- What is 5083 Aluminum Plate, and Why is it Used for Tank Trucks?

- What are the Key Properties of 5083 Aluminum Plate?

- 5083 Aluminum for Tank Truck Specifications

- 5083 Tanker Aluminum Plate Typical Temper

- 5083 Aluminum Plate for Tank Truck Applications

- Chemical composition of 5083 aluminum sheet plate for oil tanker

- Mechanical properties of 5083 aluminum sheet plate for oil tanker

- Permissible deviation of 5083 aluminum sheet plate for tanker

- More informations about 5083 aluminum plate tank truck application

- Haomei Aluminum 5083 Aluminum for Tank Truck Quality

What is 5083 Aluminum Plate, and Why is it Used for Tank Trucks?

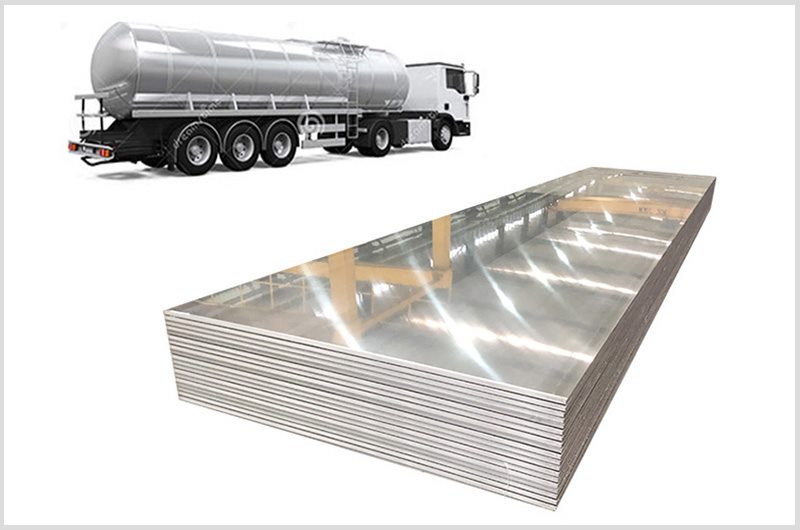

5083 aluminum plate is a high-strength and corrosion-resistant aluminum alloy. It is commonly used in the construction of tank trucks due to its ability to withstand corrosive environments and the chemicals typically encountered in the transportation of liquids and gases.

In tanker applications, 5083 aluminum alloy is usually used to manufacture oil tanks, chemical tanks, etc., because these tanks need to have high strength, high corrosion resistance and excellent welding performance to ensure that the tanks will not be damaged during transportation. There are problems such as cracking and leakage.

5083 aluminum alloy has excellent corrosion resistance and can resist the erosion of various acids, alkalis, salts and other chemical substances, so it can ensure that the tank body will not rust or corrode for a long time.

In addition, 5083 aluminum alloy also has excellent welding performance, which can be easily welded and assembled during the tank manufacturing process to meet the needs of tanks of different shapes and sizes.

5083 aluminum alloy is an ideal material choice for tanker applications, which can meet the requirements of the tank body for high strength, high corrosion resistance and excellent welding performance, and ensure the safety and reliability of the tanker during transportation.

What are the Key Properties of 5083 Aluminum Plate?

- Exceptional corrosion resistance, especially in marine and acidic environments.

- High strength, making it suitable for structural components.

- Good formability and weldability.

- High fatigue strength.

- Excellent workability and machinability.

5083 Aluminum for Tank Truck Specifications

- Thickness : 0.5mm-150mm

- Width : 1000mm-2600mm

- Length : 2000mm-24000mm

- Standards : ASTM B209, EN 485-2, EN 573-3, etc.

-

Tolerance :

- The thickness tolerance is generally ±0.05-0.1mm.

- Length and width tolerances are generally ±2mm.

- Surface flatness tolerance is generally 1-2mm/m.

Specific tolerance requirements may vary due to factors such as production process and application.

When purchasing 5083 tank truck aluminum plates, you can choose products that meet the corresponding standards and tolerance requirements according to actual needs.

5083 Tanker Aluminum Plate Typical Temper

5083 aluminum plate used as tank truck material usually has H111, H112, H116, H321 and other states, among which H111 state is the most common state with good processing performance and corrosion resistance.

5083-O Aluminum Plate for Tanker Trucks

- Advantages: The 5083-O aluminum plate, in its annealed state, offers excellent plasticity, processability, and welding performance.

- Applications: It is commonly used for oil tanker heads and anti-wave baffles due to its ability to be reliably double-sidedly welded with the tank body, ensuring structural tightness and safety.

- Specifications: Often used in thinner gauges suitable for forming and welding processes.

5083-H111 Aluminum Plate for Tanker Trucks

- Advantages: The 5083-H111 aluminum plate has high strength and good plasticity, capable of withstanding impact and vibration.

- Applications: Ideal for the tank truck body, ensuring the integrity and strength of the tanker body.

- Specifications: Generally used in 6mm thickness.

5083-H321 Aluminum Plate for Tanker Trucks

- Advantages: The 5083-H321 aluminum plate is stabilized to resist stress corrosion cracking, making it suitable for high-stress environments.

- Applications: Commonly used for tank body, tank ends and heads, bulkheads and baffles of tank trucks.

- Specifications: Chosen in thicknesses appropriate for parts subjected to stress and corrosion from liquid petroleum products.

5083 Aluminum Plate for Tank Truck Applications

5083 aluminum alloy is mainly used in tank body, tank cover, tank bottom and other parts.

5083 Aluminum Plate for Tanker Body

5083 aluminum alloy is an aluminum alloy with good corrosion resistance and strength, which is often used to make the barrel of aluminum tank cars.

The Tanker Body is the main part of the tanker and also the container for transporting substances, which needs to have high strength and corrosion resistance. Due to its high strength and good corrosion resistance, 5083 aluminum alloy is usually used to manufacture tanks to ensure that the tanks will not crack or leak during transportation.

| Alloy | 5083 H111 | 5083 H32 |

|---|---|---|

| Thickness | 5~10 | 2~6 |

| Tensile strength | 305 MPa | 275 MPa |

| Yield strength | 215 MPa | 125 MPa |

| Elongation at break | 12% | 16% |

| Hardness | 95 HRB | 68 HRB |

Under normal circumstances, the cylinder body of the aluminum tank car adopts the H111 state of the 5083 aluminum alloy. In addition, the H32 state of 5083 aluminum alloy can also be used to manufacture the barrel of aluminum tanker.

5083 H32 aluminum plate for Tanker Body has lower strength and hardness than 5083 H111 aluminum plate for Tanker Body, and 5083 H32 aluminum plate for Tanker Body is suitable for occasions that bear less pressure and load.

Therefore, in general, the H111 state of 5083 aluminum alloy is more suitable for the manufacture of aluminum tank trucks.

5083 Aluminum Plate for Tanker Cover

The can lid is a part used to close the top of the tank body, which needs to have high strength and sealing performance. The high strength and excellent welding properties of 5083 aluminum alloy make it an ideal material choice for tank ends.

| Tanker Cover Type | Application |

|---|---|

| 5083 H111 Aluminum | General liquid transport tanker trucks (e.g. fuel tankers, cleaning tankers, water tankers, etc.) |

| 5083 H116 Aluminum | Special liquid transport tanker trucks with specific requirements (e.g. chemical tankers, hazardous material tankers, etc.) |

| 5083 O Aluminum | Liquid transport tanker trucks that do not require heavy loads and vibration resistance (e.g. food tankers, dairy tankers, etc.) |

The H111 state, H116 state and O state of the 5083 aluminum alloy have the following differences :

5083 H111 Aluminum for Tanker Cover is relatively low in strength and hardness.

5083 H116 : It has high tensile strength and hardness, and is suitable for the manufacture of parts such as tank car lids that need to withstand heavy loads and vibrations. Compared with the H111 state, the 5083 aluminum alloy can lid in the H116 state is stronger and more durable.

5083 O : This is the softened state of 5083 aluminum alloy, which has high machinability and formability. However, compared with the H111 state and H116 state, the O state 5083 aluminum alloy tank cover has lower strength and hardness, and is suitable for some liquid transport tankers that do not need to bear heavy loads and vibrations.

Therefore, for the selection of the tank truck cover, it needs to be selected according to the specific application occasions and requirements, so as to meet the performance and quality requirements of the tank truck tank cover.

5083 Aluminum Plate for Tanker Bottom

The bottom of the tank is the bottom of the tank body of the tanker. It needs to have high strength and corrosion resistance to ensure that the tank body will not break or leak during transportation. 5083 aluminum alloy is usually used to make tank bottoms because of its high strength and excellent corrosion resistance.

The bottom of the tank truck is generally made of 5083 aluminum alloy, and the commonly used states are H111 and H32.

- 5083 H111 Aluminum for Tanker Bottom has good machinability and formability, suitable for tank bottom applications with less stringent requirements.

- 5083 H32 Aluminum for Tanker Bottom is the cold-rolled state of 5083 aluminum alloy, with high hardness and strength, suitable for more demanding tank bottom applications.

It is necessary to select the appropriate 5083 aluminum alloy state according to the specific application requirements and process conditions, and take appropriate measures during the processing to ensure the quality and performance of the tank bottom.

Chemical composition of 5083 aluminum sheet plate for oil tanker

| Element | Composition % |

| Si | 0.40 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.40-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.15 |

| Al | Remainder |

Mechanical properties of 5083 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| O, H111 | 3.00-6.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 1.5t |

| >6.00-12.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 4.0t | |

| H116 | 3.00-6.00 | 305-370 | ≥220 | ≥12 | - | 3.0t |

| >6.00-12.00 | 305-370 | 220 | ≥12 | - | 6.0t | |

| H321 | 3.00-6.00 | 305-370 | ≥220 | ≥l2 | - | 3.0t |

| >6.00-12.00 | 305-370 | ≥220 | ≥12 | - | 6.0t |

Permissible deviation of 5083 aluminum sheet plate for tanker

| Thickness (mm) | Thickness tolerance in different width ranges(mm) | ||||

| > | ≤ | W≤1250 | 1250<W≤1600 | 1600<W≤2000 | 2000<W≤2500 |

| 3.0 | 6.0 | +0.320 | +0.320 | +0.400 | +0.450 |

| 6.0 | 8.0 | +0.380 | +0.460 | +0.500 | +0.600 |

| 8.0 | 12.0 | +0.450 | +0.560 | +0.650 | +0.800 |

More informations about 5083 aluminum plate tank truck application

- Petrochemical Industry : 5083 aluminum tank truck can be used to transport various chemical liquids, such as acid, alkali, salt, ammonia water, ethylene glycol, etc.

- Fuel Industry : 5083 aluminum tank trucks can be used to transport various fuels, such as gasoline, diesel, liquefied petroleum gas, natural gas, etc.

- Food and Beverage Industry : 5083 aluminum tank trucks can be used to transport various foods and beverages, such as milk, juice, alcohol, etc.

- Agricultural Industry : 5083 aluminum tank trucks can be used to transport various pesticides, fertilizers and other liquid agricultural products.

- Other Industries : 5083 aluminum tank trucks can also be used to transport various liquid products such as water, lubricating oil, and detergent.

5083 Aluminum Plate for LNG Storage Tanks

Natural gas must be stored at a very low temperature of -162°C to remain liquefied. Liquefied natural gas (LNG) has a significantly reduced volume, about 1/600th of its gaseous state, which necessitates the use of materials that can withstand such extreme conditions.

Why choose 5083 aluminum plate for LNG Storage Tanks?

- Exceptional Low-Temperature Performance: 5083 aluminum maintains its strength and ductility at very low temperatures, making it ideal for LNG storage.

- High Strength-to-Weight Ratio: The lightweight nature of aluminum, combined with its high strength, ensures that the storage tanks are both durable and efficient.

- Corrosion Resistance: Excellent resistance to corrosion, especially in marine environments, ensures the longevity and safety of LNG storage tanks.

Temper and Specifications

- Temper: Typically, 5083 aluminum in the H321 or H111 temper is selected for LNG storage tanks due to its optimal balance of strength and ductility.

- Specifications: Available in various thicknesses to meet the structural requirements of storage tanks, ensuring they can handle the pressure and environmental conditions.

5083 Aluminum Plate for Fuel Tankers

Fuel tankers benefit greatly from the use of 5083 aluminum due to its low density and high strength. Compared to steel tankers, aluminum tankers are significantly lighter, which leads to various operational advantages.

Why choose 5083 aluminum plate for Fuel Tankers?

- Fuel Efficiency: The reduced weight of aluminum tankers translates to lower fuel consumption and less tire wear during transportation, cutting down on daily operating and maintenance costs.

- Extended Service Life: 5083 aluminum's strong corrosion resistance ensures that the tankers have a longer service life, even when exposed to harsh environments.

- High Recovery Rate: Aluminum is highly recyclable, meaning that tankers made from 5083 aluminum have a high recovery rate, contributing to environmental sustainability.

Temper and Specifications

Temper: Commonly, 5083 aluminum in the H111 or H321 temper is used for fuel tankers due to its excellent balance of strength and formability.

Specifications: Available in different thicknesses to meet the structural and safety requirements of fuel tankers.

Haomei Aluminum 5083 Aluminum for Tank Truck Quality

5083 aluminum alloy is a material commonly used in tank car manufacturing, and its sheet quality is critical to the performance and safety of tank cars.

- Surface quality : Haomei Aluminum strengthens the surface cleaning and protection of 5083 aluminum sheets during the production process, and strictly controls product quality control.

- Dimensional deviation : strengthen dimensional control and adjustment during the production process, adopt advanced processing technology and equipment, and strictly implement relevant standards and specifications.

- Composition and performance : Strengthen the selection and quality control of raw materials, implement relevant standards and specifications, and strictly inspect and test the composition and performance of 5083 plates.

The quality of 5083 aluminum sheets provided by different manufacturers and suppliers may vary, so full investigation and evaluation are required when selecting suppliers to ensure that the quality of aluminum sheets meets the standards and requirements, thereby ensuring the performance and safety of the tanker.