- What is Marine Grade 5086 Aluminum Plate?

- Advantages of 5086 Marine Aluminum Sheet

- Marine Grade 5086 Aluminum Plate Specifications

- Commonly Sold 5086 Marine Aluminum Plate

- 5086 Aluminum Plate Sheet Applications for Marine

- 5086 Marine Aluminum Plate Chemical Composition

- 5086 Marine Aluminum Plate Mechanical Properties

- Marine Grade 5086 Aluminum Material

- The Differences Between 5083 and 5086 Marine Aluminum Plate

- Marine Grade 5086 Aluminum Plate Manufacturer

What is Marine Grade 5086 Aluminum Plate?

Marine grade 5086 aluminum is an aluminum alloy specifically designed for marine applications requiring corrosion resistance and high strength. It belongs to the 5xxx series of aluminum alloys, which also includes 5052 and 5083.

5086 aluminum contains magnesium for excellent corrosion resistance and high strength. It also has good formability and weldability, making it easy to process and a popular choice for marine applications.

Some common marine applications for 5086 aluminum include hulls, decks and other structures exposed to salt water and other harsh environments. It is also used in other marine equipment such as gangways, frames and tanks.

Alloy 5086 aluminum plate is even stronger than 5052 or 5083, and its mechanical properties vary greatly with hardening and temperature. Not strengthened by heat treatment; instead, it becomes stronger due to strain hardening or cold working of the material. This alloy can be easily welded and retains most of its mechanical strength.

Advantages of 5086 Marine Aluminum Sheet

| Advantages | Description |

| Lightweight and Excellent Welding Performance | Contributes to reduced weight, lower fuel consumption, and maintenance costs. |

| Low Elastic Modulus | Absorbs large impact stress effectively. |

| No Low Temperature Brittleness | Suitable for use in low-temperature equipment without risk of brittleness. |

| High Recycling Value | Aluminum scrap from 5086 sheet has high recycling value, promoting sustainability. |

| Non-Magnetic Properties | Does not affect compasses, making it suitable for environments sensitive to magnetic interference. |

| High Temperature Performance | Does not deform or burn when exposed to fire, ensuring safety in fire-prone environments. |

5086 Marine aluminum sheet is chosen for applications that require lightweight, durable, non-magnetic, and fire-resistant materials.

Marine Grade 5086 Aluminum Plate Specifications

The specifications, certifications and standards of 5086 marine aluminum sheet can vary according to different needs and regions. Here are some possible specifications, certifications and standards :

Marine Grade 5086 Aluminum Plate Specifications

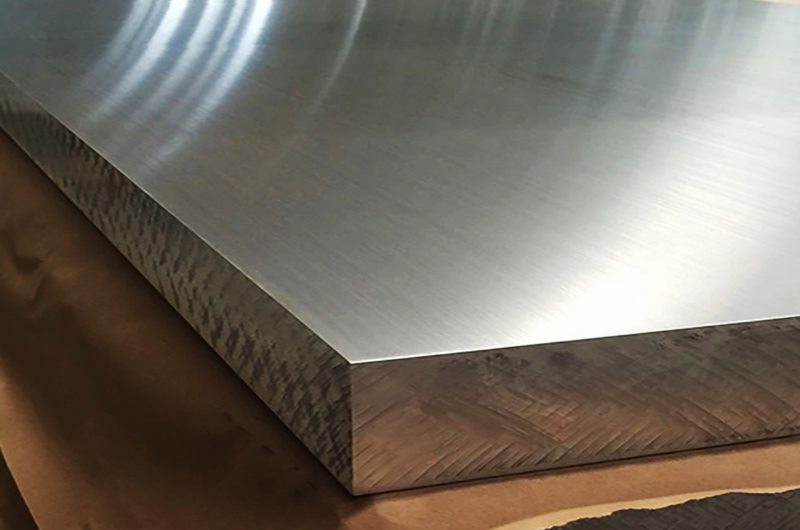

- Thickness : generally ranging from 3mm to 100mm, common ones are 5mm, 6mm, 8mm, 10mm, etc.

- Width : generally ranging from 1000mm to 2500mm, common ones are 1250mm, 1500mm, 2000mm, etc.

- Length : generally ranging from 2000mm to 6000mm, and can also be customized according to customer needs.

Marine Grade 5086 Aluminum Plate Certifications

- ABS certification : ABS is a kind of classification society, and ABS certification is required for aluminum materials used in shipbuilding.

- DNV certification : DNV is a type of Det Norske Veritas, which also certifies aluminum used in ship construction.

- CCS certification : CCS is a kind of China Classification Society, and it will also certify marine aluminum plates.

Marine Grade 5086 Aluminum Plate Standards

- ASTM Standards : Standards developed by the American Society for Testing and Materials.

- EN standard : European standard.

- GB standard : Chinese standard.

It should be noted that different ship construction standards and requirements may have different requirements for the specifications, certifications and standards of marine aluminum plates, so when choosing marine aluminum plates, you need to choose according to the specific situation.

Commonly Sold 5086 Marine Aluminum Plate

5086-H116 Marine Aluminum Plate

It is a heat treatment strengthened alloy with good corrosion resistance and weldability. The thickness usually ranges from 3mm to 50mm, the width ranges from 1000mm to 2600mm, and the length can be customized according to customer requirements.

5086-H111 Marine Aluminum Plate

5087 - This aluminum sheet is a non-heat treatable alloy with high strength and excellent corrosion resistance. The thickness usually ranges from 3mm to 50mm, the width ranges from 1000mm to 2600mm, and the length can be customized according to customer requirements.

These 5086 ship plates are in compliance with ASTM B209 standard and DNV certification.

5086 H321/H116 Marine Aluminum Checkered plate

5086 aluminum alloy checkered plate is usually used in decks, stairs, hatches and other parts of ships. Common specifications are 5086-H112, 5086-H116, etc. Common patterns include fingerprints, Swiss flowers, five stripes, three stripes, etc.

The surface of the aluminum plate has a certain pattern, which can increase the anti-slip effect, and is suitable for occasions such as ship decks, walkways, and anti-skid plates.

The state of 5086 pattern ship plate is generally H116 or H321. The H116 state is a stabilized plate, which has excellent corrosion resistance and strength, and is suitable for seawater environments; the H321 state is a heat-treated and stabilized plate, which can improve the strength and corrosion resistance of the plate. for high-intensity applications.

- 5086-H116 marine aluminum plate : After quenching and stretching treatment, it has good strength and corrosion resistance. It is suitable for ships and ship accessories working in seawater environments, such as decks, hulls, ship beams, cover plates, water tanks, etc.

- 5086-H111 marine aluminum plate : After heating and annealing treatment, it has good processing performance and is suitable for internal structures of ships, steam tanks, ship accessories, etc.

5086 pattern checkered plate : usually in H114 state, the surface has been knurled, with anti-slip performance, suitable for decks, cabins, ship stairs, walking platforms and other ship parts that require anti-slip treatment.

When choosing 5086 aluminum alloy ship plate, it is necessary to consider the specific application and performance requirements to determine which state and surface treatment to choose.

5086 Aluminum Plate Sheet Applications for Marine

The application of 5086 aluminum alloy on ships is similar to that of 5083. It is mainly used in the manufacture of hull structures and other components that require high strength and corrosion resistance. Common applications include hull plating, slipways and other structures.

In specific marine applications, the state and specification of 5086 aluminum alloy will vary according to different application needs. The following are some common applications and corresponding statuses and specifications :

5086 Aluminum Plate Sheet for Hull

- Usually use aluminum plate in 5086-H116 or 5086-H321 state,

- Specifications are generally 4-12mm thickness.

5086 Aluminum Plate Sheet for Slipway

- The slipway is the platform on the lower part of the hull that supports the hull and adds stability.

- The slipway usually uses aluminum plates in the state of 5086-H116 or 5086-H321,

- Specifications are generally 4-12mm thickness.

5086 Aluminum Plate Sheet for Watertight Bulkheads Along the Ship's Sides

- Watertight bulkheads along the sides of the ship are used to isolate different compartments inside the ship to prevent water from pouring into other compartments.

- These bulkheads usually use aluminum plates in the 5086-H321 state,

- The specification is generally 4-8mm thickness.

5086 Aluminum Plate Sheet for Ship Deck

A ship's deck is the superstructure of a ship's hull that supports and covers equipment and cargo inside the ship. Ship decks usually use aluminum plates in the state of 5086-H116,

Specifications are generally 4-12mm thickness.

It should be noted that these are just some common applications and corresponding states and specifications, and the specific usage may vary depending on factors such as ship type, design and requirements.

5086 Marine Aluminum Plate Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Standard |

| 5086 | ≦0.4 | ≦0.5 | ≦0.1 | 0.20-0.70 | 3.50-4.50 | 0.05-0.25 | ≦0.25 | ≦0.15 | - |

EN573 ASTM b928 |

5086 Marine Aluminum Plate Mechanical Properties

| Alloy | Temper |

Rm(Mpa) Tensile strength |

Rp0.2(MPa) Yield strength |

Elongation A(%) |

Exfoliation corrosion |

Intergranular corrosion Mg/cm2 |

Certification |

| 5086 | O/H111 | 240-305 | ≥95 | ≥16 | - | - | DNV, GL, ABS, CCS, BV, LR |

| H112 | ≥250 | ≥125 | ≥8 | - | - | ||

| H116 | ≥275 | ≥195 | ≥10 | ≦PB | ≦15 |

Marine Grade 5086 Aluminum Material

5086 aluminum alloy is often used in ship structures and hulls. Common application forms include :

- Profiles : used for the longitudinal and transverse structures of the hull, such as hull keel, mast base, etc.

- Plates : used for hull and deck coverings, guard plates, etc., as well as structural parts such as internal partitions and warehouse plates.

- Coiled material : It can be used to manufacture pipes, fuel tanks, oxygen cylinders, steam pipes, compressor accessories, etc.

- Checkered plate : used on ship decks, stairs, handrails, etc. to increase the anti-skid performance.

In different application scenarios, the specifications and thickness of 5086 aluminum alloy will also be different. Common specifications include 4x8 feet, 5x10 feet, etc., and the thickness is usually between 0.125 inches and 0.5 inches. In ship structures, the commonly used states of 5086 aluminum alloy are H116 and H321, which can provide good strength and corrosion resistance

The Differences Between 5083 and 5086 Marine Aluminum Plate

| Property | 5083 Marine Aluminum Plate | 5086 Marine Aluminum Plate |

| Chemical Composition | Si: ≤0.4, Cu: ≤0.1, Mg: 4.0-4.9, Zn: 0.25, Mn: 0.40-1.0 | Mg: 3.5-4.5, Zn: ≤0.25, Mn: 0.20-0.7, Ti: ≤0.15, Cr: 0.05-0.25 |

| Mechanical Properties | Tensile Strength: 110-136 MPa | Tensile Strength: ≥240 MPa |

| Elongation: ≥20% | Conditional Yield Strength: ≥95 MPa | |

| Annealing Temperature: 415°C | Elongation (10%): ≥10%, Elongation (5%): ≥12% |

Marine Grade 5086 Aluminum Plate Manufacturer

When the 5086 aluminum alloy is applied to the ship in different forms, its corresponding specifications, thickness and state are as follows :

- Profiles : 5086 aluminum alloy profiles are usually used for hull structures, decks, deck supports and other parts on ships. Common specifications are 5086-H111, 5086-H112, 5086-H116, etc. Common profiles include angle steel, T profile, flat plate, trapezoidal profile, etc.

- Coils : 5086 aluminum alloy coils are usually used for shell panels, guard plates and other parts on ships. Common specifications are 5086-H32, 5086-H34, 5086-H36, etc. The common thickness is 0.2-6mm.

- Checkered plate : 5086 aluminum alloy checkered plate is usually used for decks, stairs, hatches and other parts on ships. Common specifications are 5086-H112, 5086-H116, etc. Common patterns include fingerprints, Swiss flowers, five stripes, three stripes, etc.

- It should be noted that 5086 aluminum alloys of different specifications, thicknesses, and states are suitable for different ship structures, and the specific selection needs to be based on ship structure design requirements and classification society certification.

- 5086 aluminum alloy sheets are usually used for large-area structural parts such as ship hulls and decks. The following are the specifications, thicknesses and states of 5086 aluminum alloy sheets commonly used on ships :

- Specifications : Common specifications include length×width 2400mm×1200mm, 2400mm×1220mm, 2500mm×1250mm, etc. Different specifications can also be customized according to customer needs.

- Thickness : The thickness of the 5086 aluminum alloy sheet is usually between 3mm and 50mm, and different applications require different thicknesses.

- State : 5086 aluminum alloy plates mainly have states such as O, H111, H112, H116, and H321. Among them, the states of H116 and H321 are obtained by heat treatment on the basis of the state of T6, and have higher strength and corrosion resistance. Therefore, in More commonly used on ships.