- Why choose 5059 aluminum plate for ship plate?

- Specifications of 5059 Marine Aluminum Plate

- Advantages of 5059 Marine Grade Aluminum Plate Sheet

- 5059 Marine Aluminum Plate Composition and Properties

- Chemical Composition of Marine Grade Aluminum Plate 5059

- Mechanical Properties of Marine Grade 5059 Aluminium

- Marine Grade 5059 Aluminum Plate Sheet Applications

- Marine Grade 5059 Aluminum Fabrication and Weldability

Marine grade 5059 aluminum plate is a specialized alloy designed for marine applications and is known for its exceptional corrosion resistance, high strength and excellent weldability.

5059 marine aluminum plate belongs to the 5 series aluminum-magnesium alloy and is commonly used in marine engineering. 5059 aluminum alloy can be used from ships of tens or hundreds of tons to ships and cruise ships of tens of thousands of tons.

The performance of 5059 alloy is better than that of 5083 alloy. However, due to its higher magnesium content, its pressure processing and forming capabilities are slightly inferior to those of 5083 alloy. Generally speaking, 5059 has better mechanical properties and corrosion resistance than 5083 marine grade aluminum and can be used as a replacement for 5083.

Why choose 5059 aluminum plate for ship plate?

Using 5059 aluminum alloy plates instead of conventional steel plates as the hull material can not only reduce the weight of the hull, but also make up for the problem of steel plates failing due to corrosion during use.

- 5059 aluminum plate with low density and high tensile strength

- 5059 aluminum has strong resistance to seawater and marine climate corrosion

- good welding performance

- Non-magnetic, good low temperature performance

Specifications of 5059 Marine Aluminum Plate

| Alloy | 5059 |

|---|---|

| Alloy | 5059 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H32, H34, H111, H114, H26, H28, H112 |

| Thickness(mm) | 3-50 |

| Width(mm) | 2000 or customized |

| Length(mm) |

6000/8000/9000/12000mm Or customized |

| Applications | Yachts, cruise ships, cargo ships, fishing boats, etc. |

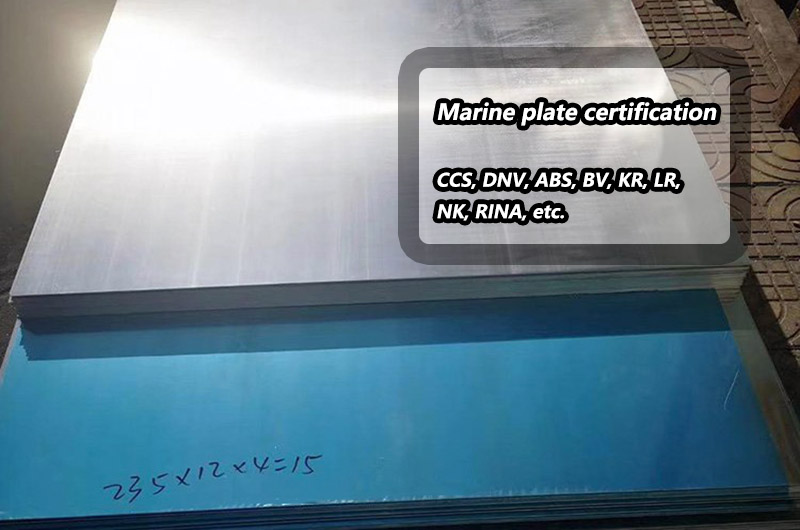

| Certifications | CCS, DNV, ABS, BV, KR, LR, NK, RINA |

| Alloy | Temper | Thickness (mm) | Width (mm) |

|---|---|---|---|

| 5059 | O/H111/H112/H116/H321 | 3-10 | ≤2600 |

| 5059 | H112 | 10-50 | ≤3600 |

Advantages of 5059 Marine Grade Aluminum Plate Sheet

| Property | Description |

| High Strength | 5059 marine grade aluminum plate sheet exhibits exceptional strength, meeting the rigorous demands of ship structures. Its high strength enables it to endure the stresses and loads encountered during voyages and offshore operations. |

| Excellent Corrosion Resistance | This alloy offers outstanding resistance to corrosion in marine environments, effectively shielding against the damaging effects of saltwater and humidity. It enhances the longevity of the hull and extends maintenance intervals. |

| Lightweight Design | Compared to traditional steel plates, 5059 aluminum sheet has a lower density, contributing to lightweight ship designs. This reduction in overall vessel weight improves fuel efficiency and enhances overall sailing performance. |

| Ease of Processing | 5059 aluminum sheet is highly processable, allowing for cutting, bending, welding, and shaping as needed. Manufacturers can customize hull structures more flexibly, accommodating specific design requirements. |

| Excellent Welding Performance | The alloy exhibits excellent welding characteristics, accommodating various welding methods with ease. This facilitates a smoother manufacturing process while ensuring strong and reliable welded joints. |

5059 Marine Aluminum Plate Composition and Properties

1. Alloy composition

Marine grade 5059 aluminum plate belongs to the 5xxx series aluminum alloy. The main component is aluminum, with a large amount of magnesium and a small amount of chromium added.

2. Corrosion resistance

The alloy is known for its excellent corrosion resistance in marine environments, making it ideal for applications exposed to salt water and harsh weather conditions.

3. Strength and toughness

Marine Grade 5059 has high strength and good toughness. This combination of properties makes it suitable for structures requiring structural integrity and durability in challenging marine conditions.

Chemical Composition of Marine Grade Aluminum Plate 5059

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Standard |

| 5059 | ≤0.45 | ≤0.5 | ≤0.25 | 0.6-1.2 | 5.0-6.0 | ≤0.25 | 0.4-0.9 | ≤0.2 | 0.05-0.25 | EN573 ASTM B928 |

Mechanical Properties of Marine Grade 5059 Aluminium

| Alloy | Temper | Tensile strength Rm(Mpa) | Yield strength Rp0.2 (Mpa) | Elongation A (%) | Exfoliation corrosion mg/cm2 | Intergranular corrosion | Standard |

| 5059 | O/H111 | ≥330 | ≥160 | ≥24 | - | - | EN/ ASTM |

| 5059 | H112 | ≥330 | ≥160 | ≥20 | - | - | |

| 5059 | H116/H321 | ≥370 | ≥270 | ≥10 | ≤PB | ≤15 |

Marine Grade 5059 Aluminum Plate Sheet Applications

1. Marine Grade 5059 Aluminum Plate for shipbuilding industry

One of the main applications for marine grade 5059 aluminum is in the shipbuilding industry. Due to its corrosion resistance and lightweight properties, it is used to manufacture various components of ships, including hulls, decks and superstructures.

2. Marine Grade 5059 Aluminum for offshore structures

The alloy is widely used on offshore platforms and structures that are frequently exposed to salt water. Its corrosion resistance and strength make it an excellent choice for components such as decks, walkways, and support structures.

3. 5059 Aluminum for marine equipment

Marine grade 5059 is used in the construction of marine equipment such as ship fittings, navigation towers and other accessories. Its durability and corrosion resistance help extend the life of marine components.

Marine Grade 5059 Aluminum Fabrication and Weldability

5059 aluminum plate is a non-heat treatable strengthened aluminum alloy. The main strengthening method is work hardening. The processing technology generally includes hot rolling, cold rolling and other processes after smelting to achieve H116 tempering to meet the corrosion resistance of the alloy.

1. Weldability

Marine grade 5059 aluminum plate is famous for its excellent weldability. It has good welding performance and is not easy to crack and deform after processing. This characteristic allows complex structures to be easily manufactured and constructed through the welding process.

2. Mechanical processability

5059 aluminum alloy is machinable, allowing components to be precision machined, contributing to its versatility in a variety of applications.

Marine grade 5059 aluminum plate is a reliable and durable material in marine and corrosive environments. Its composition provides high corrosion resistance, strength and weldability, making it the first choice for a range of applications including shipbuilding, offshore structures, marine equipment and chemical processing.

As technology continues to advance, demand for such specialty alloys is expected to grow, further establishing marine grade 5059 as a cornerstone of marine engineering and related industries.

Haomei Aluminum is an aluminum plate manufacturer specializing in the production of marine aluminum plates, providing 5059 marine aluminum plates, 5059 tank car aluminum plates, 5059 medium-thick aluminum plates, 5059 extra-wide aluminum plates, 5059 alloy aluminum plates, etc. The product not only has good shape, smooth and delicate surface, and small thickness tolerance. The product models are complete and can be customized according to customer needs, with fast delivery and large output. Exported to many overseas countries and regions, after-sales service is guaranteed.