- 5 Bar Aluminum Tread Plate Specification

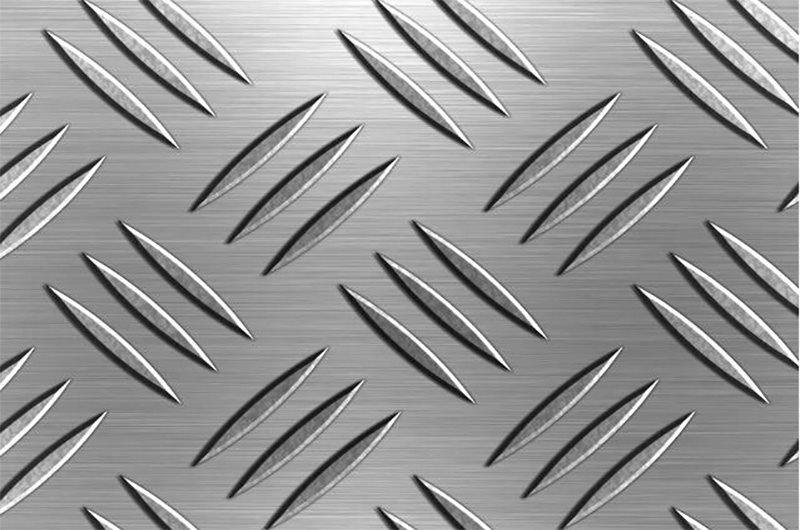

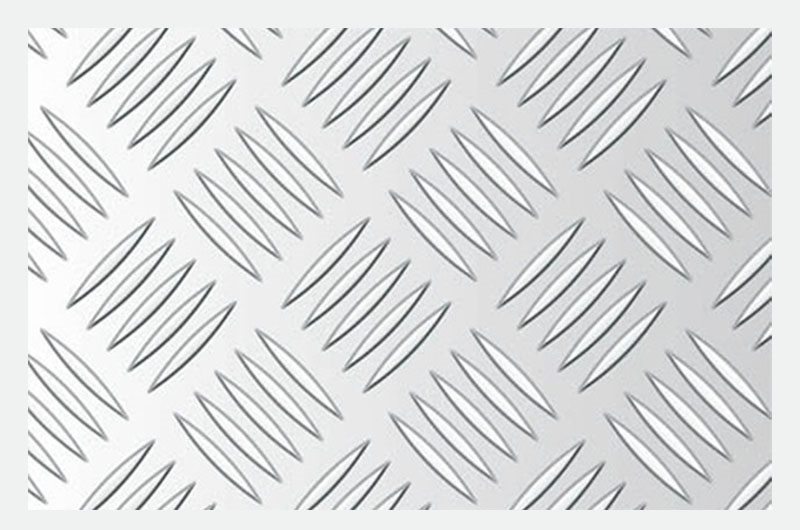

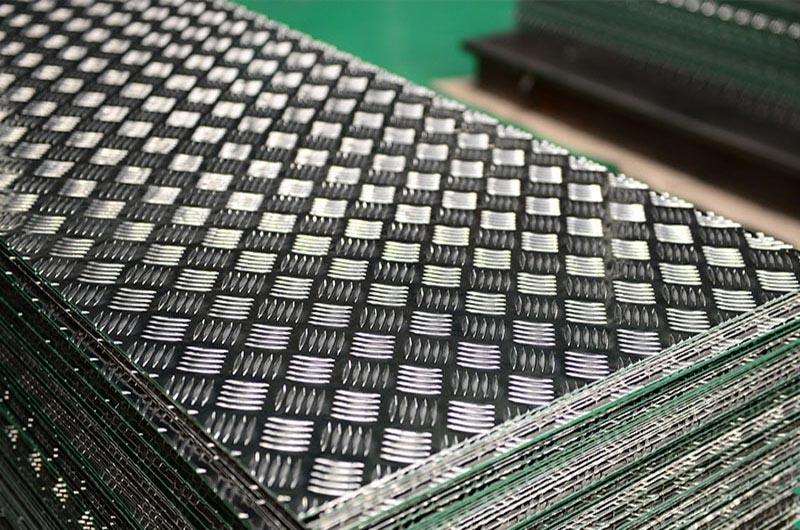

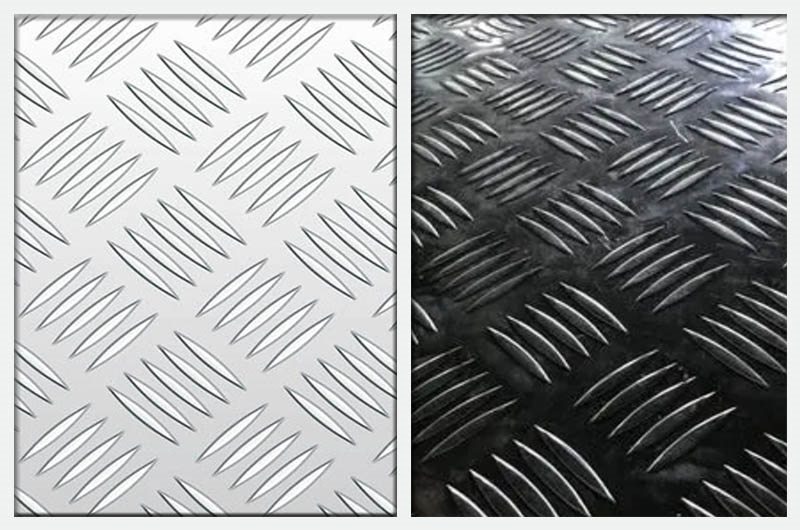

- 5 Bar Aluminum Plate Surface Type

- Typical 5 Bar Aluminum Tread Plate

- 5 Bar Aluminum Tread Plate Application

- How to Choose Aluminum Tread Plate

The 5 bar aluminum tread plate, also known as aluminum checker plate or aluminum diamond plate, is an aluminum plate with raised lines or diamond patterns on the surface. It is usually made of aluminum alloy 3003, 5052 or 6061 and comes in various thicknesses and sizes.

The raised pattern on the surface of the patterned aluminum sheet provides slip resistance and traction, making it ideal for use on floors, stairs, ramps and other applications requiring a non-slip surface. It is also commonly used in truck beds, tool boxes and trim

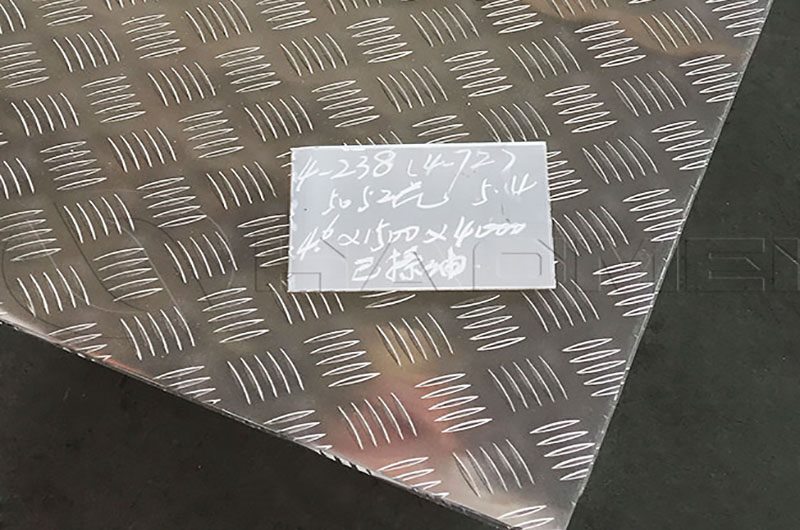

5 Bar Aluminum Tread Plate Specification

Specifications for 5-bar aluminum pedals vary depending on the specific alloy, condition and application requirements. Here are some general specifications for 5-bar aluminum pedals :

- Alloys : The most commonly used alloys for 5 bar aluminum pedals are 3003, 5052, 4017 and 6061.

- Condition : Aluminum pedals can be obtained in tempers ranging from annealed (O) to fully hardened (H18).

- Thickness : The thickness of the patterned aluminum plate can vary from 1.0mm to 6.0mm, depending on the application requirements and load requirements.

- Width and Length : Aluminum treads can vary in width and length depending on application requirements, but standard sizes are typically 4' x 8' or 5' x 10'.

- Standards : The most common standards for 5-bar aluminum pedals are ASTM B209, EN 573-3 and JIS H4000.

- Surface treatment : The surface of the aluminum pedal can be coated or painted to improve its wear resistance or enhance its appearance.

These specifications are general and may vary based on specific application requirements and customer preferences. Therefore, it is important to consult

5 Bar Aluminum Plate Surface Type

Mill Finish Aluminum Tread Plate

Mill finish This is the most basic surface treatment, where the sheet is simply rolled and cooled to its final shape. The finish is rough and matte, not as smooth or shiny as other treatments.

- Common alloys : 3003, 6061

- Alloy State : H22, which offers a good balance of strength and formability.

- Common Applications : Polished aluminum treads are commonly used in industrial and commercial applications where durability and slip resistance are important, such as floors, loading ramps, and stair treads.

Anodized Aluminum Diamond Plate

Anodizing forms a thin protective layer on the aluminum surface. This layer can be dyed to produce a range of colors and provides additional protection against corrosion and wear.

- Common alloys : 3003, 5052

- Alloy state : H14, with good formability and corrosion resistance.

-

Color : Various colors are available

- black aluminum diamond plate

- diamond tread aluminum sheet in silver

- Common Applications : Anodized Aluminum Diamond Sheet is commonly used in architectural and decorative applications, and in high traffic areas where slip resistance is important. It is also used in marine environments due to its corrosion resistance.

Powder Coating Aluminum Tread Plate

Powder coating involves spraying a dry powder onto an aluminum surface and then baking it to create a durable, decorative finish. It is available in a variety of colors and can be customized to meet specific design requirements.

- Common alloys : 3003, 5052

- Alloy state : H22, which provides a good balance of strength and formability.

- Common Applications : Powder-coated aluminum treads are commonly used in architectural and decorative applications, and in high-traffic areas where slip resistance is important. It is also used in marine environments due to its corrosion resistance.

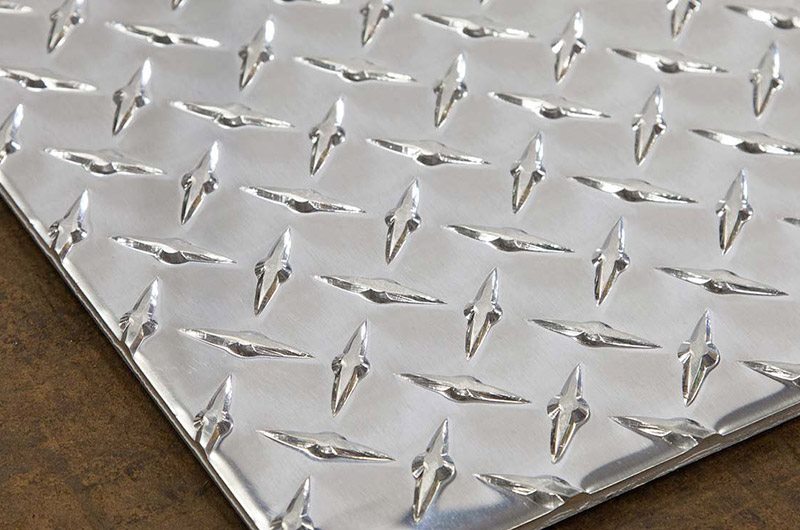

Polished Aluminum Tread Plate

Polishing produces a high gloss finish. Often used in decorative applications, this treatment can enhance the appearance of the diamond pattern on the board.

- Common alloys : 3003, 6061

- Alloy state : H22

- Common Applications : Polished aluminum pedals are commonly used in architectural and decorative applications, as well as high-end automotive and marine environments. It is also used in jewelry and furniture design due to its high reflectivity.

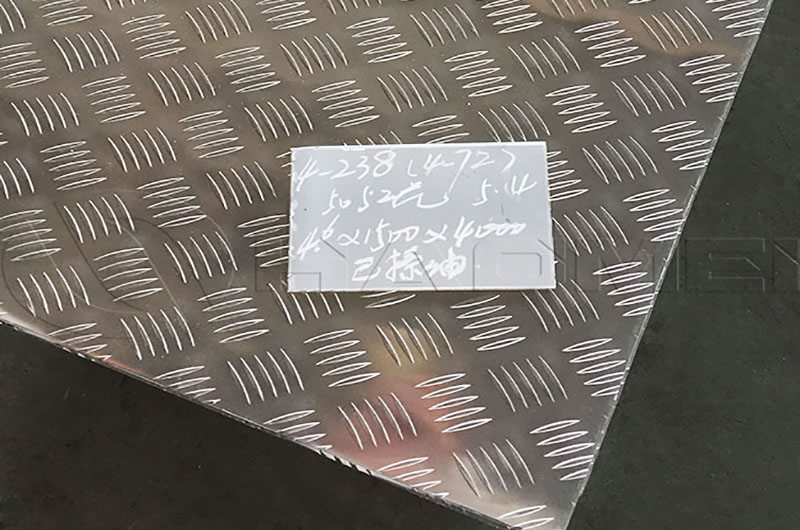

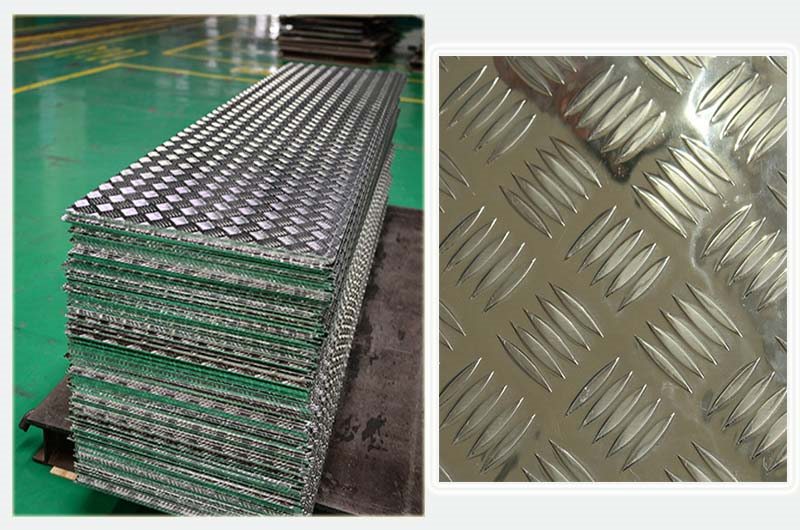

Typical 5 Bar Aluminum Tread Plate

5 Bar 3003 Aluminum Tread Plate

- Corresponding applications : General applications such as floors, stairs and decorative parts.

- Advantages : lightweight, durable, corrosion-resistant. Easy to manufacture with good formability. High cost performance.

- Status : H22

- Specification : ASTM B209

3003 Aluminum is ideal for applications requiring a lightweight and cost-effective material with good formability and corrosion resistance. 5 Bar 3003 Aluminum Tread Plate is a suitable choice for indoor or outdoor use with moderate flow and abrasive requirements.

5 Bar 5052 Aluminum Tread Plate

- Compatible Applications : Heavy-duty applications such as truck beds, tool boxes and industrial floors.

- Advantages : It is stronger than 3003 and can bear heavy loads. Corrosion resistant and easy to weld.

- Status : H32

- Specification : ASTM B209

5052 Aluminum Tread Plate is the best choice for heavy duty applications requiring a durable material with excellent corrosion resistance. The 5 Bar 5052 Aluminum Tread Plate is suitable for harsh environments with heavy loads and high foot traffic.

5 Bar 4017 Aluminum Tread Plate

- Corresponding applications : commercial vehicle floors, industrial floors, stair treads.

- Advantages : Compared with 3003 and 5052, it has higher strength and better fatigue resistance. Excellent corrosion resistance. Reduced maintenance costs due to reduced wear.

- Status : H22

- Specifications : EN 573-3, ASTM B209

4017 Aluminum Tread Plate 4017 aluminum is a good choice for commercial and industrial applications that require a material with higher strength and better fatigue resistance than 3003 and 5052. 5 Bar 4017 Aluminum Tread Plate offers excellent corrosion resistance and reduces maintenance costs due to reduced wear.

4' x 8' Aluminum Tread Plate

The 4' x 8' size may be better for smaller projects or applications that require a more manageable size and weight of the board. It may also be more cost-effective due to its smaller size.

- Alloy : 3003-H22

- Pattern : 5 bar, 2 bar

Common applications

- Flooring for motorhomes, trailers and garages

- Stair Treads and Risers

- Toolboxes and Toolboxes

- Decoration of homes and commercial buildings

- Truck Chassis and Tailgates

- Wall coverings in commercial kitchens and other industrial environments

5' x 10' Aluminum Tread Plate

The 5' x 10' size may be better for larger projects or applications that require larger paper. It can cover larger areas without seams, which improves the appearance and durability of the installation.

- Alloy : 3003-H22

- Pattern : 5 bar, 2 bar

Common applications

- Flooring in industrial environments and high traffic areas

- Wall panels in commercial kitchens and other industrial environments

- Trailer floors and ramps

- Truck chassis and trailer sides

- Trim parts for cars, boats and other vehicles

- Industrial Tool Boxes and Storage Cabinets

5 Bar 6061 Aluminum Tread Plate

- Corresponding applications : structural applications such as stairs, ramps, and platforms.

- Advantages : Heat treatable for strength and durability. Excellent corrosion resistance. Easy to weld and machine. Anodizing can be done for added surface protection.

- Status : T6

- Specification : ASTM B209

6061 aluminum is a suitable choice for structural applications requiring high strength, durability and good corrosion resistance. 5 Bar 6061 Aluminum Tread Plate is ideal for heavy duty applications such as stairs, ramps and platforms and can be heat treated for strength and durability.

5 Bar Aluminum Tread Plate Application

5 Bar Aluminum Floor Plate

5 bar aluminum tread plate is commonly used as flooring material in industrial environments such as factories, warehouses and garages where a non-slip surface is required for safety.

- Alloy : 3003-H22 or 5052-H32

- Status : H22 or H32

- Specification : ASTM B209

- Pros : Both alloys are lightweight, durable and corrosion resistant. The H22 and H32 tempers provide good formability and ease of fabrication, while the 5052-H32 alloy provides higher strength for heavier loads.

5 Bar Aluminum Tread Plate for Stairs and Ramps

5 Bar Aluminum Treads Sheet is used as a non-slip material for stairs and ramps, providing traction and reducing the risk of slipping.

- Alloy : 3003-H22 or 6061-T6

- Status : H22 or T6

- Specification : ASTM B209

- Pros : Both alloys offer good slip resistance and traction, with the 6061-T6 alloy offering higher strength for structural applications.

5 Bar Aluminum Treads Sheet for Trailer and Truck Bed Flooring

5052 Aluminum Treads Sheet is commonly used as a flooring material for truck beds and trailers due to its durability and ability to withstand heavy loads.

- Alloy : 5052-H32

- Status : H32

- Specification : ASTM B209

- Pros : 5052-H32 alloy is strong and durable enough to withstand heavy loads. It is also easy to weld and corrosion resistant.

5 Bar Aluminum Diamond Plate Toolboxes

Aluminum Diamond Plate is used as the housing material for the toolbox, providing a durable and corrosion-resistant surface that can withstand harsh environments.

- Alloy : 3003-H22 or 5052-H32

- Status : H22 or H32

- Specification : ASTM B209

- Pros : Both alloys offer durable and corrosion-resistant surfaces that can withstand harsh environments. The H22 and H32 tempers offer good formability and ease of fabrication.

3003 Aluminum Checker Plate for Decorative

Aluminum Checker Plate is used as decorative trim on vehicles, boats and buildings to add a visually appealing diamond pattern to the surface.

- Alloy : 3003-H22 or 6061-T6

- Status : H22 or T6

- Specification : ASTM B209

- Advantages : Both alloys provide a visually appealing diamond pattern on the surface, while the 6061-T6 alloy provides increased strength for structural applications.

How to Choose Aluminum Tread Plate

Selecting the proper 5 bar aluminum tread depends on several factors such as intended application, environmental conditions, load requirements and budget. Here are some factors to consider when choosing the right 5 bar aluminum pedals :

- Application : Determine the specific application in which the aluminum pedal will be used. Consider factors such as the type of traffic or loads it will carry, the required slip resistance, and expected wear and tear.

- Environment : Consider the environmental conditions in which the aluminum pedal will be installed, such as temperature, humidity, and exposure to chemicals or salt water.

- Alloys : Select the appropriate alloy that suits the requirements of the application. 3003, 5052, 4017 and 6061 are the most commonly used alloys for 5 rod aluminum pedals, each with different strengths and properties.

- Tempering : Select the appropriate alloying state based on the required formability, strength and ease of fabrication.

- Thickness : Choose the appropriate thickness of aluminum pedals according to load requirements and traffic flow.

- Specifications : Ensure that aluminum pedals meet the necessary specifications such as ASTM B209 or EN 573-3 to ensure consistent quality and performance.

- Cost : Consider your project's budget and choose aluminum pedals that fit within your budget while still meeting the necessary requirements.

By considering these factors, you can choose the proper 5-bar aluminum pedal for your specific application that will provide the necessary strength, durability, and corrosion resistance while meeting your budget constraints.