- What is 2024 Aerospace Grade Aluminum Plate?

- Aerospace Grade Aluminum 2024 Aluminum Plate Specifications

- Mechanical Properties Of Aircraft Grade Aluminum 2024 Aluminum Plate

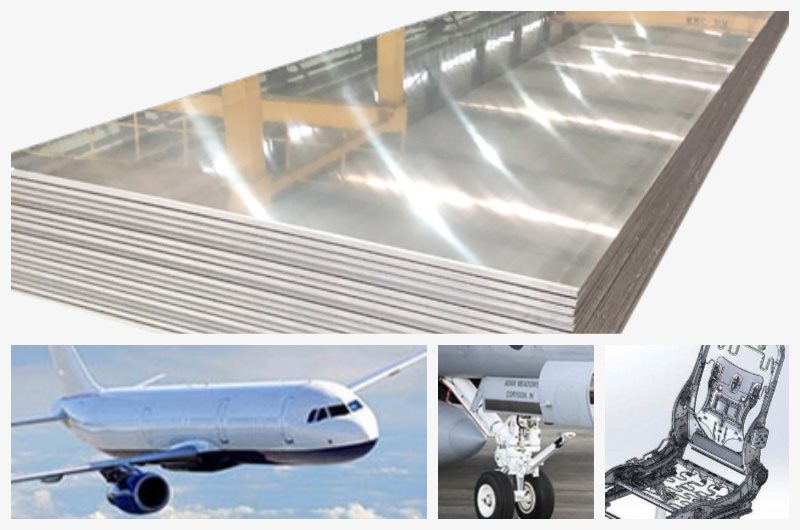

- What are the Common Applications of 2024 Aerospace Aluminum Plates?

- Detailed Introduction to 2024 Aerospace Aluminum Plate Applications

- 2024 Aerospace Aluminum Plate Alternatives

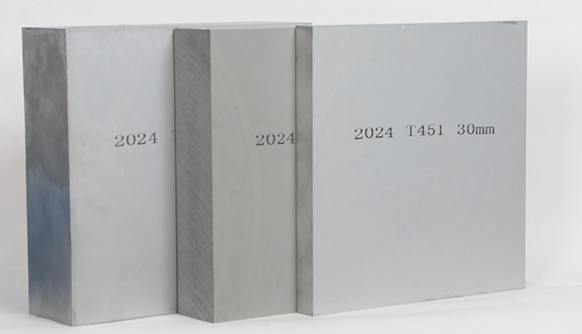

- Hot Sale 2024 Aircraft Grade Aluminum Plate

- Aircraft Grade Aluminum Plate 2024 Chemical Composition Limits

- Frequently Asked Questions (FAQ) about 2024 Aerospace Aluminum Plate

What is 2024 Aerospace Grade Aluminum Plate?

2024 aluminum is a high-strength, heat-treatable aluminum alloy that is part of the 2xxx series of aluminum alloys known for its excellent strength-to-weight ratio, good fatigue resistance and good machinability.

2024 aluminum is used in aerospace in a variety of forms including plate, sheet, rod and shapes.

- Easy to form, machine and weld for a variety of aircraft components such as wings, fuselage and structural supports.

- It is also used in other applications such as bicycle frames, truck wheels and sports equipment.

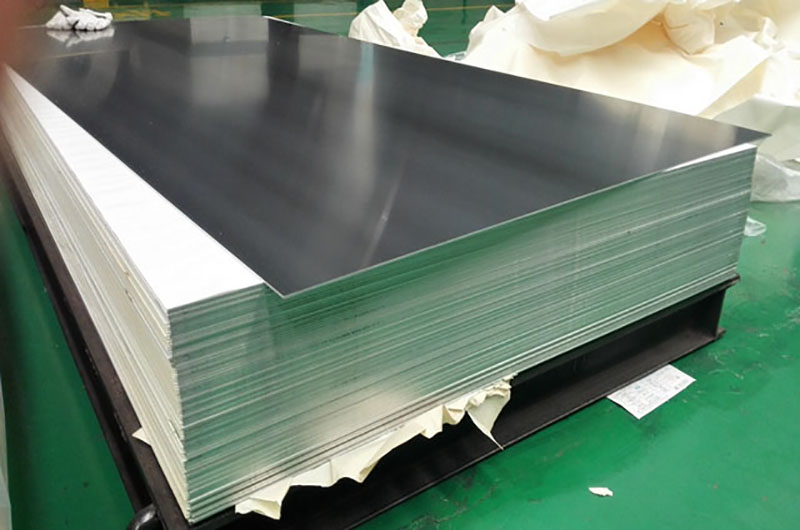

Aerospace Grade Aluminum 2024 Aluminum Plate Specifications

Aircraft Grade Aluminum 2024 is a popular material used in aircraft and aerospace applications.

- Thickness : Aerospace-grade aluminum 2024 aluminum sheet typically ranges in thickness from 0.016" to 0.250" (0.41mm to 6.35mm).

- Width and Length : Common widths range from 24" to 48" (609.6mm to 1219.2mm), while common lengths range from 72" to 144" (1828.8mm to 3657.6mm).

- Status : Usually available in 2024-T3, 2024-T4 and 2024-T6 tempers.

- Surface treatment : polished, painted or anodized.

- Standards : ASTM B209 and AMS-QQ-A-250/5.

Mechanical Properties Of Aircraft Grade Aluminum 2024 Aluminum Plate

| ALLOY | TEMPER | DIRECTION | THICKNESS(MM) |

TENSILE STRENGTH(MM) RM(MPA) |

YIELD STRENGTH RP0.2(MPA) |

BREAKING ELONGATION A50% |

STANDARD |

| 2024 thick plate | T351 | LT | 6-102 | 460-495 | 320-340 | 12.5-21.5 | AMS-QQ-A-250/4 |

| 2024 thin plate | T4 | - | 0.3-3.5 | 430-450 | 280-310 | 18-21 |

GB/T380 EN485 ASTM B209 |

What are the Common Applications of 2024 Aerospace Aluminum Plates?

Aerospace aluminum plates made from 2024 alloy are used in the construction of aircraft structural components, such as wing and fuselage skins, bulkheads, and structural frames.

| Alloy | Applications |

|---|---|

| 2024-T351 | Wing Skins |

| 2024-T3511 | Fuselage Frames |

| 2024-T3511, 2024-T8511 | Tailcone Components |

| 2024-T3, 2024-T4 | Door Components |

| 2024-T351 | Vertical Tail Ribs and Spars |

| 2024-T351, 2024-T851 | Horizontal Tail Fittings |

| 2024-T3, 2024-O | Leading Edge Skins |

| 2024-T3511 | Fuselage Frames |

| 2024-O, 2024-T3, 2024-T4 | Fuselage Brackets |

| 2024-T3, 2024-T4 | Fuselage Skins |

| 2024-T3, 2024-T4 | Door Components |

| 2024-T3, 2024-T4 | Engine Cowl Skins |

| 2024-T3 | Seat Pans |

Detailed Introduction to 2024 Aerospace Aluminum Plate Applications

Common Tempers: T3 and T4

2024 aluminum is available in T3 and T4 tempers, known for their high plasticity, fatigue resistance, and toughness. However, they have poor corrosion resistance.

2024 Aerospace Aluminum Plate for Aircraft Structural Parts

- Material Selected: 2024-T3

- Reason for Selection: 2024-T3 provides the necessary high strength and fatigue resistance needed for the structural integrity of fuselages, wings, and ribs. The T3 temper enhances the alloy's toughness and plasticity, making it ideal for these critical components.

| Specific application structure | Material Selected | Specifications Applied |

| 2024 Aerospace Aluminum Plate for Fuselages | 2024-T3 | Thickness ranges from 1.6 mm to 6.0 mm, with specific dimensions tailored to the structural requirements of the aircraft. |

| 2024 Aerospace Aluminum Plate for Wings | ||

| 2024 Aerospace Aluminum for Ribs |

2024 Aerospace Aluminum Plate for High-Temperature Applications

- Material Selected: 2024-T4

- Reason for Selection: 2024-T4 is chosen for its excellent high-temperature resistance and comprehensive performance after artificial aging. It has a minimal tendency to soften at high temperatures, making it suitable for prolonged exposure to temperatures above 121°C.

| Specific application structure | Material Selected | Specifications Applied |

| 2024 Aerospace Aluminum for Skins of Commercial and Military Aircraft | 2024-T4 | Thickness varies from 0.8 mm to 4.0 mm, depending on the design requirements for skins and engine components. |

| 2024 Aerospace Aluminum for Engines of Commercial and Military Aircraft |

2024 Aerospace Aluminum Plate for Hydraulic Systems

- Material Selected: 2024-T351

- Reason for Selection: The T351 temper provides superior fatigue resistance, which is crucial for withstanding the immense stresses and pressures in hydraulic systems. This makes 2024-T351 a viable candidate for large hydraulic manifolds.

| Specific application structure | Material Selected | Specifications Applied |

| 2024 Aerospace Aluminum for Large Hydraulic Manifolds | 2024-T351 | Plates ranging from 6.0 mm to 25.0 mm in thickness are commonly used to ensure the structural integrity and performance of the hydraulic system. |

2024 Aerospace Aluminum Plate Alternatives

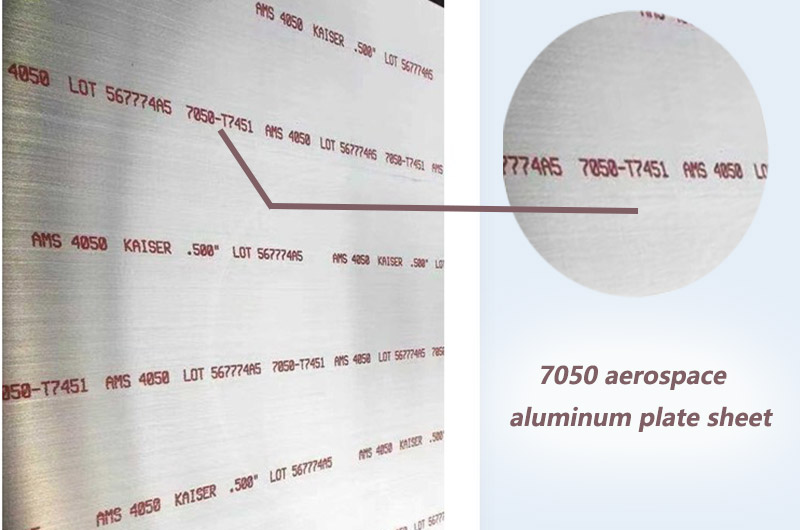

Yes, there are several other aluminum alloys used in aerospace, including 6061, 7075, and 7050, each with its own set of properties and applications.

Hot Sale 2024 Aircraft Grade Aluminum Plate

2024 o Aerospace Aluminum Plate

- 2024 o is the annealed temper, the softest and most ductile state of the alloy.

- 2024 O Aerospace Aluminum Sheet low strength.

- Application : Not recommended for structural applications. Cutting edge skin, fuselage bracket

2024-T3 Aerospace Aluminum Plate

- The 2024 aluminum plate in the T3 state is hardened and naturally aged.

- 2024-T3 Aerospace Aluminum Plate has high strength and good ductility.

- Application : Widely used in aircraft components and parts, such as wings, flaps, beams, ribs, leading edges, etc.

2024-T351 Aerospace Aluminum Plate

- The 2024 aluminum plate in the T351 state has been artificially aged on the basis of the T3 state.

- 2024-T351 Aerospace Aluminum Plate has higher strength and hardness, but relatively, ductility and toughness are slightly reduced.

- Application : Commonly used in aircraft components and parts that require high strength and corrosion resistance, such as structural parts, connectors, bottom plates, etc.

2024-T3511 Aerospace Aluminum Plate

- The 2024 aluminum sheet in the T3511 condition is similar to the T351 condition, but it is also stretch-leveled for better flatness and surface finish.

- Compared with T351 state, 2024-T3511 Aerospace Aluminum Plate is more excellent in plane performance and residual stress of material.

- Application : It is suitable for some aircraft structural parts that require high material surface quality and planarity, such as fuselage shells, wing plates, etc.

2024-T4 Aerospace Aluminum Plate

- The 2024 aluminum plate in the T4 state is solution heat treated and tempered by natural aging.

- 2024-T4 Aerospace Aluminum Plate is stronger than T3 and is used for aerospace structural applications.

- Applications : door assemblies, fuselage brackets, fuselage skins, door assemblies, engine cover skins.

2024 T851 Aerospace Aluminum Plate

- The 2024 aluminum plate in T851 state has been treated with natural aging and artificial aging.

- 2024 T851 Aerospace Aluminum Plate offers high strength and stiffness.

- Application : Usually used in aircraft components and components that require high strength and corrosion resistance, such as structural parts, connectors, bottom plates, etc.

2024 T8511 Aerospace Aluminum Plate

- The 2024 aluminum sheet in the T8511 condition is similar to the T851 condition, but it is also stretch-leveled for better flatness and surface finish.

- Compared with the T851 state, 2024 T8511 Aerospace Aluminum Plate is more excellent in plane performance and residual stress of the material.

- Application : It is suitable for some aircraft structural parts that require high material surface quality and planarity, such as fuselage shells, wing plates, etc.

2024 aluminum sheets all have high strength and hardness, but are slightly different in plane performance and surface finish. Therefore, the choice needs to be made according to the specific application and performance requirements.

- If you have higher requirements for plane performance and surface finish, you can choose 2024 T8511.

- If performance requirements are more important, you can choose 2024 T851.

Aircraft Grade Aluminum Plate 2024 Chemical Composition Limits

| ALLOY | SI | FE | CU | MN | MG | CR | ZN | ZR | TI | STANDARD |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | - | 0.15 | GB/AMS/EN |

Frequently Asked Questions (FAQ) about 2024 Aerospace Aluminum Plate

What is the Cost Range for 2024 Aerospace Aluminum Plates?

The cost of 2024 aerospace aluminum plates can vary depending on factors such as size, thickness, quantity, and supplier. It's important to obtain quotes from multiple suppliers for accurate pricing.

How is 2024 Aluminum Plate Manufactured?

2024 aluminum plates are typically produced through a process called hot rolling or cold rolling, followed by heat treatment to achieve the desired mechanical properties.

How is 2024 Aluminum Alloy Maintained and Inspected in Aerospace Applications?

Routine inspections and maintenance practices are essential to ensure the structural integrity of 2024 aluminum components in aerospace. Non-destructive testing methods like ultrasound and X-ray are often used for inspection.

Are there any Environmental Concerns Related to 2024 Aluminum Alloy in Aerospace?

Aluminum is generally considered environmentally friendly due to its recyclability. However, the manufacturing processes may have environmental impacts, which can be minimized through sustainable practices.