main alloy used in tank trucks, high-quality 5182 aluminum plate is the guarantee of transportation safety.

In the current tank car manufacturing industry, the commonly used tank body material is 5182 aluminum plate, whose length does not exceed 12.5 meters, width does not exceed 2.2 meters, and the thickness is mainly between 4mm and 8mm. The tank body of a tank truck usually needs to be composed of 4 to 6 pieces of 5182 aluminum plates.

In general, the thickness and size of the plates used in tank car body construction are determined by application requirements, such as the type of liquid being transported, the size and weight of the tank body, and the regulations applicable to specific regulations.

5182 aluminum plate is commonly used in various components of tank trucks, including:

- Tank bodies and containers.

- Baffles and bulkheads.

- Reinforcements and support structures.

- End caps and closures.

- Access doors and hatches.

5182 H111 Aluminium Plate for Tank Body

The primary application of 5182-H111 aluminum plates in tank trucks is for the tank body itself. These plates are selected for their high strength and stability, capable of withstanding mechanical stress and impact loads. Specifications typically include thicker plates to ensure durability and structural integrity.

5182 alloy can be used to manufacture tanks, which are used in the manufacture of oil tankers, chemical storage tanks, food tanks, compressed natural gas tanks, etc.

Under normal circumstances, the tank body of the tanker will use 5182-H111 aluminum plate, because the 5182 aluminum plate in this state has good formability, weldability and corrosion resistance, which can meet the requirements of the tank body. However, in some special cases, 5182 aluminum sheets in other states may also be used.

5182 O Aluminium Plate for Tanker Head

The 5182 alloy can be used to manufacture the tank cover of the tank car, which is used together with the tank body.

5182 O-state alloy is suitable for applications that require good formability, such as some special-shaped can ends and special-shaped can bodies. O-state alloys have low material hardness and are easy to process and form, so they are widely used in tank car parts that require high formability.

At the same time, due to the good corrosion resistance and welding performance of the 5182-H111 alloy, it is also commonly used in large oil tank trucks and liquid tank trucks for long-distance transportation.

It should be noted that the specific application is also affected by other factors, such as the purpose of the tanker, tank structure, load capacity, etc. Therefore, when selecting the appropriate alloy and state, it is necessary to consider comprehensively according to the actual situation.

5182 O Aluminium Plate for Tank Lids

For the tank lids on both ends, 5182-O aluminum plates are used due to their excellent plasticity and workability. The softer temper of these plates facilitates easier bending during fabrication, ensuring a tight seal and proper fit. Specifications for these parts often involve thinner plates to allow for the necessary forming processes.

5182 O Aluminium Sheet for Tankers Baffle

The baffle within the tank also utilize 5182-O aluminum plates. The choice of this temper allows for complex molding and bending, ensuring strong and secure partitions within the tank. Specifications usually mirror those of the tank lids to maintain consistency in fabrication and performance.

It’s worth noting that some manufacturers may opt for 5454-H111 aluminum plates for tank production, due to their specific material properties and performance characteristics. However, 5182 aluminum plates remain a popular choice for their balance of strength, workability, and corrosion resistance.

5182 Aluminum Plate for Tanker Bottom

The 5182 alloy can also be used to manufacture the tank bottom of the tank car, which bears the weight and pressure of the tank body.

In these applications, the alloy tempers generally used are 5182-H111 or 5182-H32. Among them, the 5182-H111 state has higher strength and corrosion resistance, and is suitable for manufacturing high-demand tank cars. The formability of the 5182-H32 state is better, and it is suitable for the manufacture of parts that require higher formability, such as can bodies and can lids.

Haomei Aluminum Tanker Aluminum Plate

5083, 5454, 5754, 5182, and 5059 are all common aluminum alloys used to make tank car bodies. While they all share some common properties, such as a high strength-to-weight ratio and good corrosion resistance, there are some differences between them that make them better suited for certain applications. Here are some key differences between these alloys in terms of their application in the tanker body :

| Alloy | Strength | Corrosion Resistance |

|---|---|---|

| 5083 Tanker Aluminum Plate | High | Excellent |

| 5454 Tanker Aluminum Plate | Similar to 5083 | Similar to 5083 |

| 5754 Tanker Aluminum Plate | Good | Excellent |

| 5182 Tanker Aluminum Plate | Good | Excellent |

| 5059 Tanker Aluminum Plate | High | Excellent |

Tanker Aluminum Plate Typical Applications

- 5083 Tanker Aluminum Plate : Bottom plates, side walls, and bulkheads of oil tankers and other marine structures

- 5454 Tanker Aluminum Plate : Bends and other formed parts that require good formability and weldability, such as tank bodies

- 5754 Tanker Aluminum Plate : Top of oil tank truck bodies and other structural components in harsh environments

- 5182 Tanker Aluminum Plate : Complex shapes and joints, particularly in marine environments for transporting corrosive liquids

- 5059 Tanker Aluminum Plate : Tank bodies for transporting liquefied natural gas (LNG) or other low-temperature liquids

Selecting an aluminum alloy for a particular application will depend on various factors such as the type of liquid being transported, the size and weight of the tank truck, and the regulations and standards that must be met. It is important to carefully consider these factors and select the appropriate alloy for a particular application.

Chemical Composition of 5182 Tanker Aluminum Plate

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Standard |

| 5182 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | EN573(WT%) |

Mechanical properties of 5182 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| H111 | 3.00-6.00 | ≥280 | ≥125 | ≥24 | ≥6600 | 1.0t |

| >6.00-12.00 | ≥280 | ≥125 | ≥24 | ≥6600 | 2.0t | |

| O | 3.00-6.00 | ≥280 | ≥125 | ≥26 | ≥7280 | 1.0t |

| >6.00-12.00 | ≥280 | ≥125 | ≥26 | ≥7280 | 2.0t |

Frequently Asked Questions (FAQs) about 5182 Aluminum Plate for Tank Truck

Q1: How does 5182 Aluminum Plate Resist Corrosion in Tank Truck Applications?

A1: The corrosion resistance of 5182 aluminum is due to the presence of alloying elements such as magnesium and manganese. When exposed to oxygen, it forms a protective oxide layer on its surface, which acts as a barrier, preventing further corrosion. This characteristic is vital for tank trucks carrying corrosive substances.

Q2: Are there any Special Considerations for Welding or Fabricating 5182 Aluminum Plates for Tank Trucks?

A2: Welding and fabricating 5182 aluminum should be performed with care for optimal results. Recommended welding processes include TIG (tungsten inert gas) or MIG (metal inert gas), along with suitable filler materials. Adequate surface cleaning and preparation are crucial to achieving strong and reliable welds.

Q3: Is 5182 Aluminum Plate Suitable for Transporting Hazardous Materials?

A3: Yes, 5182 aluminum is often chosen for transporting hazardous materials due to its corrosion resistance and reliability. However, it is essential to adhere to all safety regulations and guidelines specific to the transportation of hazardous goods, including proper tank design, fabrication, and maintenance.

Q4: Can 5182 Aluminum Plate be used in Food-grade Tank Trucks?

A4: Yes, 5182 aluminum is suitable for food-grade tank trucks, provided that the material and manufacturing processes comply with food safety and hygiene standards. Ensuring the tank's interior is easy to clean and maintain is essential to prevent contamination.

Q5: What are the Maintenance Requirements for Tank Trucks made from 5182 Aluminum Plate?

A5: Regular maintenance is crucial for tank trucks, regardless of the material used. This includes inspections for signs of corrosion, damage, or wear and tear, as well as proper cleaning and corrosion prevention measures to prolong the tank's lifespan and ensure safe transportation.